Textured paint

A textured paint, lightweight clay brick technology, applied in the field of textured paint, can solve the problems of short open time, narrow application range, easy to appear joints and other problems, achieve long open time, good flame retardant performance, and increase the effect of fire rating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

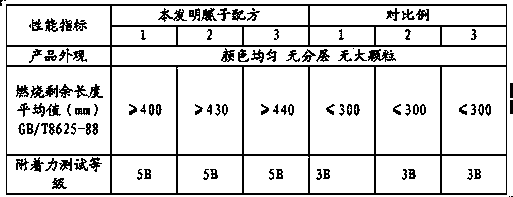

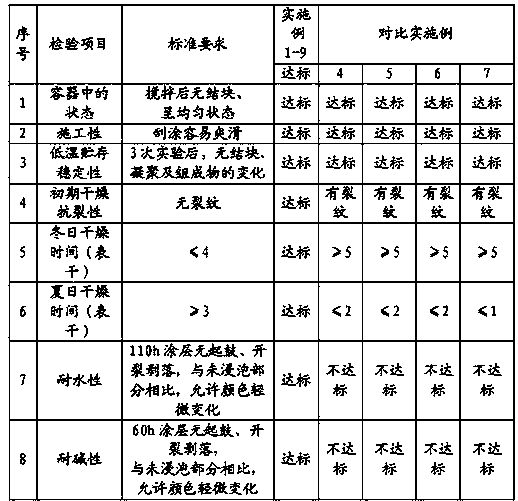

Embodiment 1

[0060] Texture paint formula: 10 parts of water, 40 parts of composite latex, 15 parts of quartz sand, 8 parts of silicon-based active glue, 6 parts of putty, 12 parts of cellulose ether, 2 parts of anti-mold preservative, 1 part of organic zirconium complex, 3 parts of dimethylaniline, 7 parts of pentaerythritol;

[0061] Wherein, the composite latex contains 10% polyurethane resin, 50% polyacrylate resin, 20% polyvinyl alcohol resin, 15% epoxy resin, and 5% emulsifier.

[0062] The putty is formulated according to the putty recipe one.

Embodiment 2

[0064] The putty is according to the formula of putty formula 2.

Embodiment 3

[0066] The putty follows the putty recipe three recipes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com