Microbial agent for pretreatment of straws and manure biogas

A technology of microbial inoculum and biogas fermentation, applied in microorganisms, microorganism-based methods, fermentation, etc., can solve the problems of incomplete research on bacterial antagonism, difficult to achieve ideal effects, and inability to play a role, and promote the mixing of straw and manure. Anaerobic fermentation process, shortened fermentation cycle, easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Straw and manure biogas fermentation pretreatment The microorganisms in the microbial agent are mainly screened from various cellulose-degrading bacteria and lignin-degrading bacteria in the fermentation biogas slurry, various bacteria, actinomycetes, and fungi in mature compost and tree soil And get.

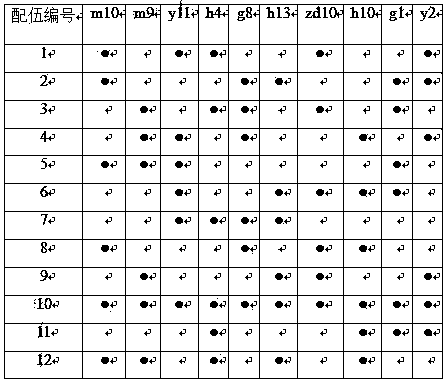

[0023] (1) Separation and screening of microorganisms

[0024] For the separation and screening of cellulose-degrading bacteria and lignin-degrading bacteria, the existing biogas fermentation tank in the laboratory was used as the source of microorganisms, and straw powder was used as the only carbon source to prepare inorganic salt medium, and the dilution plate method was used to separate different microorganisms. After culturing at 32°C, 12 strains of aerobic and facultative anaerobic bacteria were isolated. Then, use each microorganism to pretreat the straw, and measure the overall degradation rate of cellulose, hemicellulose, and lignin to screen out six types with...

Embodiment 3

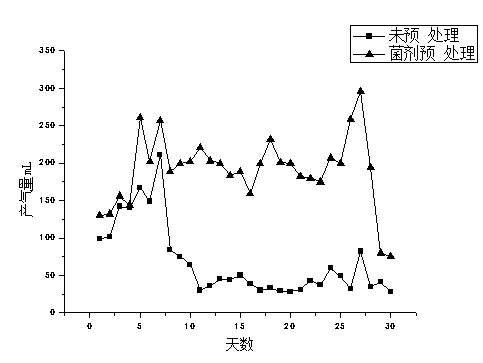

[0050] The dominant bacterial agent (microorganism No. 6 in Example 2) screened out according to the amount of gas produced was mixed with straw in different proportions for pretreatment, and placed in a constant temperature incubator at 37°C for anaerobic fermentation. According to the amount of biogas, the optimal feed ratio (mass ratio) of inoculant to straw is finally determined.

[0051] The mass ratio of dry powder inoculum to straw was 1:1000 for No. 1, 1:500 for No. 2, 1:100 for No. 3, 1:50 for No. 4 and 1:20 for No. 5, and 15 g of straw was uniformly added.

[0052] Experiments show that the gas production is the highest when the mass ratio of dry powder bacterial agent to straw is 1:50. Therefore, choose 1:50 as the best feed ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com