Nitrogen doped titanium dioxide nanotube array enzyme electrode and preparation method and application thereof

A nanotube array, titanium dioxide technology, applied in the field of electrochemical materials, can solve the problems of poor electrical conductivity, poor hydrophilicity, reduced enzyme activity of enzyme electrodes, etc., and achieve the effects of good hydrophilicity, good conductivity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

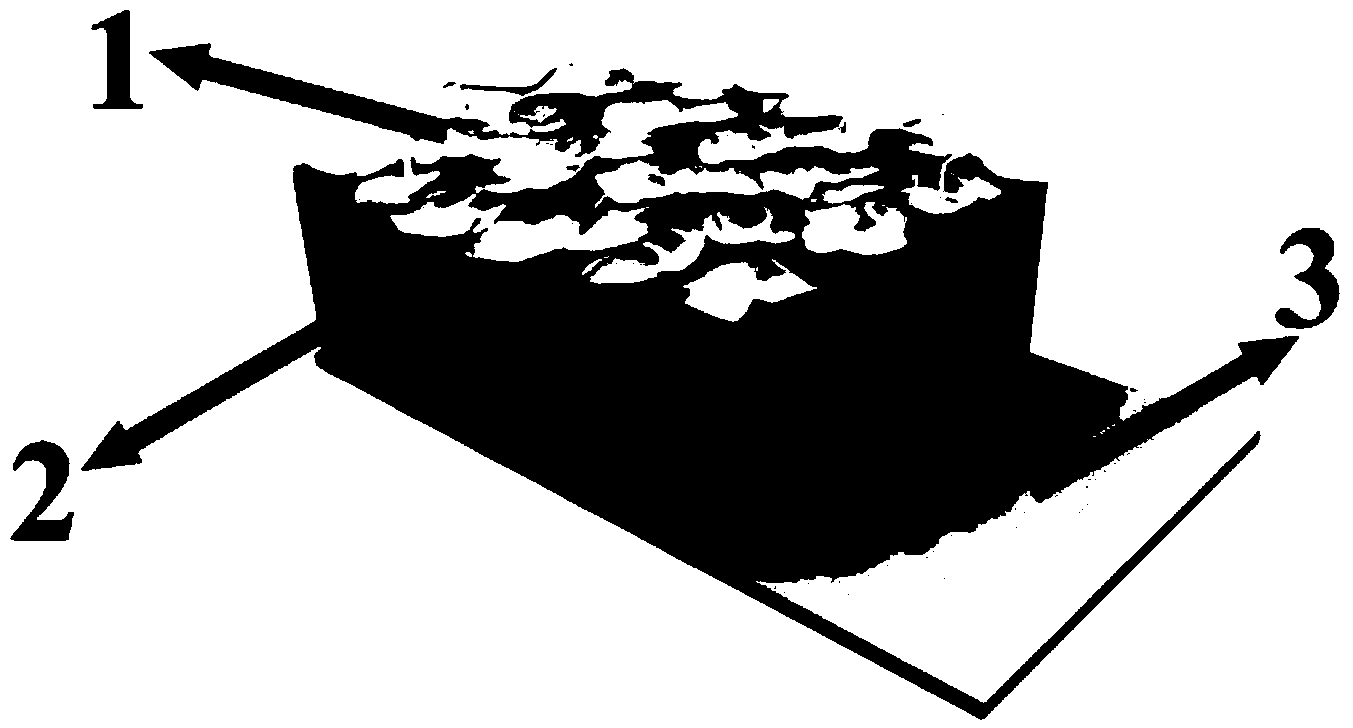

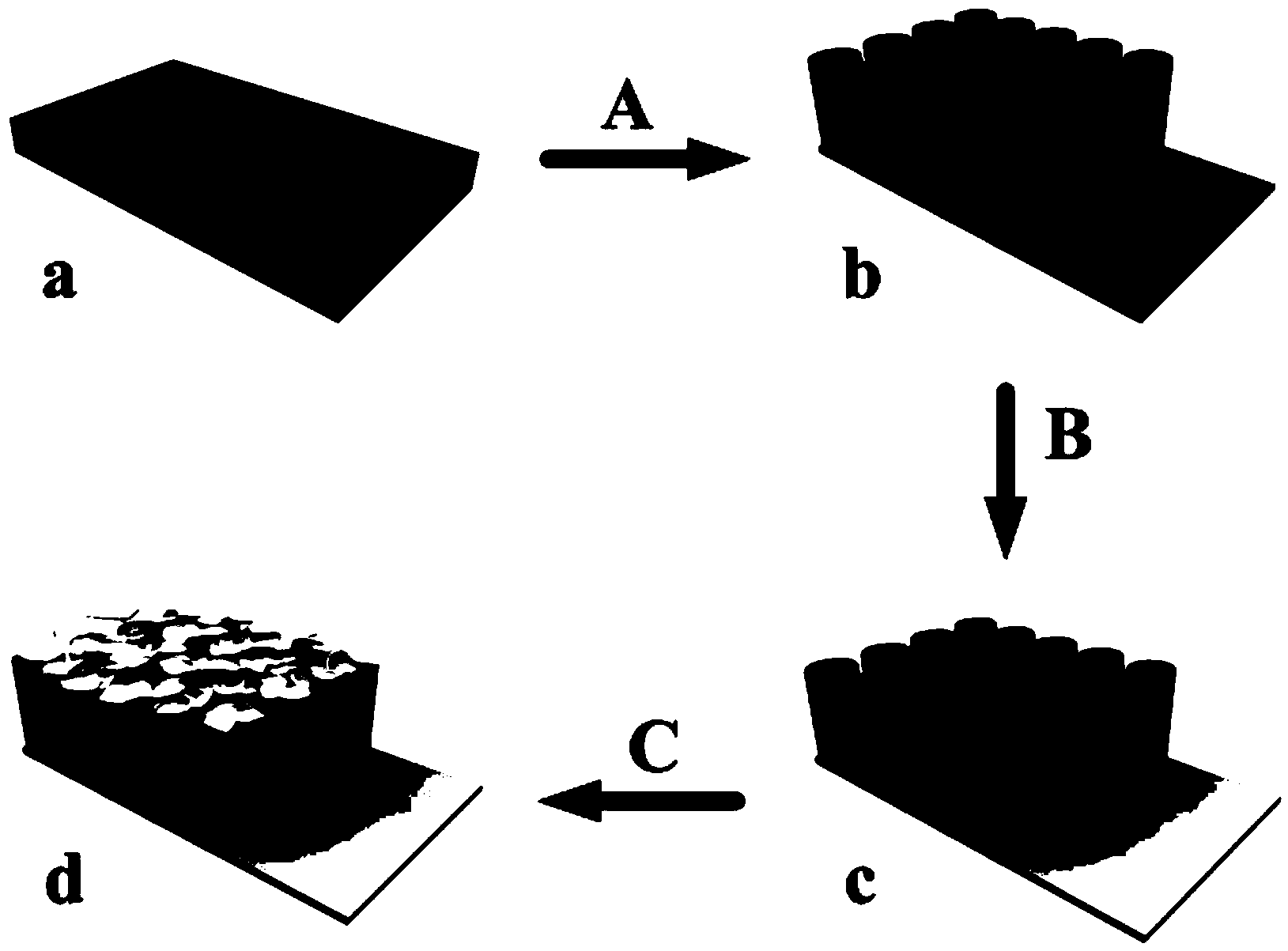

[0038] The preparation process of glucose oxidase-nitrogen-doped titanium dioxide nanotube array enzyme electrode, see figure 2 , including the following steps:

[0039] (1) Synthesis of titanium dioxide nanotube arrays by constant voltage anodic oxidation method: In a two-electrode electrochemical reaction system, titanium sheets are used as anodes, platinum sheets are used as cathodes, and a mixture of ethylene glycol, water, and ammonium fluoride is used for electrolysis. solution, anodic oxidation reaction was carried out to prepare titanium dioxide nanotube arrays; the conditions of the constant voltage anodic oxidation method were as follows: the oxidation voltage was 60V, the oxidation time was 3h, the reaction temperature was 25°C, and the reaction electrolyte contained water and ammonium fluoride Ethylene glycol organic solution, the mass fraction of water is 0.9%, and the mass fraction of ammonium fluoride is 0.25%.

[0040](2) High-temperature calcination treatmen...

Embodiment 2

[0045] The preparation process of glucose oxidase-nitrogen-doped titanium dioxide nanotube array enzyme electrode, see figure 2 , including the following steps:

[0046] (1) Synthesis of titanium dioxide nanotube arrays by constant voltage anodic oxidation method: In a two-electrode electrochemical reaction system, titanium sheets are used as anodes, platinum sheets are used as cathodes, and a mixture of ethylene glycol, water, and ammonium fluoride is used for electrolysis. solution, anodic oxidation reaction was carried out to prepare titanium dioxide nanotube arrays; the conditions of the constant voltage anodic oxidation method were as follows: the oxidation voltage was 60V, the oxidation time was 2h, the reaction temperature was 23°C, and the reaction electrolyte contained water and ammonium fluoride Ethylene glycol organic solution, the mass fraction of water is 1.8%, and the mass fraction of ammonium fluoride is 0.2%.

[0047] (2) High-temperature calcination treatmen...

Embodiment 3

[0051] The preparation process of glucose oxidase-nitrogen-doped titanium dioxide nanotube array enzyme electrode, see figure 2 , including the following steps:

[0052] (1) Synthesis of titanium dioxide nanotube arrays by constant voltage anodic oxidation method: In a two-electrode electrochemical reaction system, titanium sheets are used as anodes, platinum sheets are used as cathodes, and a mixture of ethylene glycol, water, and ammonium fluoride is used for electrolysis. solution, anodic oxidation reaction was carried out to prepare titanium dioxide nanotube arrays; the conditions of the constant voltage anodic oxidation method were as follows: the oxidation voltage was 60V, the oxidation time was 1h, the reaction temperature was 27°C, and the reaction electrolyte contained water and ammonium fluoride Ethylene glycol organic solution, the mass fraction of water is 2.7%, and the mass fraction of ammonium fluoride is 0.30%.

[0053] (2) High-temperature calcination treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com