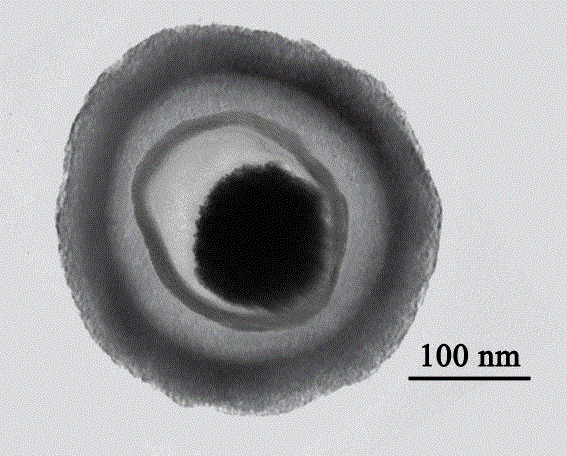

Preparation method of double-shell core-shell structured composite nanoparticle with with cavity

A technology of nanocomposite particles and core-shell structure, which is applied in the field of advanced nanocomposite particles to reduce costs and increase adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

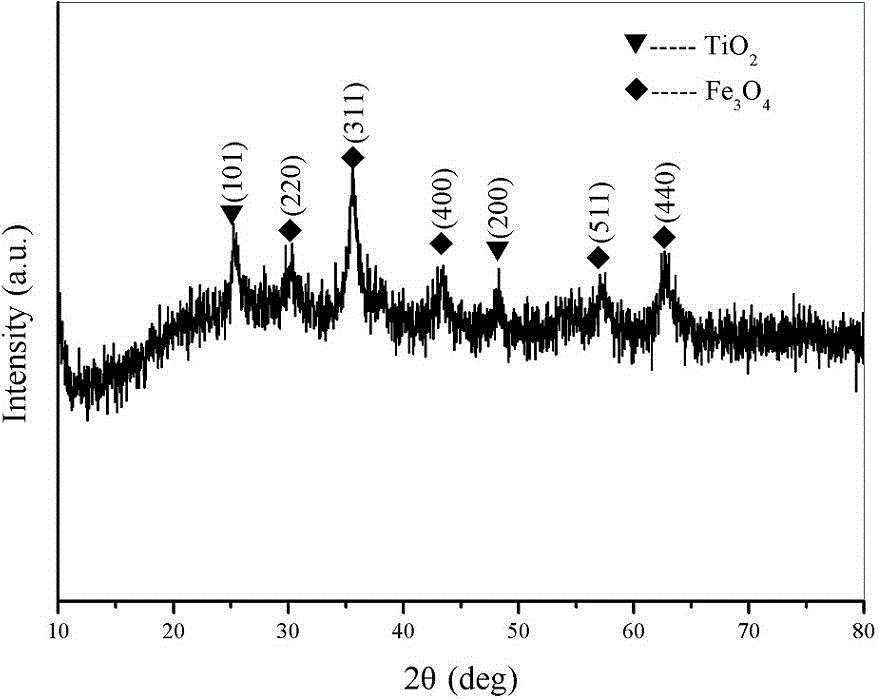

[0023] (1) Add 1g of ferric chloride hexahydrate, 0.1g of sodium citrate, and 1g of sodium acetate into a mixture of 50ml of ethylene glycol and 30ml of diethylene glycol, stir at room temperature until dissolved, and then transfer the solution to polytetrafluoroethylene In the reaction kettle, react at a temperature of 180° C. for 10 hours to obtain a black product. The black product was washed three times with deionized water and absolute ethanol respectively, and dried at 30° C. for 10 hours to finally obtain iron ferric oxide nanoparticles;

[0024] (2) Ultrasonically disperse 0.04g of ferric oxide nanoparticles obtained in step (1), 40ml of absolute ethanol, 5ml of water, and 1ml of ammonia water in a three-necked flask, stir at room temperature for 10 minutes, and then add 0.2ml of ethyl orthosilicate Add the ester dropwise into the flask, continue stirring for 6 hours, collect the product after the reaction is fully completed, wash the product three times with absolute ...

Embodiment 2

[0029] (1) Add 1g of ferric chloride hexahydrate, 0.5g of sodium citrate, and 3g of sodium acetate into a mixture of 60ml of ethylene glycol and 20ml of diethylene glycol, stir at room temperature until dissolved, then transfer the solution to an autoclave, React at 200°C for 10 hours to obtain a black product. The black product was washed three times with deionized water and absolute ethanol respectively, and dried at 30° C. for 10 hours to finally obtain iron ferric oxide nanoparticles;

[0030] (2) Ultrasonically disperse 0.04g of iron ferric oxide nanoparticles obtained in step (1), 60ml of absolute ethanol, 10ml of water, and 2ml of ammonia water in a three-necked flask, stir at room temperature for 10 minutes, and then add 0.5ml of methyl orthosilicate Add the ester dropwise into the flask, continue stirring for 10 hours, collect the product after the reaction is fully completed, wash the product three times with absolute ethanol and deionized water, and dry at 40°C for...

Embodiment 3

[0035] (1) Add 1g of ferric chloride hexahydrate, 0.1g of sodium citrate, and 1g of sodium acetate into a mixture of 50ml of ethylene glycol and 30ml of diethylene glycol, stir at room temperature until dissolved, then transfer the solution to an autoclave, React at 220°C for 10 hours to obtain a black product. The black product was washed three times with deionized water and absolute ethanol respectively, and dried at 30° C. for 10 hours to finally obtain iron ferric oxide nanoparticles;

[0036] (2) Ultrasonically disperse 0.04g of iron ferric oxide nanoparticles obtained in step (1), 100ml of absolute ethanol, 8ml of water, and 2.8ml of ammonia water in a three-necked flask, stir at room temperature for 10 minutes, and then add 1ml of acrylic orthosilicate Add the ester dropwise into the flask, continue stirring for 12 hours, collect the product after the reaction is fully completed, wash the product three times with absolute ethanol and deionized water, and dry at 40°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com