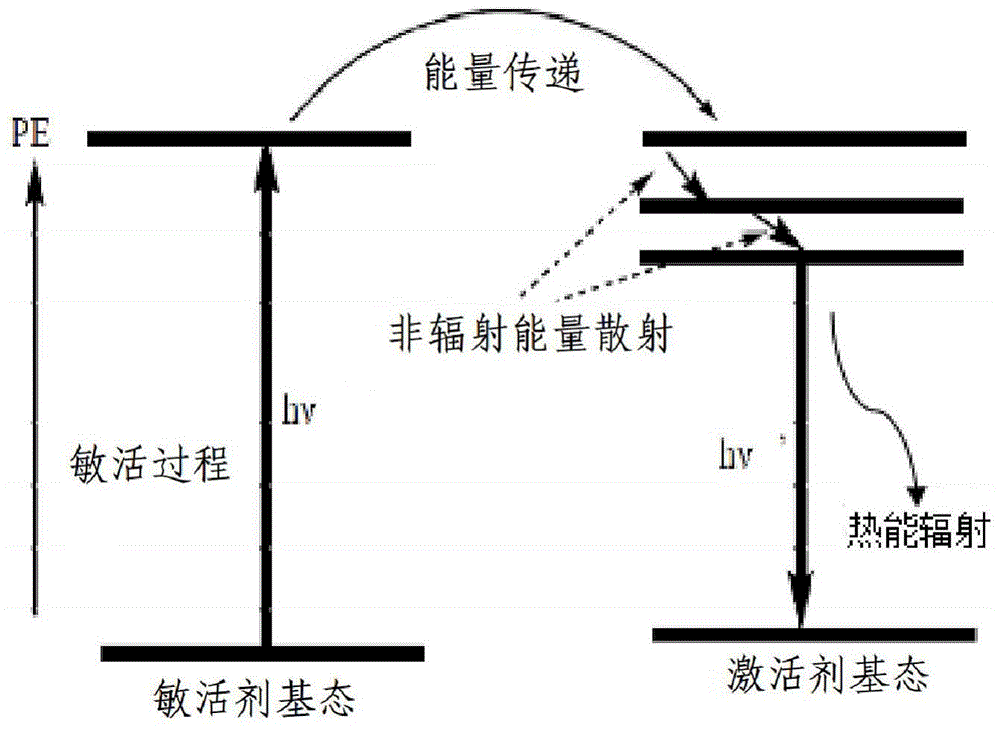

Indoor water-based paint capable of converting light energy into heat energy and preparation method thereof

A technology of light energy conversion and water-based coatings, which is applied in the direction of radiation-absorbing coatings and coatings. It can solve the problems of insufficient adhesion, prone to chromatic aberration and color spots in the paint film, so as to meet functional requirements, not easy to chromatic aberration, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

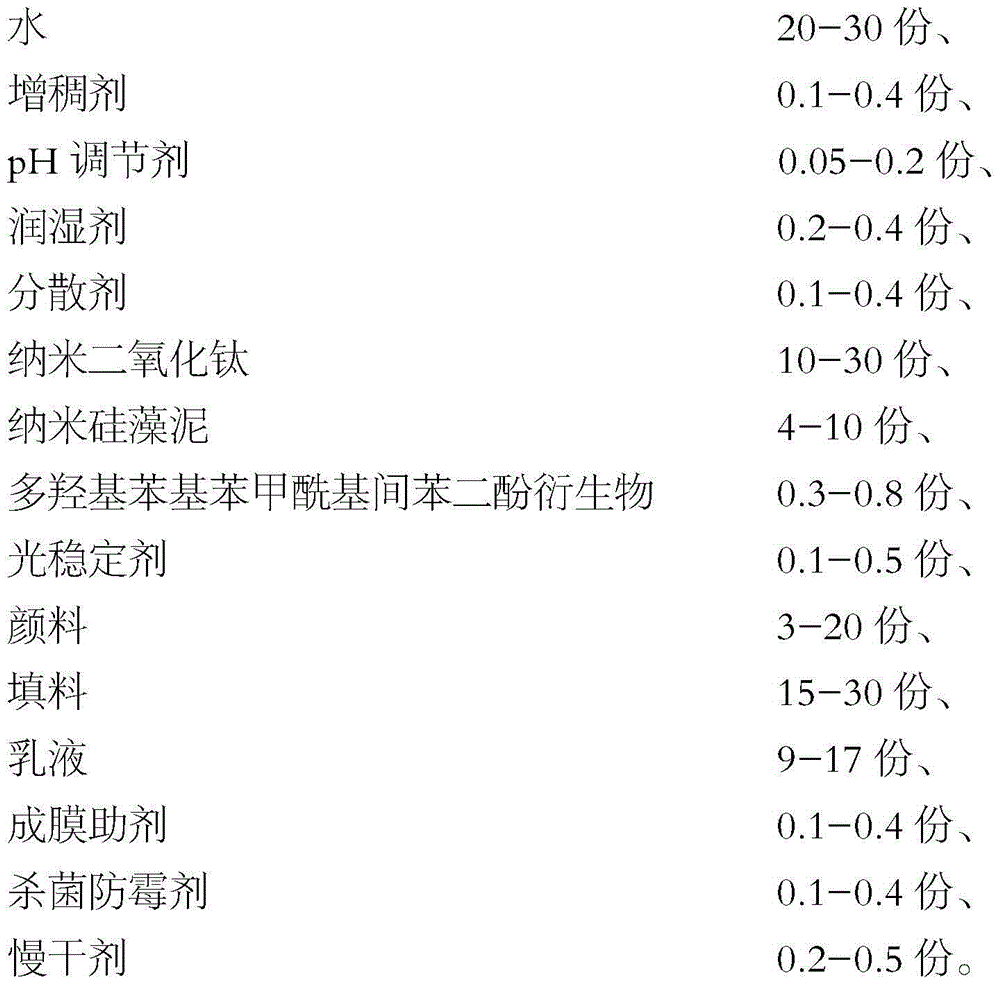

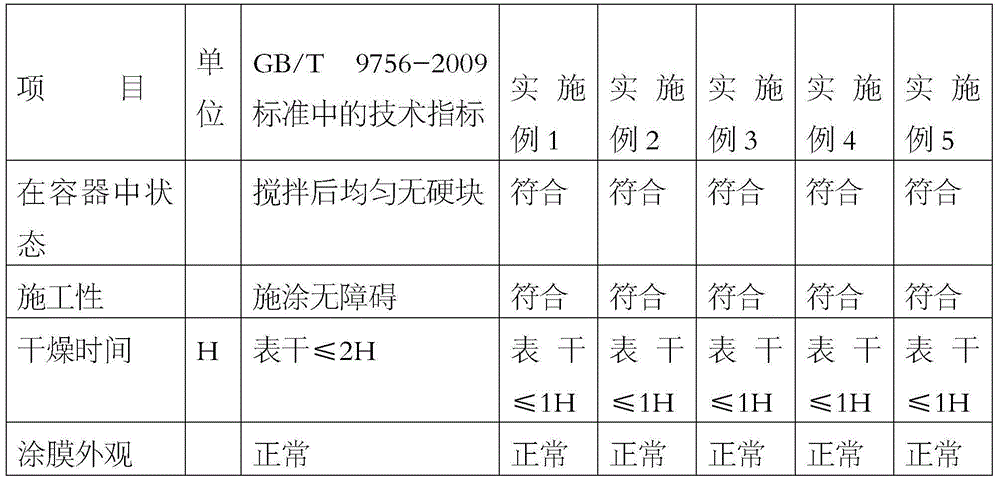

[0034] A light energy conversion thermal energy indoor water-based paint, which is prepared from the following raw materials according to the following mass ratio through the following steps:

[0035] After mixing 20 parts of water and 0.1 part of cellulose thickener, disperse at a speed of 450 rpm for 4-6 minutes, while dispersing, add 0.05 parts of 2-amino-2-methyl-1-propanol, 0.2 parts of α-phenylmethyl-ω-[(1,1,3,3-tetramethylbutyl)phenoxy]-poly(oxy-1,2-ethylene) ammonium acrylic acid homopolymer 0.1 part of salt and 0.1 part of bactericidal and antifungal agent, continue to disperse at 1100 rpm for 4-6 minutes, then add 30 parts of nano-titanium dioxide, 4 parts of nano-diatom mud, 3 parts of black pigment, heavy calcium 22 parts and 0.4 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, disperse at 1800-2200 rpm for 18-22 minutes; then add vinyl acetate-butyl acrylate 17 parts of polymer, 0.5 part of propylene glycol are dispersed at a speed of 400-800 rpm for 2-4...

Embodiment 2

[0036] Embodiment 2 (preferred embodiment)

[0037] A light energy conversion thermal energy indoor water-based paint, which is prepared from the following raw materials according to the following mass ratio through the following steps:

[0038] After mixing 25 parts of water and 0.2 parts of cellulose thickener, disperse at a speed of 500 rpm for 4-6 minutes, and add 0.1 parts of 2-amino-2-methyl-1-propanol while dispersing, 0.25 parts of α-phenylmethyl-ω-[(1,1,3,3-tetramethylbutyl)phenoxy]-poly(oxy-1,2-ethylene), ammonium acrylic acid homopolymer 0.2 parts of salt and 0.2 parts of bactericidal and antifungal agent, continue to disperse at a speed of 1200 rpm for 4-6 minutes, and then add 23 parts of nano-titanium dioxide, 6 parts of nano-diatom mud, and 8 parts of phthalocyanine blue pigment while dispersing , 23.7 parts of heavy calcium and 0.3 parts of 2,2,4-trimethyl-1,3 pentanediol monoisobutyrate, disperse at 1800-2200 rpm for 18-22 minutes; then add vinyl acetate- 12...

Embodiment 3

[0040] A light energy conversion thermal energy indoor water-based paint, which is prepared from the following raw materials according to the following mass ratio through the following steps:

[0041] After mixing 30 parts of water and 0.4 parts of cellulose thickener, disperse at a speed of 500 rpm for 4-6 minutes, while dispersing, add 0.2 parts of 2-amino-2-methyl-1-propanol, 0.3 parts of α-phenylmethyl-ω-[(1,1,3,3-tetramethylbutyl)phenoxy]-poly(oxy-1,2-ethylene), ammonium acrylic acid homopolymer 0.35 parts of salt and 0.3 parts of bactericidal antifungal agent, continue to disperse at a speed of 1200 rpm for 4-6 minutes, and then add 20 parts of nano-titanium dioxide, 8 parts of nano-diatom mud, 14 parts of iron yellow pigment, and disperse while dispersing. 15 parts of calcium and 0.3 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, dispersed at 1800-2200 rpm for 18-22 minutes; then add vinyl acetate-butyl acrylate 10.2 parts of ester polymer, 0.35 parts of pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com