Preparation method of metal ordered array nano structure based on plasmon-model metal reinforced fluorescence

A metal-enhanced fluorescence, ordered array technology, applied in the field of nanomaterials, can solve the problems of stability and repeatability of light-emitting devices, expensive equipment, and difficult to control AAO aperture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Preparation of silver array nanofilms

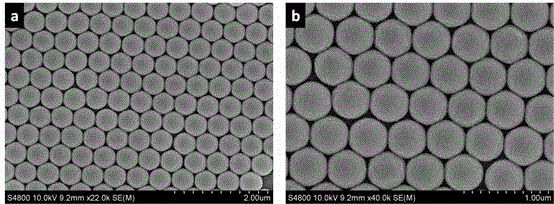

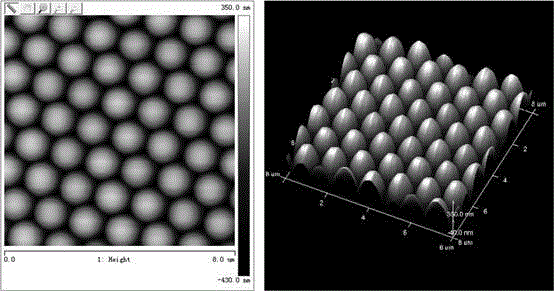

[0050] S1. Wash the glass slide, and after natural drying, take 15 μL of polystyrene microspheres with a mass fraction of 2.5% and a diameter of 400 nm, and drop-coat it on the glass slide in an area of 2cm×2cm;

[0051] S2. After natural drying at room temperature, slowly insert the glass sheet with polystyrene microspheres into distilled water at a certain angle. The polystyrene microspheres will float on the surface of distilled water and self-assemble to obtain a polystyrene film. ;

[0052] S3. After waiting for 5 minutes, completely remove the assembled polystyrene film from the aqueous solution with a quartz plate, and let it dry naturally at room temperature overnight;

[0053] S4. Put the above-mentioned quartz sheet with polystyrene film into the vacuum coating machine, and the vacuum degree is 6.5×10 -4 Under the vacuum state of Pa, deposit silver with a thickness of 40nm on the surface of the film at a depositi...

Embodiment 2

[0061] 1. Preparation of silver array nanofilms

[0062] S1. Wash the glass slide, and after natural drying, take 15 μL of polystyrene microspheres with a mass fraction of 2.5% and a diameter of 1000 nm, and drop-coat it on the glass slide in an area of 2cm×2cm;

[0063] S2. After natural drying at room temperature, slowly insert the glass sheet with polystyrene microspheres into distilled water at a certain angle. The polystyrene microspheres will float on the surface of distilled water and self-assemble to obtain a polystyrene film. ;

[0064] S3. After waiting for 5 minutes, completely remove the assembled polystyrene film from the aqueous solution with a quartz plate, and let it dry naturally at room temperature overnight;

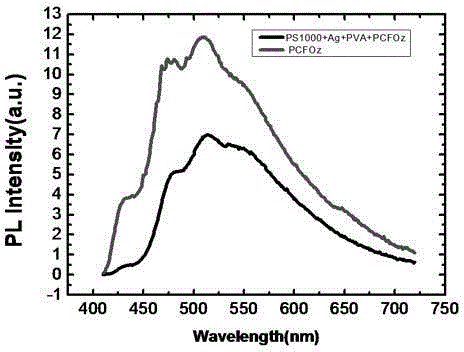

[0065] S4. Put the above-mentioned quartz sheet with polystyrene film into the vacuum coating machine, and the vacuum degree is 6.5×10 -4 Under the vacuum state of Pa, deposit silver with a thickness of 40nm on the surface of the film at a deposit...

Embodiment 3

[0073] Preparation of gold array nano film, the steps are as follows:

[0074] S1. Wash the glass slide, and after natural drying, take 15 μL of polystyrene microspheres with a mass fraction of 2.5% and a diameter of 1000 nm, and drop-coat it on the glass slide in an area of 2cm×2cm;

[0075] S2. After natural drying at room temperature, slowly insert the glass sheet with polystyrene microspheres into distilled water at a certain angle. The polystyrene microspheres will float on the surface of distilled water and self-assemble to obtain a polystyrene film. ;

[0076] S3. After waiting for 5 minutes, completely remove the assembled polystyrene film from the aqueous solution with a quartz plate, and let it dry naturally at room temperature overnight;

[0077] S4. Put the above-mentioned quartz sheet with polystyrene film into the vacuum coating machine, and the vacuum degree is 6.5×10 -4 Under the vacuum state of Pa, deposit 20nm thick gold on the surface of the film accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com