Environment-friendly cardanol, urea synergistically modified phenolic resin and application thereof to high temperature resistant friction material

A friction material and phenolic resin technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of high brittleness, insufficient heat resistance, and susceptibility to oxidation of phenolic resin, and improve heat resistance and toughness. The effect of short time and low process temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

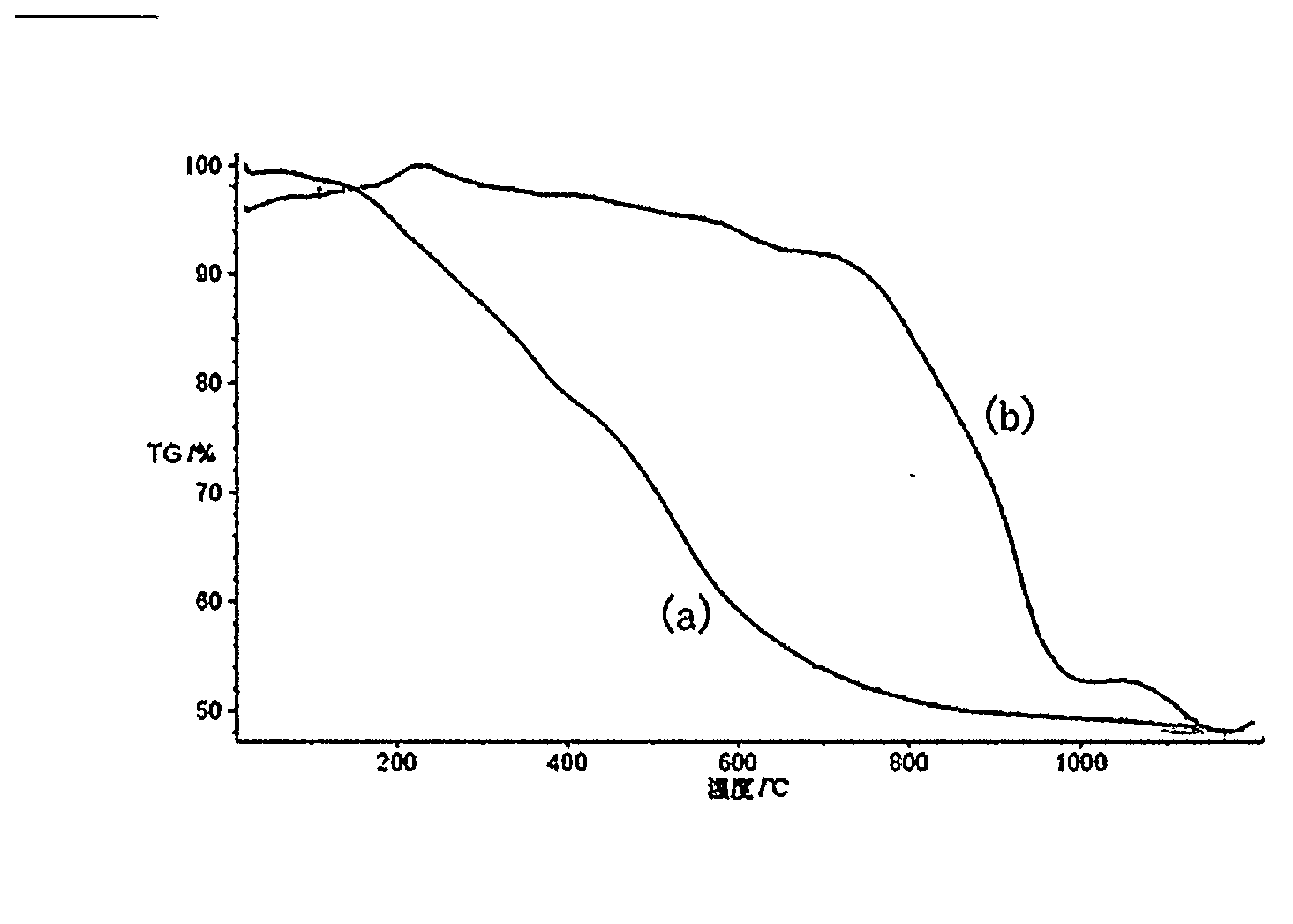

Image

Examples

Embodiment 1

[0030] An environmentally friendly double-modified phenolic resin for high-temperature resistant friction materials, the material components are 516 parts of phenol, 344 parts of cardanol, 645 parts of solid paraformaldehyde, 688 parts of urea, 16.34 parts of barium hydroxide, and 200 parts of ethanol.

[0031] Its preparation method comprises the following steps:

[0032] First, add 645 parts of paraformaldehyde, 516 parts of molten phenol, and 16.34 parts of barium hydroxide into a clean reactor equipped with a stirrer, reflux condenser and thermometer, and adjust the pH value between 8.1 and 8.2. Heat while stirring until the temperature rises to 65°C, then keep it warm for 60-70 minutes, and turn off the heating device.

[0033] When the temperature of the solution in the reactor drops from 65°C to 50°C, add urea immediately, and adjust the pH value of the solution to 3 with a saturated oxalic acid solution, raise the temperature to 75°C, the phenolic polycondensation reac...

Embodiment 2

[0035] An environmentally friendly double-modified phenolic resin for high-temperature resistant friction materials, the material components are 516 parts of resorcinol, 344 parts of cardanol, 645 parts of solid paraformaldehyde, 688 parts of urea, 16.34 parts of ammonia water, and 200 parts of ethanol.

[0036] Its preparation method is similar to that of Example 1, except that resorcinol is used instead of phenol, and ammonia water is used instead of barium hydroxide solution.

Embodiment 3

[0038] An environmentally friendly double-modified phenolic resin for high-temperature resistant friction materials, the material components are 516 parts of phenol, 344 parts of cardanol, 645 parts of solid paraformaldehyde, 688 parts of urea, 18.06 parts of barium hydroxide, and 200 parts of ethanol.

[0039] Its preparation method comprises the following steps:

[0040] First, add 645 parts of paraformaldehyde, 516 parts of molten phenol, and 18.06 parts of barium hydroxide into a clean reactor equipped with a stirrer, reflux condenser and thermometer, and adjust the pH value between 8.1 and 8.2. Heat while stirring until the temperature rises to 70°C, then keep it warm for 60-70 minutes, and turn off the heating device.

[0041] When the temperature of the solution in the reactor drops from 65°C to 50°C, urea is added immediately, and the pH value of the solution is adjusted to 4 with p-toluenesulfonic acid solution, and the temperature is raised to 75°C. The phenolic poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com