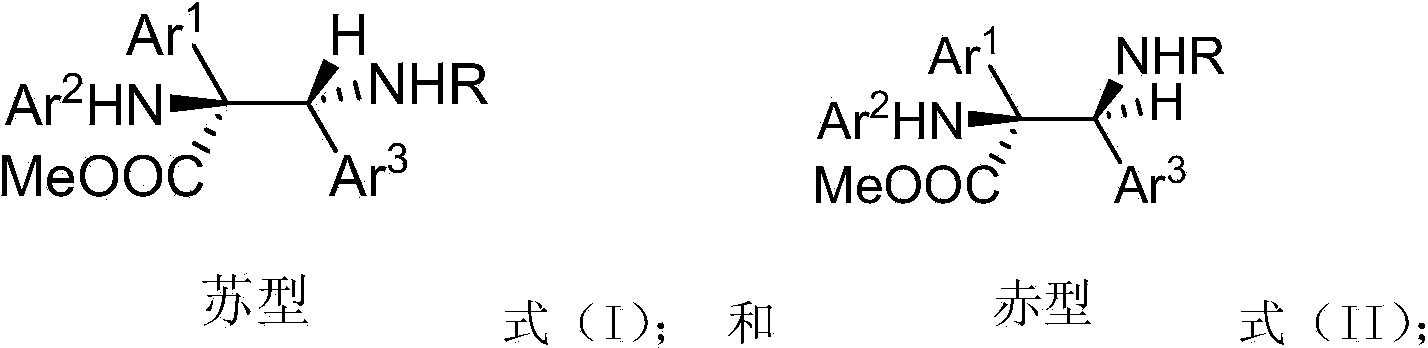

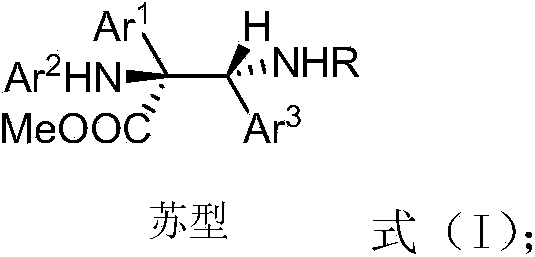

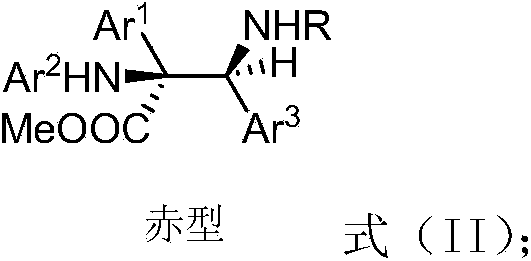

Alpha-quaternary carbon contained alpha,beta-diamino acid derivatives, and cocatalytic preparation method and application thereof

A diamine acid and derivative technology, applied in the field of pharmaceutical synthesis chemistry, can solve the problems of narrow reaction applicability, ineffective removal, harsh reaction conditions, etc., and achieve the effects of high efficiency and low cost, low synthesis cost, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]

[0051] Weigh N-p-toluenesulfonyl p-bromophenylimine (0.20mmol), rhodium acetate (1.00mg, 0.002mmol), squarylamide IIIA (0.02mmmol), aniline (0.30mmol), put them into a small test tube Reactor, add redistilled 5.6ml dichloromethane at room temperature. Weigh phenyldiazoacetate methyl ester (0.26mmol) and dissolve it in 2.8ml redistilled dichloromethane, and inject it into the reaction system through a peristaltic pump for 1 hour. The solvent was removed by rotary evaporation at 40°C, and the α, β-diamic acid derivatives at the α-position quaternary carbon were separated by column chromatography (eluent: petroleum ether: ethyl acetate = 1:20~1:5) Pure product A. Yield 53%, dr 50::50.

[0052]

[0053] Characterization of A:

[0054] 1 H NMR (400MHz, CDCl 3 )δ7.35-7.26(m, 4H), 7.26-7.13(m, 3H), 7.07(m, 2H), 7.00-6.84(m, 4H), 6.60(m, 1H), 6.44(d, J= 8.5Hz, 2H), 6.20(d, J=7.8Hz, 2H), 5.36(d, J=9.1Hz, 1H), 5.15(d, J=9.2Hz, 1H), 4.83(s, 1H), 3.56 (s, 3H), 2.26(s...

Embodiment 2

[0056]

[0057] Weigh N-p-toluenesulfonyl p-bromophenylimine (0.20mmol), rhodium acetate (1.00mg, 0.002mmol), squarylamide IIIB (0.02mmmol), aniline (0.30mmol), put them into a small test tube Reactor, add redistilled 5.6ml dichloromethane at room temperature. Weigh phenyldiazoacetate methyl ester (0.26mmol) and dissolve it in 2.8ml redistilled dichloromethane, and inject it into the reaction system through a peristaltic pump for 1 hour. The solvent was removed by rotary evaporation at 40°C, and the α, β-diamic acid derivatives at the α-position quaternary carbon were separated by column chromatography (eluent: petroleum ether: ethyl acetate = 1:20~1:5) Pure product A. Yield 52%, dr 50::50.

Embodiment 3

[0059]

[0060] Weigh N-p-toluenesulfonyl p-bromophenylimine (0.20mmol), rhodium acetate (1.00mg, 0.002mmol), squarylamide IIIC (0.02mmmol), aniline (0.30mmol), put them into a small test tube Reactor, add redistilled 5.6ml dichloromethane at room temperature. Weigh phenyldiazoacetate methyl ester (0.26mmol) and dissolve it in 2.8ml redistilled dichloromethane, and inject it into the reaction system through a peristaltic pump for 1 hour. The solvent was removed by rotary evaporation at 40°C, and the α, β-diamic acid derivatives at the α-position quaternary carbon were separated by column chromatography (eluent: petroleum ether: ethyl acetate = 1:20~1:5) Pure product A. Yield 50%, dr is 50::50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com