Controllable preparation method of carboxyl functionalized carbon nanotube

A carboxyl-functionalized, carbon nanotube technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low concentration of functional groups, difficult processing steps, and damage to the structure of carbon nanotubes, etc. To achieve the effect of uniform pipe diameter distribution, easy expansion of scale, and simple and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Weigh 2.741 grams of ferrocenedicarboxylic acid, add 100 grams of tetrachlorethylene and stir to form a uniform solution, transfer the solution into a stainless steel reaction kettle with a polytetrafluoroethylene substrate, and then raise the temperature to 160°C for 24 hours of constant temperature reaction. After the reaction, the filtered black product was washed three times with distilled water and ethanol in sequence, and finally placed in a vacuum drying oven at 100° C. for 12 hours to obtain the final product.

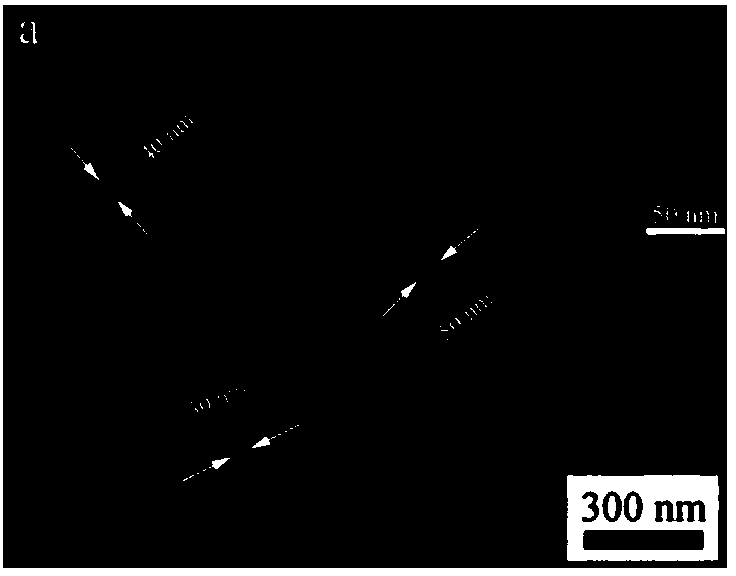

[0032] The scanning electron microscope (SEM) image of the final product is as Figure 1a As shown, under low magnification, the product is composed of a large number of one-dimensional fibrous structures, the thickness of which is between 30-50 nm and the distribution is relatively uniform. Figure 1a The upper right inset is a high magnification view of the port of the 1D fiber structure, showing that the 1D fiber structure is a hollow tubular structure i...

Embodiment 2

[0036] Weigh 0.372 grams of ferrocene and 2.193 grams of ferrocene dicarboxylic acid, add 100 grams of tetrachloroethylene and stir to form a uniform solution, transfer the solution into a stainless steel reaction kettle with a polytetrafluoroethylene substrate, and then heat up to 160 ° C for constant temperature reaction 24 hours. After the reaction, the filtered black product was washed three times with distilled water and ethanol in sequence, and finally placed in a vacuum drying oven at 100° C. for 12 hours to obtain the final product.

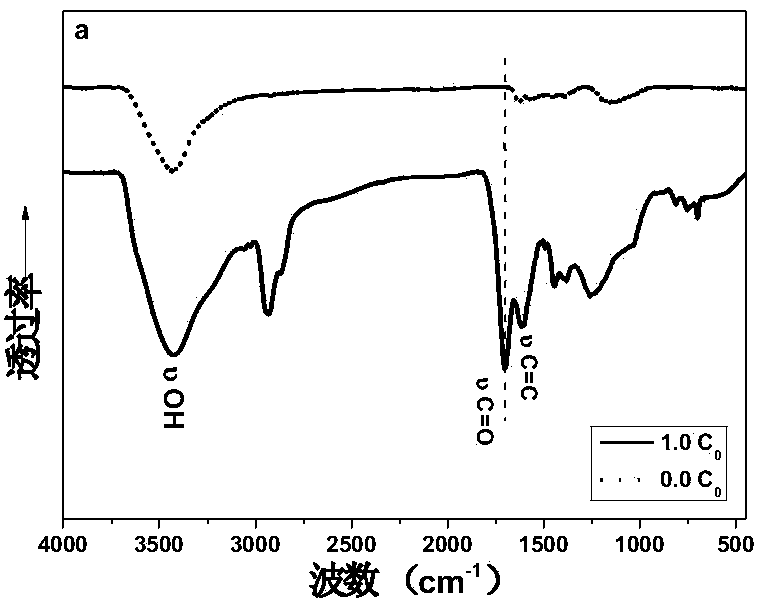

[0037] Similar to Example 1, SEM and TEM observations show that the final product is composed of a large number of one-dimensional tubular nanostructures, and FT-IR characterization results show that there are a large number of carboxyl groups in the product. The carboxyl concentration on the surface of the prepared carboxyl-modified carbon nanotubes was further determined by fluorescent labeling titration, Figure 2b Medium 0.8C 0 The ...

Embodiment 3

[0040] Weigh 0.744 grams of ferrocene and 1.645 grams of ferrocene dicarboxylic acid, add 100 grams of tetrachlorethylene and stir to form a uniform solution, transfer the solution into a stainless steel reaction kettle with a polytetrafluoroethylene substrate, and then heat up to 160°C for constant temperature reaction 24 hours. After the reaction, the filtered black product was washed three times with distilled water and ethanol in sequence, and finally placed in a vacuum drying oven at 100° C. for 12 hours to obtain the final product.

[0041] Similar to Example 1, SEM and TEM observations show that the final product is composed of a large number of one-dimensional tubular nanostructures, and FT-IR characterization results show that there are a large number of carboxyl groups in the product. Figure 2b Medium 0.6C 0 Curve corresponds to the fluorescence spectrum of the product obtained in Example 3, and the corresponding carbon tube surface carboxyl concentration is 2.06nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com