Insulation packaging material of high capacity film capacitor

A technology for packaging materials and film capacitors, applied in the field of packaging materials, can solve problems such as high thermal conductivity and low stress, and achieve the effects of improving thermal conductivity, reducing thermal stability, and good thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

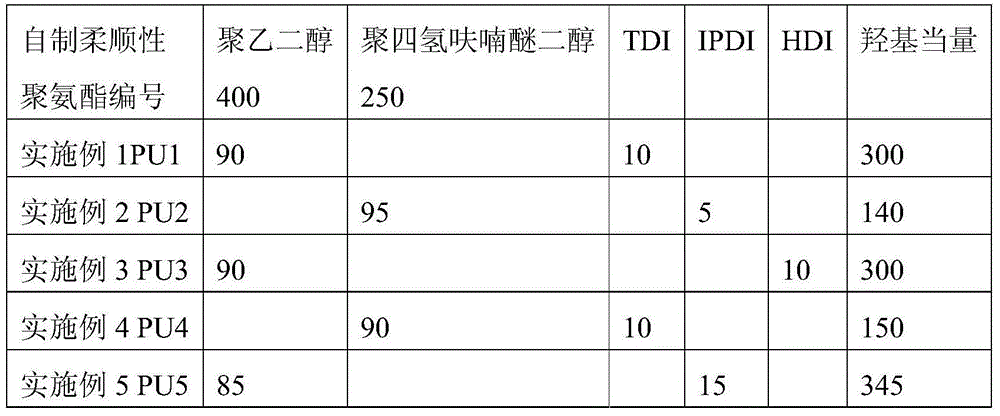

[0029] (1) First prepare flexible polyurethane: add polyethylene glycol 400 to the reaction kettle after removing water, and put it into the reaction kettle with nitrogen protection, react at 60°C for 7h until the viscosity no longer increases, cool down to 30°C, and filter out the material , to obtain homemade hydroxyl-terminated flexible polyurethane;

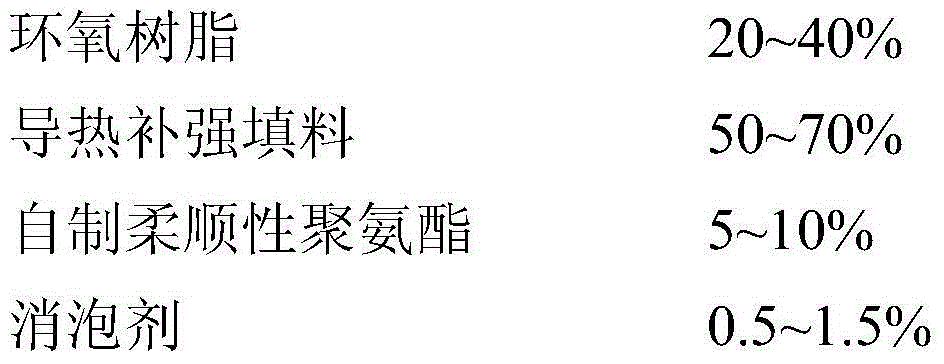

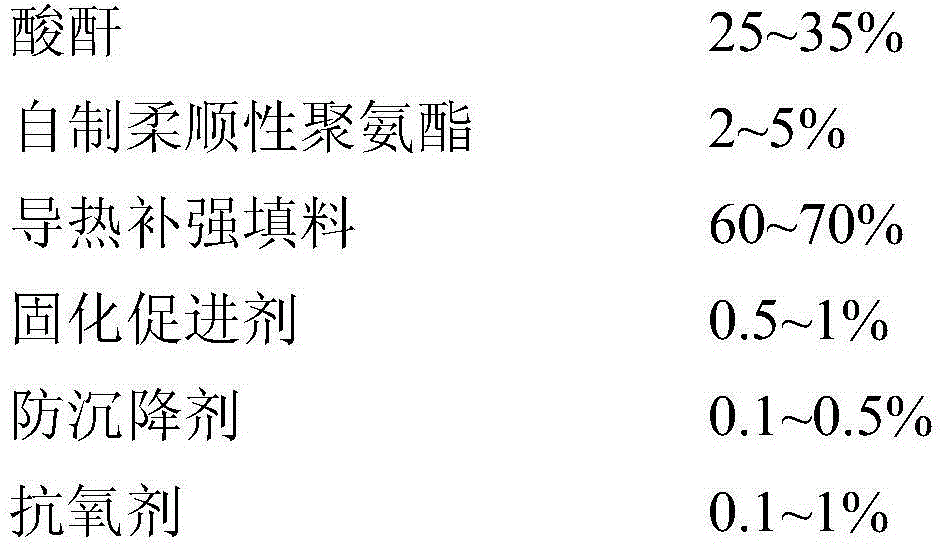

[0030] (2) Preparation of component A: epoxy resin (wherein bisphenol A epoxy resin E-51 accounts for 75%, alicyclic epoxy resin ERL-4221 accounts for 25%), self-made flexible polyurethane, needle-shaped silica fume Mix stone powder and defoamer BYK-A530 according to the mass percentage, add to the reaction kettle, heat up to 90°C and stir for 90 minutes, cool to 60°C, filter and discharge to obtain component A;

[0031] (3) Preparation of component B: Methyl tetrahydrophthalic anhydride, self-made flexible polyurethane, acicular wollastonite powder, modified imidazole, BYK-430, 2,6-di-tert-butyl-4-methylphenol according to t...

Embodiment 2

[0034] (1) First prepare flexible polyurethane: after removing polytetrahydrofuran ether diol 250, add IPDI to the reaction kettle, protect it with nitrogen, react at 65°C for 6h until the viscosity no longer increases, cool down to 35°C, and filter out materials, to obtain self-made hydroxyl-terminated flexible polyurethane;

[0035] (2) Preparation of component A: Mix bisphenol A epoxy resin E-51, self-made flexible polyurethane, silicon micropowder, and defoamer BYK-A530 according to the mass percentage, add it to the reaction kettle, heat up to 90°C and stir for 100 minutes, Cool to 55°C, filter and discharge to obtain component A;

[0036] (3) Preparation of component B: the mixture of methyl hexahydrophthalic anhydride and polyazelaic anhydride, self-made flexible polyurethane, silica powder, DMP-30, BYK-430, tetrakis (4-hydroxy-3,5-tert-butyl Phenylpropionate) pentaerythritol esters were mixed according to the mass percentage, added to a high-speed dispersion kettle, h...

Embodiment 3

[0039] (1) First prepare flexible polyurethane: remove polyethylene glycol 400 from water, add HDI to the reaction kettle, pass nitrogen protection, react at 70°C for 4 hours until the viscosity no longer increases, cool down to 40°C, and filter out the material , to obtain homemade hydroxyl-terminated flexible polyurethane;

[0040] (2) Preparation of component A: Mix alicyclic epoxy resin ERL-4221, self-made flexible polyurethane, aluminum oxide, and defoamer BYK-354 according to mass percentage, add to the reaction kettle, heat up to 80°C and stir for 120 minutes, Cool to 50°C, filter and discharge to obtain component A;

[0041] (3) Preparation of component B: mix methyltetrahydrophthalic anhydride, self-made flexible polyurethane, silicon micropowder, modified imidazole, BYK-W995, and phenothiazine according to the mass percentage, add it to a high-speed dispersion kettle, heat up to 50°C and stir 110min, filtering and discharging obtains B component;

[0042]Mix compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com