A kind of infrared reflective heat insulation coating and preparation method thereof

A heat-insulating coating and infrared reflection technology, applied in the direction of reflection/signal coating, coating, etc., to achieve the effect of improving reflectivity, fewer types of raw materials, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

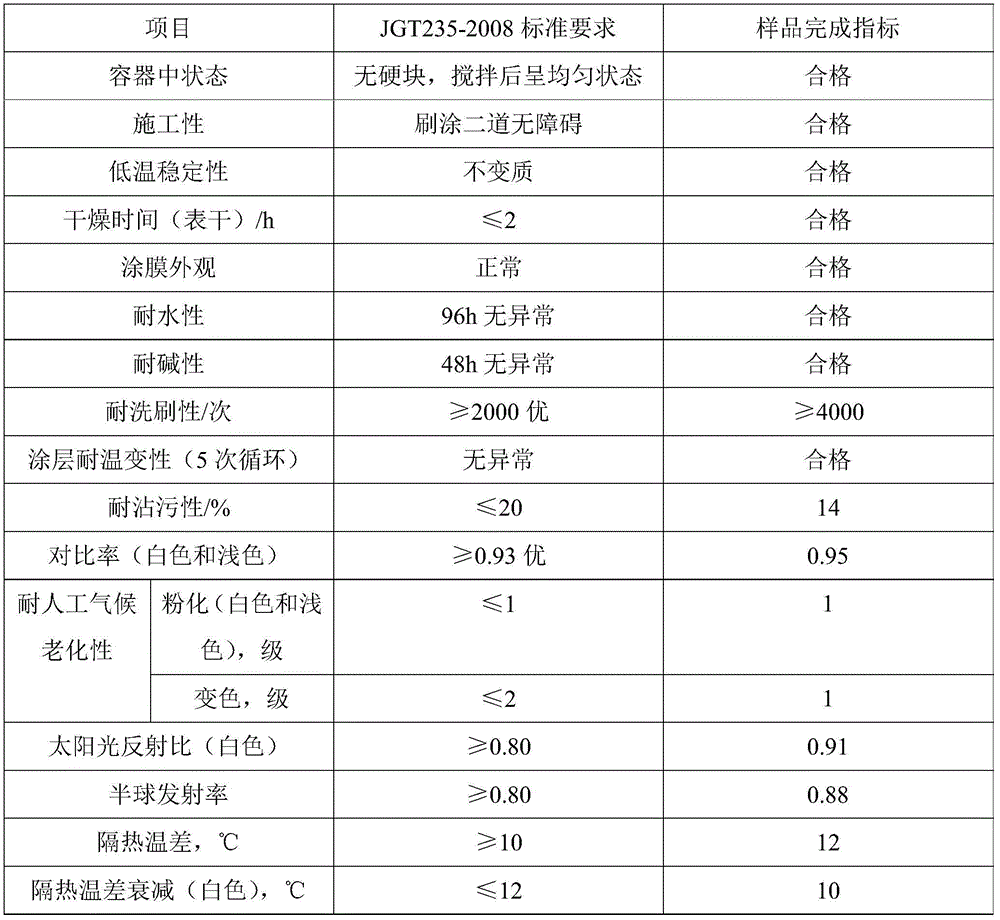

Examples

Embodiment 1

[0030] An infrared reflective heat-insulating coating, which contains the following raw material components by weight percentage: 60% of film-forming emulsion, 6% of rutile titanium dioxide, 2% of hollow glass microspheres (heat-insulating filler), surface stabilization treatment Hemihydrate gypsum whiskers 6%, propylene glycol (film-forming aid) 1.5%, simethicone (defoamer) 2%, polyvinyl alcohol (thickener) 0.5%, sodium hexametaphosphate (dispersant) 0.5%, water 21.5%. Wherein, the film-forming emulsion includes, by mass percentage: 5% styrene-acrylic emulsion, 0.5% silane coupling agent KH570, and 94.5% vinyl acetate-ethylene copolymer emulsion (commercially available VAE707 emulsion).

[0031] The preparation method of the above-mentioned infrared reflective heat-insulating coating comprises the following steps:

[0032] 1) According to the above ratio, add 6g of rutile titanium dioxide, 6g of hemihydrate gypsum whiskers, 0.5g of sodium hexametaphosphate (dispersant), and ...

Embodiment 2

[0036] An infrared reflective heat-insulating coating, which contains the following raw material components by weight percentage: 60% of film-forming emulsion, 6% of rutile titanium dioxide, 2% of hollow glass microspheres (heat-insulating filler), surface stabilization treatment Anhydrite whiskers 6%, propylene glycol (film-forming aid) 1.5%, sodium dodecylbenzenesulfonate (defoamer) 2%, polyvinyl alcohol (thickener) 0.5%, sodium hexametaphosphate (dispersant) 0.5%, water 21.5%. Wherein, the film-forming emulsion includes, by mass percentage: 10% of styrene-acrylic emulsion, 1% of silane coupling agent KH570, and 89% of vinyl acetate-ethylene copolymer emulsion (commercially available VAE707 emulsion).

[0037] The preparation method of the above-mentioned infrared reflective heat-insulating coating comprises the following steps:

[0038] 1) According to the above ratio, add 6g of rutile titanium dioxide, 6g of anhydrite whiskers, 0.5g of sodium hexametaphosphate (dispersant...

Embodiment 3

[0041] An infrared reflective heat-insulating coating, which contains the following raw material components by weight percentage: 50% of film-forming emulsion, 10% of rutile titanium dioxide, 3% of mica (heat-insulating filler), surface-stabilized hemihydrate Gypsum whiskers 10%, ethylene glycol (film-forming aid) 2%, sodium dodecylbenzenesulfonate (defoamer) 3%, hydroxyethyl cellulose (thickener) 1.5%, tripolyphosphoric acid Sodium (dispersant) 0.5%, water 20%. Wherein, the film-forming emulsion includes, by mass percentage: 15% of styrene-acrylic emulsion, 0.5% of silane coupling agent KH570, and 84.5% of vinyl acetate-ethylene copolymer emulsion (commercially available VAE707 emulsion).

[0042] The preparation method of the above-mentioned infrared reflective heat-insulating coating comprises the following steps:

[0043] 1) According to the above ratio, add 10g of rutile titanium dioxide, 10g of hemihydrate gypsum whiskers, 0.5g of sodium tripolyphosphate (dispersant), 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com