Novel method for converting industrial waste 1,2-dimethylhydrazine into methylhydrazine

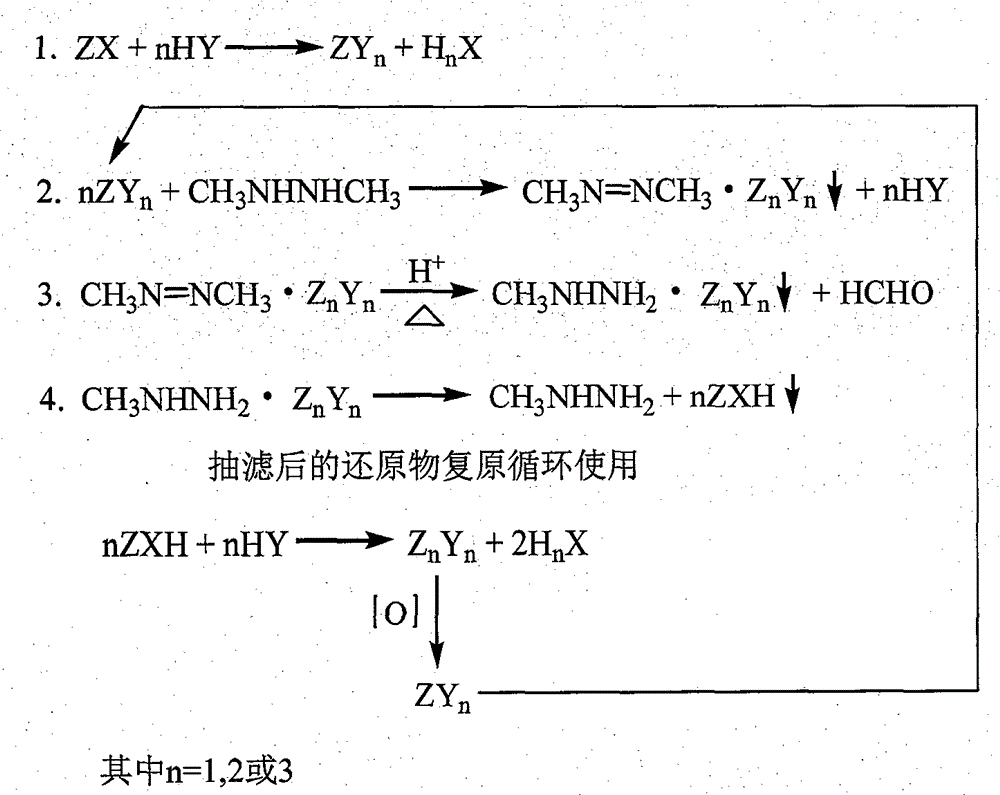

A technology of dimethyl hydrazine and industrial waste, applied in the directions of hydrazine preparation, organic chemistry, etc., can solve the problems of waste, environmental pollution and resources, and achieve the effects of low cost, high conversion rate, and avoiding environmental pollution and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add respectively 265g (22.7%) of waste liquid and 324g (2mol) of ferric trichloride containing 1mol1,2-dimethylhydrazine in the 2L four-necked round-bottomed flask that thermometer, stirrer and reflux condenser are equipped with and Stir continuously for a period of time, add 2mol of 45% phosphoric acid aqueous solution dropwise under ice-salt water cooling, heat to 5-95°C for 1-16 hours after dropping, add solid calcium oxide when the reaction solution is cooled to about 0-10°C with ice-salt water Adjust the pH value to between 5 and 13, filter the generated inorganic salts by means of suction filtration, wash the filter cake with cold water, combine the filtrate and washing liquid and rectify, collect 95g of components between 101 and 103°C, a The content of hydrazine is 43%, the recovery rate is 88%, and the purity is 98%.

Embodiment 2

[0024] In the 2L four-neck round-bottomed flask that thermometer, stirrer and reflux condenser tube are equipped with, add respectively the waste liquid of 265g (22.7%) containing 1mol1, the copper oxide powder of 2-dimethylhydrazine and 160g (2mol), in Add 2 mol of 95% sulfuric acid dropwise under ice-brine cooling, heat to 5-95°C and control the temperature for 1-16 hours after dropping, add ammonia water to adjust the pH value to 5-13 when the reaction solution is cooled to about 0-10°C with ice-brine In between, filter the generated inorganic salts by means of suction filtration, wash the filter cake with cold water, combine the filtrate and washing liquid and rectify, collect 98g of components between 101 and 103°C, and the content of monomethylhydrazine is 39%. , the recovery rate was 83%, and the purity was 98.5%.

Embodiment 3

[0026] In the 2L four-neck round bottom flask that thermometer, stirrer and reflux condenser are equipped with, add respectively the waste liquid of 265g (22.7%) containing 1mol1,2-dimethylhydrazine and the solid potassium chlorate of 245g (2mol), in ice Add 197g (2mol) of 37% hydrochloric acid dropwise under brine cooling, heat to 5-95°C and control the temperature for 1-16 hours after dropping, add solid potassium hydroxide to adjust the pH when the reaction solution is cooled to about 0-10°C with ice-brine When the value is between 5 and 13, filter the generated inorganic salts by suction filtration, wash the filter cake with cold water, combine the filtrate and washing liquid and rectify, collect 118g of components between 101 and 103°C, monomethylhydrazine The content is 31%, the recovery rate is 83%, and the purity is 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com