Compound probiotics as well as production process and application thereof to leavening agent

A technology of compound probiotics and production process, which is applied to multi-purpose probiotic starters. The application field of this composite probiotics on starters can solve the problems of expensive equipment, high cost, and high process requirements, so as to improve product quality and production Efficiency, solving safety problems, improving the effect of source safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

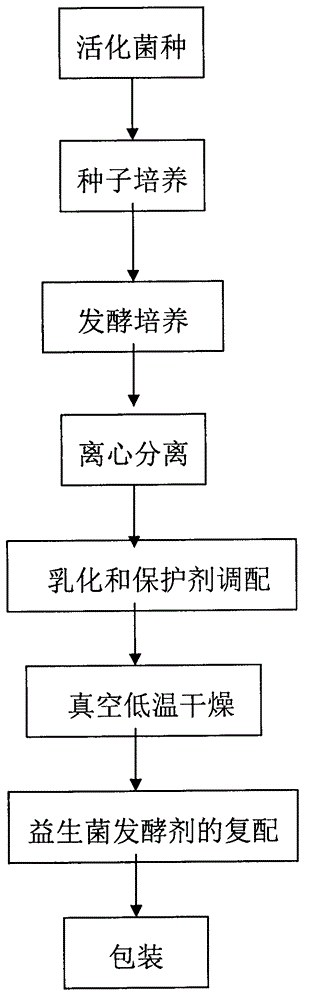

Method used

Image

Examples

example 1

[0075] Example 1: Production of compound probiotic powder

[0076] 1) activated bacterial classification: the bacterial classification that the present invention adopts is:

[0077] Lactobacillus plantarum, deposit number: CGMCC1.557

[0078] Lactobacillus fermentum, deposit number: CGMCC1.2133

[0079] Lactobacillus casei, deposit number: CICC20983

[0080] Lactobacillus rhamnosus LactobaciUus rhamnosus, preservation number: CICC20300

[0081] The above strains are purchased raw materials, and the ratio of the strains contained in them is: 6:2:1:1;

[0082] Activated strains were prepared as follows:

[0083] Insert the frozen-preserved bacteria into the sterilized MRS medium, and incubate at a constant temperature of 37°C for 24 hours. After confirming that the colonies are free of bacteria, repeat the operation three times to obtain the activated bacteria.

[0084] The MRS medium used above is: casein peptone 10.0, beef extract 10.0, yeast extract 5.0, glucose 5.0, sod...

Embodiment 2

[0112] Embodiment two: fermented pickles

[0113] Ingredients: radish, cowpea, salt, sucrose, spices.

[0114] 1. Wash 1 kg of radish and cut into pieces.

[0115] 2. Prepare 4% salt water in cold boiled water, add 1% sucrose, and stir to fully dissolve.

[0116] 3. Add 1 gram of probiotic starter into the above salt water and fully dissolve;

[0117] 4. Put the radish into the marinating container and add the seasoning together;

[0118] 5. Inject the brine of the prepared bacteria into the pickling container, and completely immerse the radish in the brine;

[0119] 6. Seal and ferment for 3 days at 30 degrees to mature.

[0120] The kimchi prepared by the process has strong flavor, crispy taste and rich nutrition. The final pH value is 3.8, and the smoked nitrate content is all below 0.5 mg / kg after testing, meeting the food safety requirements.

[0121] The above-mentioned radish can also be replaced by other vegetables, such as cabbage, cabbage, etc.

Embodiment 3

[0122] Embodiment 3: Fermentation Northeast sauerkraut

[0123] 1. Arrange the harvested vegetables to remove rotten leaves, wash them, cut them in half or quarters, and put them neatly into the fermentation tank;

[0124] 2. Prepare 4% brine and stir to fully dissolve;

[0125] 3. Add the probiotic starter into the above-mentioned brine, fully dissolve, and put in the starter at a ratio of 0.2 to 1 kg / ton;

[0126] 4. Inject the prepared brine of the bacteria into the pickling container, and completely immerse the vegetables in the brine;

[0127] 5. Start the conveying pump and return the brine to fully mix the brine in the pickling pool;

[0128] 6. Cover the mouth of the fermentation tank and ferment at room temperature.

[0129] Northeast sauerkraut is fermented with the above-mentioned process. The fermentation time is 15 days in winter and 7-8 days in summer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com