Special fertilizer for corn

A technology of special fertilizer and compound fertilizer for corn, applied in application, fertilization device, fertilizer mixture and other directions, can solve the problems of difficulty in directly acting on corn root system, low fertilizer utilization rate, low absorption efficiency, etc. Effects of soil improvement and stable supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

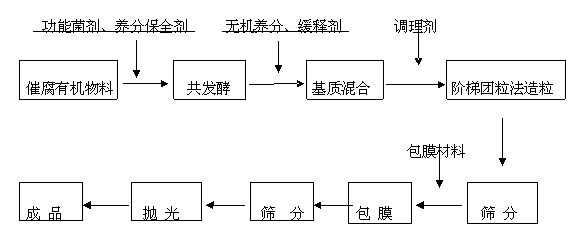

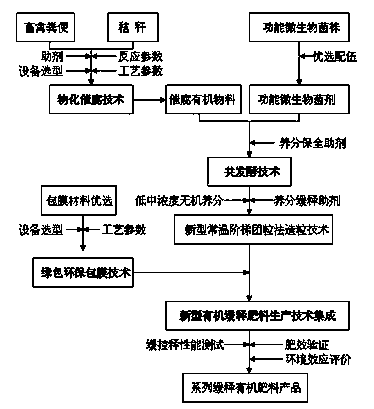

Method used

Image

Examples

Embodiment 1

[0026] According to the need to produce one ton of fertilizer: 235kg of urea, 105kg of monoammonium phosphate, 130kg of potassium chloride, 5kg of boron fertilizer, 10kg of zinc sulfate, 95kg of attapulgite, 35kg of decomposed stone powder, 250kg of fermented animal manure, and 135kg of peat.

[0027] Mix the above raw materials according to the formula and lift them into the multi-dimensional high-efficiency mixer for 5-10 minutes, and the fully mixed materials flow out to the pulverizer for crushing, and then make round spherical particles in the disc granulator; Drying, cooling, coating, screening machine, the particles are dried in the drying section at low temperature (≤100°C), and then enter the cooling section for air cooling, the air cooling temperature is controlled at 30°C, and the fully cooled materials enter the screening machine to be The powder and large particles are screened out, and then returned to the mixing and granulation system to coat the material; the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com