Instant-drying solvent-free adhesive for PVC (polyvinyl chloride) pipeline bonding

An adhesive and solvent-free technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor heat and humidity resistance, high brittleness, etc., and achieve good migration resistance, heat and humidity resistance, and adhesion The effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

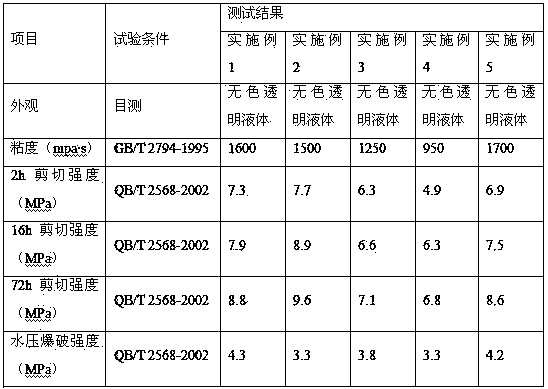

Examples

Embodiment 1

[0028] Embodiment 1 (by weight percentage):

[0029] Ethyl cyanoacrylate 83.85%

[0030] Chlorinated polyvinyl chloride resin 8%

[0031] Terminated vinyl nitrile rubber VTBNX 1300×43 1%

[0032] Polymethylmethacrylate 4%

[0033] Dioctyl phthalate 2%

[0034] Fumed silica 1%

[0035] Sulfur dioxide 0.05%

[0036] Hydroquinone 0.1%.

[0037] Weigh ethyl cyanoacrylate, chlorinated polyvinyl chloride resin, vinyl-terminated nitrile rubber VTBNX 1300×43, sulfur dioxide, and hydroquinone respectively according to the weight percentages listed in Example 1, and mechanically stir at 60° C. for 60 Minutes, the stirring rate is 800 rpm, then add polymethyl methacrylate, dioctyl phthalate, fumed silica, and continue stirring for 20 minutes, the stirring rate is 800 rpm, to obtain instant drying for PVC pipe bonding Solvent-free adhesive, cool to room temperature, and perform performance test after standing for 24 hours.

Embodiment 2

[0038] Embodiment 2 (by weight percentage):

[0039] Methyl cyanoacrylate 83.43%

[0040] Chlorinated polyvinyl chloride resin 7%

[0041] Terminated vinyl nitrile rubber VTBNX 1300×43 1%

[0042] Terminated vinyl nitrile rubber VTBNX 1300×33 0.5%

[0043] Polymethylmethacrylate 4%

[0044] Dioctyl phthalate 2%

[0045] Fumed silica 2%

[0047] Hydroquinone 0.05%.

[0048] Weigh methyl cyanoacrylate, chlorinated polyvinyl chloride resin, vinyl-terminated nitrile rubber VTBNX 1300×43, vinyl-terminated nitrile rubber VTBNX 1300×33, sulfur trioxide, respectively, according to the weight percentages listed in Example 2. , hydroquinone, stirred mechanically at 60°C for 60 minutes, and the stirring rate was 800 rpm, then added polymethyl methacrylate, dioctyl phthalate, fumed silica and continued to stir for 20 minutes, and the stirring rate was 800 rpm, the instant-dry solvent-free adhesive for PVC pipe bonding was obtained, cooled to room...

Embodiment 3

[0049] Embodiment 3 (by weight percentage):

[0050] Butyl cyanoacrylate 84.9%

[0051] Chlorinated polyvinyl chloride resin 5%

[0052] Terminated vinyl nitrile rubber VTBNX 1300×33 1%

[0053] Polymethylmethacrylate 3%

[0054] Polybutylmethacrylate 3%

[0055] Dioctyl phthalate 1.5%

[0056]Fumed silica 1.5%

[0057] Sulfur dioxide 0.02%

[0058] Hydroquinone 0.08%.

[0059] Weigh butyl cyanoacrylate, chlorinated polyvinyl chloride resin, vinyl-terminated nitrile rubber VTBNX 1300 × 33, sulfur dioxide, and hydroquinone respectively according to the weight percentages listed in Example 3, and mechanically stir at 60°C for 60 Minutes, the stirring rate is 800 rpm, then add polymethyl methacrylate, polybutyl methacrylate, dioctyl phthalate, fumed silica, continue to stir for 20 minutes, the stirring rate is 800 rpm, to obtain Instant dry solvent-free adhesive for PVC pipe bonding, cool to room temperature, and perform performance test after standing for 24 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com