Colorized GRC product prepared from multi-grading waste glass and preparation method thereof

A waste glass and color technology, applied in the field of building decoration materials, can solve the problems of chromatic aberration, affecting the decorative effect, fading, etc., to reduce costs, avoid fading and chromatic aberration, and achieve high economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] (1) Weigh 50 g of silicate glass powder and disperse it in 50 g of distilled water, add 0.025 g of sodium silicate suspending agent and 0.5 g of cobalt chloride colorant, mix the above powders and carry out mechanical ball milling for 12 h, and After the mixed slurry passes through a 400-mesh sieve, a glaze with stable suspension and uniform dispersion is obtained.

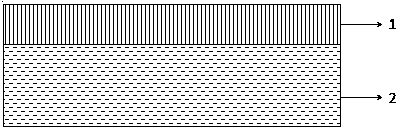

[0145] (2) The obtained glaze is sprayed to form a uniform glaze layer on the surface of the GRC substrate, and dried at 60°C for 30 minutes, and the dried GRC building material is preheated to 400°C, and heated with a flame The hydrogen-oxygen flame at a temperature of 1500 °C was evenly sprayed onto the surface of the GRC substrate, and the residence time was 10 s, so that the glaze layer was rapidly melted and combined with the GRC substrate, and an intermediate layer about 10 μm thick was obtained.

[0146] (3) Apply the glaze slurry obtained in step 1 evenly on the surface of the intermediate layer obt...

Embodiment 2

[0148] (1) Weigh 50 g of borosilicate glass powder and disperse it in 100 g of distilled water, add 0.05 g of polyvinyl alcohol and 1.0 g of ferric chloride, mix the above powders and perform mechanical ball milling for 24 h, and pass the mixed slurry After a 600-mesh sieve, a glaze with stable suspension and uniform dispersion is obtained.

[0149] (2) Form a uniform glaze layer on the surface of the GRC substrate by brushing the obtained glaze, and dry it at 80 °C for 30 min, preheat the dried GRC building material to 500 °C, and The acetylene oxygen flame with a flame temperature of 2000 °C was evenly sprayed onto the surface of the GRC substrate, and the residence time was 5 s, so that the glaze was rapidly melted and combined with the GRC substrate, and an intermediate layer about 20 μm thick was obtained.

[0150] (3) Apply the glaze slurry obtained in step 1 evenly on the surface of the intermediate layer obtained in step 2 by brushing to form a glaze layer, and dry at ...

Embodiment 3

[0152] (1) Weigh 50 g of lead silicate glass powder and disperse it in 25 g of distilled water, add 0.1 g of gum arabic suspending agent and 2.5 g of copper oxide colorant, mix the above powders and carry out mechanical ball milling for 48 h, and put After the mixed slurry is passed through a 200-mesh sieve, a glaze with stable suspension and uniform dispersion is obtained.

[0153] (2) Form a uniform layer of glaze on the surface of the GRC substrate by glazing the obtained glaze, and dry it at 70 °C for 40 min, preheat the dried GRC building material to 300 °C, heat The silicon carbide rod at a temperature of 1000oC heats the glaze on the surface of the GRC substrate for a residence time of 7 s, so that the glaze melts quickly and combines with the GRC substrate to obtain an intermediate layer with a thickness of about 30 μm.

[0154] (3) Apply the glaze slurry obtained in step 1 evenly on the surface of the intermediate layer obtained in step 2 to form a glaze layer by glaz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com