Treatment method for paraquat pesticide wastewater

A technology for pesticide wastewater and a treatment method, which is applied in the field of paraquat pesticide wastewater treatment, can solve the problems of long reaction time, high equipment requirements, and high operational danger, and achieves the effects of saving treatment costs, simple operation, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

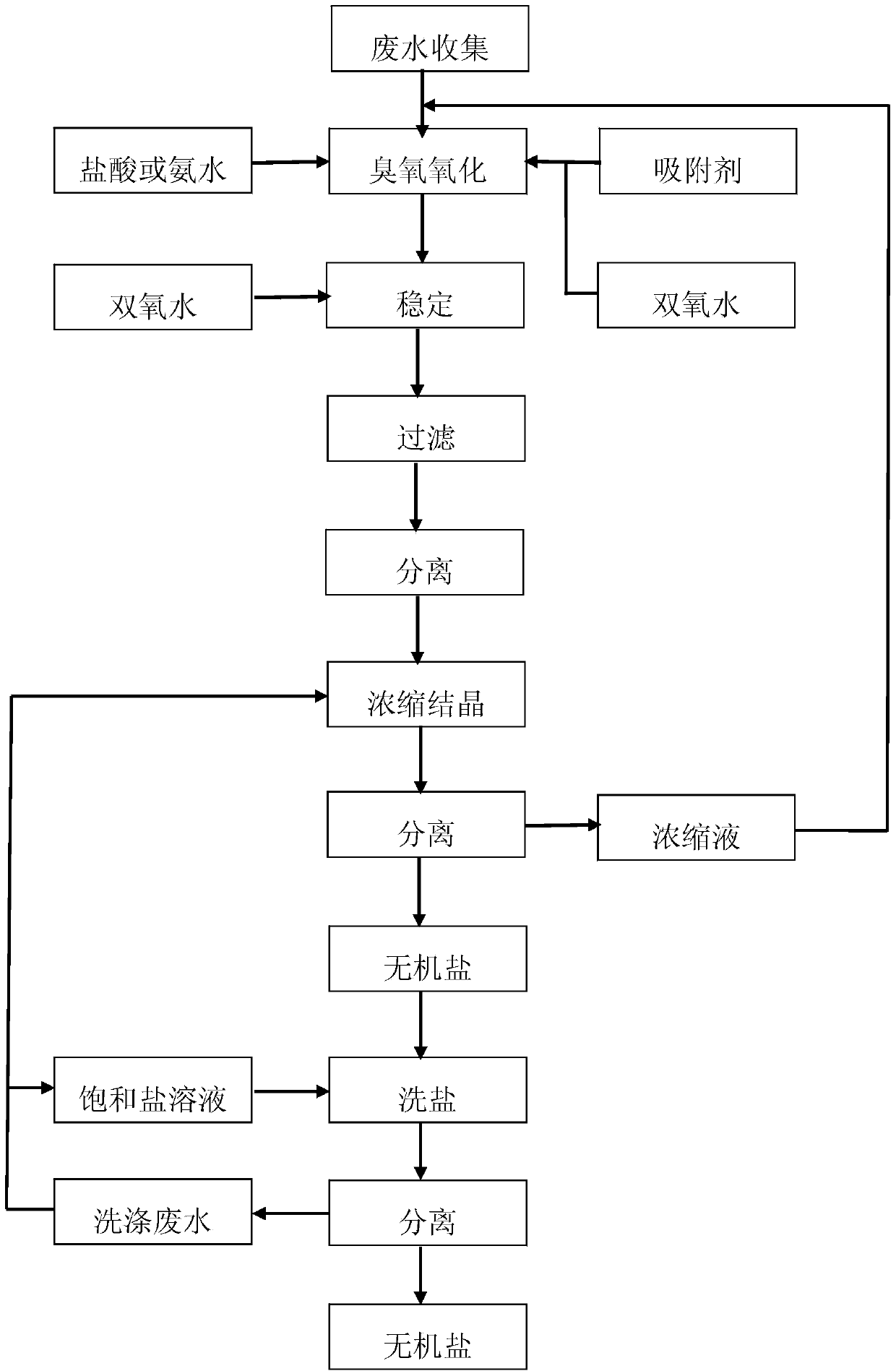

Method used

Image

Examples

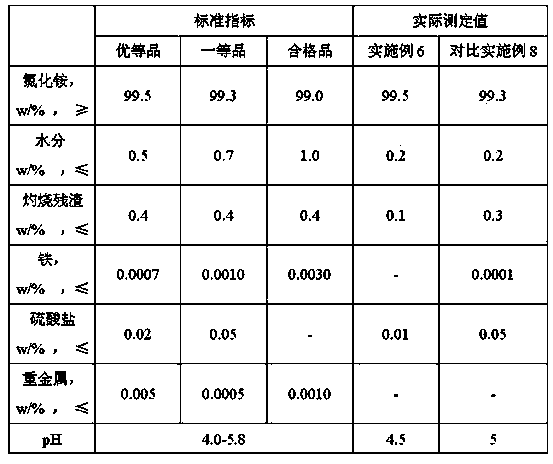

Embodiment 1

[0023] Paraquat pesticide wastewater (COD=65200 mg / L, NH3-N content is 89930 mg / L, CN - content=1100 mg / L, pH=10-12), add hydrochloric acid with a mass concentration of 36-38% to adjust the pH to 10, add 5% activated carbon of the wastewater mass, and after 2 hours of ozone oxidation reaction, add 10% of the wastewater mass Hydrogen peroxide (mass concentration: 50%), continue to oxidize for 6 hours. During the reaction process, the pH was adjusted online to stabilize the pH of the system at about 9. Immediately add 2% hydrogen peroxide (mass concentration: 30%) to the wastewater after oxidation and stir and mix for 0.5 hours. The filtrate obtained by filtering is clear light orange red, and the filtrate COD removal rate is about 75%. Concentrate and crystallize the filtrate to obtain a slightly yellowish salt, wash it once with 20% saturated washing liquid, and obtain qualified industrial salt. The concentrated condensate is clear and transparent, with COD=80 mg / L and amm...

Embodiment 2

[0025] In this example, paraquat wastewater (COD=65200 mg / L, NH3-N content is 89930 mg / L, CN - Content = 1100mg / L, pH = 10-12) add hydrochloric acid (36-38%wt) to adjust the pH to about 5, add diatomaceous earth with 5% of the wastewater quality, and the rest of the treatment methods are the same as in Example 1. The wastewater after the oxidation treatment is filtered to obtain a clear reddish-brown filtrate, and the filtrate COD removal rate is 57%; the filtrate is concentrated and crystallized to obtain dark red salt, which is washed twice with 30% saturated solution to obtain qualified industrial salt; The concentrated condensate is clear and slightly red, with COD=340 mg / L and ammonia nitrogen less than 35 mg / L.

Embodiment 3

[0027] In this example, paraquat wastewater (COD=65200 mg / L, NH3-N content is 89930 mg / L, CN - Content = 1100mg / L, pH = 10-12) add hydrochloric acid (36-38%wt) to adjust the pH to about 7, add 0.1% activated carbon of the wastewater quality, and the remaining treatment methods are the same as in Example 1. After the oxidation, the waste water was filtered to obtain a clear black-red filtrate, and the filtrate COD removal rate was 66%. The filtrate was concentrated and crystallized to obtain gray-red salt, which was washed twice with 40% saturated solution to obtain qualified industrial salt. The condensate obtained by concentration is clear and slightly yellow, with COD=80 mg / L and ammonia nitrogen about 100 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com