Carbon-coated nano-antimony composite material as well as preparation method and application thereof

A technology of composite materials and carbon coating, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of reduced uniformity of materials, difficulty in synthesis and control of carbon coating uniformity, and achieves The effect of low equipment requirements, low price, and wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

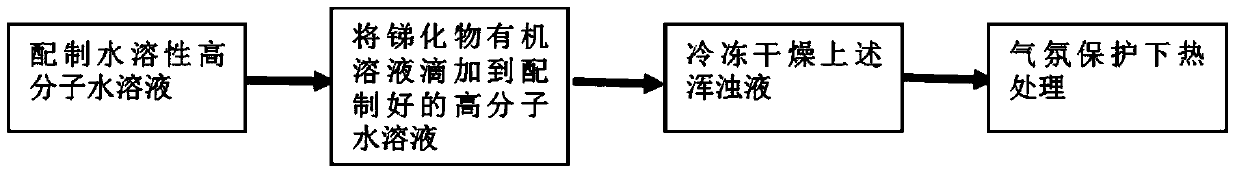

[0040] The specific process of preparing carbon-coated nano-antimony composite material in this embodiment is as follows:

[0041] The chitosan water-soluble polymer is dissolved in water to form an aqueous solution with a concentration of preferably 0.1 g / ml.

[0042] Slowly add antimony trichloride ethanol solution with a concentration of preferably 0.2 mol / L to the chitosan aqueous solution, so that the mass ratio of chitosan macromolecule to antimony chloride is 0.8.

[0043] After magnetic stirring for 24 h, the turbid solution was freeze-dried for 48 h.

[0044] The freeze-dried precursor was placed in Ar / 5%wtH 2 atmosphere, sintering at 750°C for 6 hours, and the carbon-coated nano-antimony composite material can be prepared.

[0045] Such as figure 1 As shown, it is a transmission electron microscope schematic diagram of the prepared carbon-coated nano-antimony composite material. In this example, the proportion of polymer carbon source is relatively small, and the ...

Embodiment 2

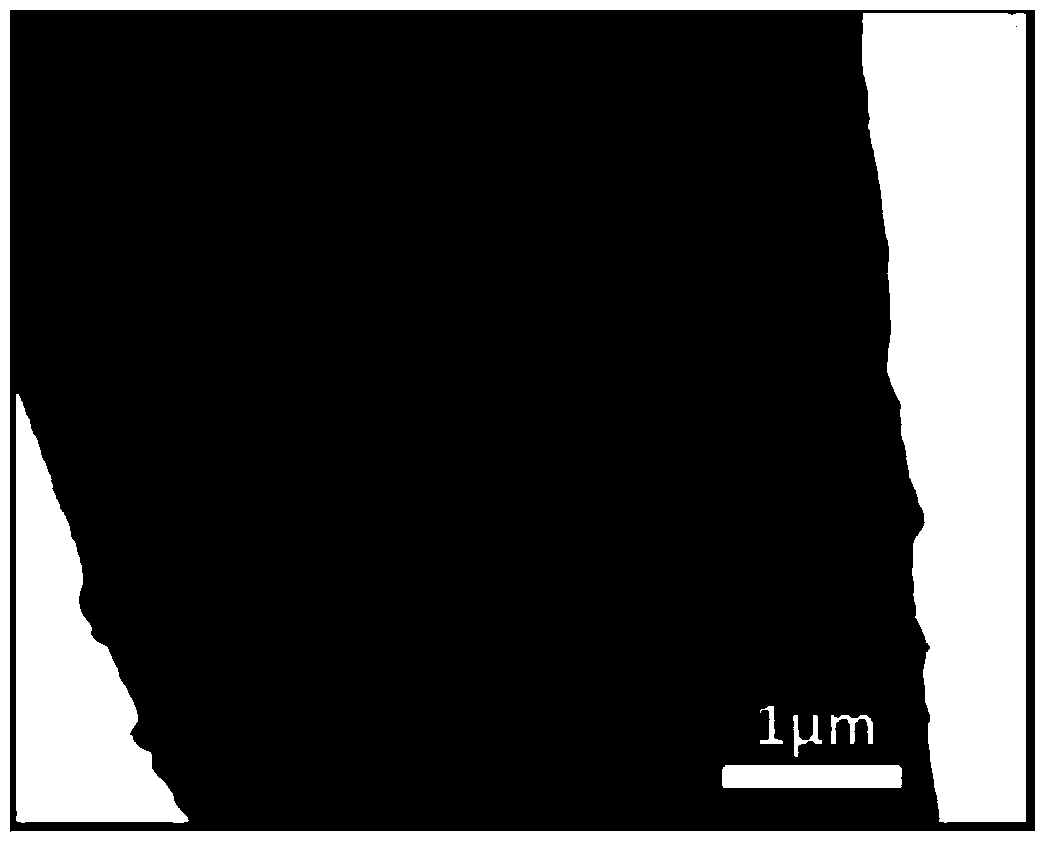

[0048] The chitosan water-soluble polymer is dissolved in water to form an aqueous solution with a concentration of 0.01 g / ml.

[0049] Slowly add antimony trichloride ethanol solution with a concentration of 0.05 mol / L to the chitosan aqueous solution, so that the mass ratio of chitosan macromolecule to antimony chloride is 2.

[0050] After magnetic stirring for 12 h, the cloudy solution was freeze-dried for 24 h.

[0051]The freeze-dried precursor was placed in Ar / 5%wtH 2 atmosphere, sintering at 650°C for 3 hours, and the carbon-coated nano-antimony composite material can be prepared.

[0052] Such as figure 2 As shown, it is a transmission electron microscope schematic diagram of the prepared carbon-coated nano-antimony composite material. Compared with Example 1, the polymer carbon source added in this example is relatively high, and the average particle size of the synthesized material is 50nm. Smaller than Example 1, the particles are evenly distributed in the carb...

Embodiment 3

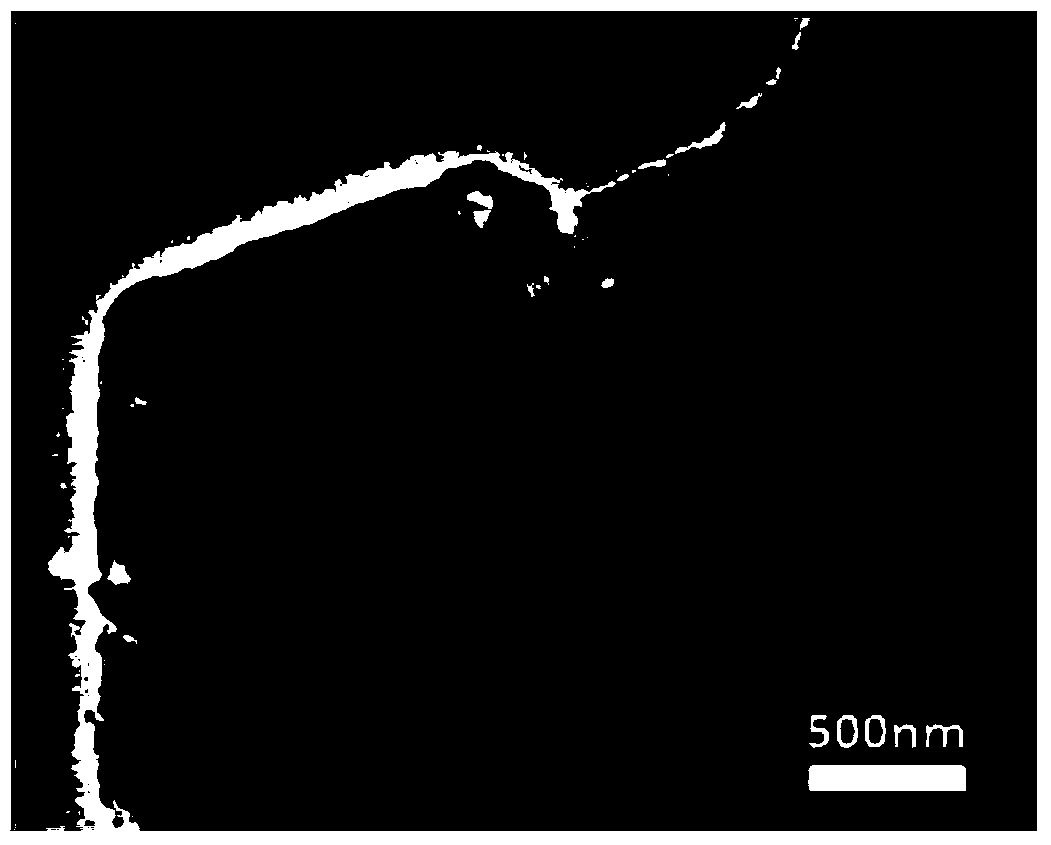

[0055] The chitosan water-soluble polymer is dissolved in water to form an aqueous solution with a concentration of 0.005 g / ml.

[0056] The antimony trichloride ethanol solution with a concentration of 0.01 mol / L is slowly added to the chitosan aqueous solution, so that the mass ratio of the chitosan polymer to the antimony chloride is 1.

[0057] After magnetic stirring for 6 h, the turbid solution was freeze-dried for 36 h.

[0058] The freeze-dried precursor was placed in Ar / 5%wtH 2 atmosphere, sintering at 450°C for 10 hours, the carbon-coated nano-antimony composite material can be prepared.

[0059] Such as image 3 As shown, it is a transmission electron microscope schematic diagram of the prepared carbon-coated nano-antimony composite material. In this embodiment, the carbon source addition ratio and solution concentration are better, and the average particle diameter of the synthetic material is 10nm, which is more than that of Examples 1 and 2. finer and more eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com