A method for improving the quality of fruit juice freezing and concentration assisted by variable voltage direct current electric field

A freeze concentration, DC electric field technology, applied in food science and other directions, can solve the problems of increasing the complexity of the process flow, low solute movement speed, loss of nutrients, etc., to increase the content of soluble solids, avoid solute entrainment in gaps, and ensure nutrition. the preserved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

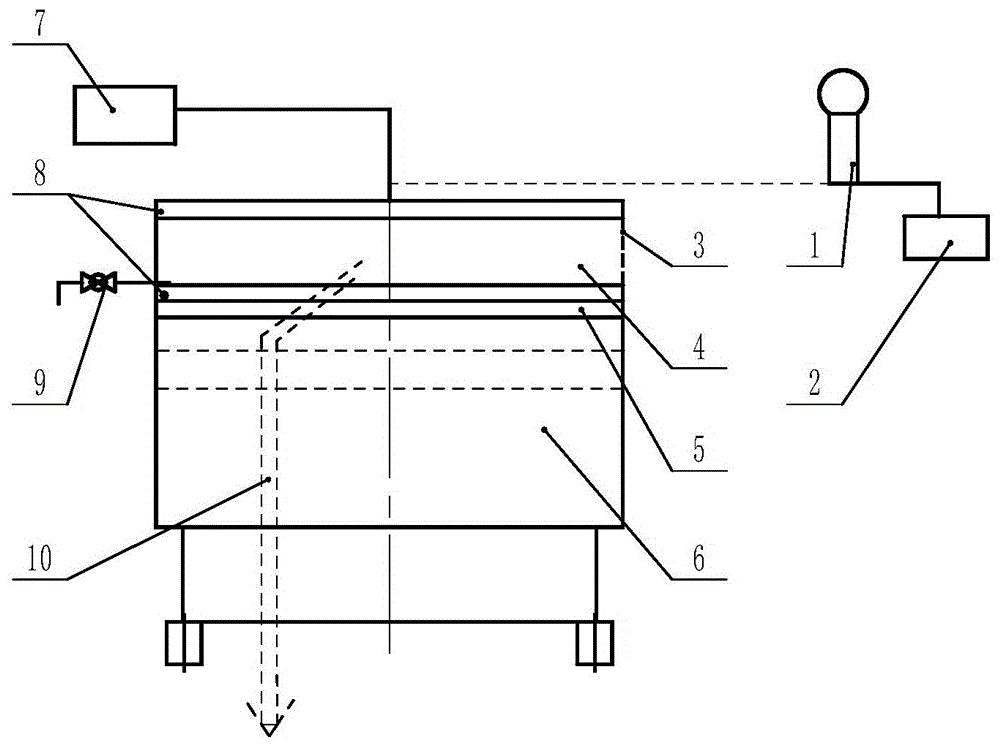

[0035] figure 1 It is a schematic diagram of the high static voltage semiconductor freezing treatment device used in this embodiment. Such as figure 1 As shown, it includes high-voltage generator 1, control electric box 2, optical fiber thermocouple position hole 3, freeze concentration sample tank 4, semiconductor refrigeration device 5, water tank 6, control electric box sample container 7, copper plate electrode 8, valve 9 and internal looking glass10. The copper plate electrode has two pieces that are symmetrical up and down. After the power is turned on, there is a uniform electric field system in the sample tank; the fiber optic thermocouple is used to measure the temperature change of the sample liquid, that is, to judge the nucleation time; the semiconductor is used to reduce the temperature of the sample tank, and the condensation cycle equipment is also Other cooling materials can be used; the endoscope is used to judge the internal icing condition, that is, to ass...

Embodiment 2

[0039] The method for improving the frozen and concentrated quality of fruit juice assisted by the variable voltage direct current electric field of the present embodiment comprises the following steps:

[0040] The papaya is taken from a commercial orchard in Maoming, Guangdong, with a maturity of 80% to 90%. After picking, refrigerate them in foam boxes, and transport them to the laboratory within 6 hours. Fruits with uniform size, shape, and color are strictly selected for the fruit juice freezing and concentration experiment. After the papaya is washed and cut into pieces, it is directly homogenized with a colloid mill, and then filtered with a fruit juice filter to obtain the original juice with a solid content of 8.0 ° brix, and placed in a 1 ° C refrigerator for pre-cooling. Turn on the semiconductor condensation cycle equipment, set the temperature to 1°C, after the set temperature is reached and the balance is stable, take 10L of pre-cooled papaya juice and place it i...

Embodiment 3

[0042] The red orange is taken from a commercial orchard in Zhanjiang, Guangdong, with a maturity of 80% to 90%. After picking, refrigerate them in foam boxes, and transport them to the laboratory within 6 hours. Fruits with uniform size, shape, and color are strictly selected for the fruit juice freezing and concentration experiment. After the oranges were peeled and cut into pieces, they were directly homogenized with a colloid mill, and then directly filtered with a juice filter to obtain the original juice with a solid content of 13.0°brix, and placed in a 2°C refrigerator for pre-cooling. Turn on the semiconductor condensation cycle equipment and set the temperature to 2°C. After the set temperature is reached and the balance is stable, take 10L of pre-cooled red orange juice and place it in the sample tank, and place the fiber optic thermocouple in the middle of the sample solution on the lower side and At the high position (about 1 / 5-1 / 4), turn on the endoscope at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com