Photocatalyst for degrading formaldehyde based on complexing stable dispersion, and preparation method and application thereof

A photocatalyst and complexing technology, applied in the field of photocatalyst, can solve the problems of low film-forming adhesion, agglomeration and precipitation, and low dispersion level, and achieve the effects of improving adhesion and uniformity, mild preparation conditions and stable dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

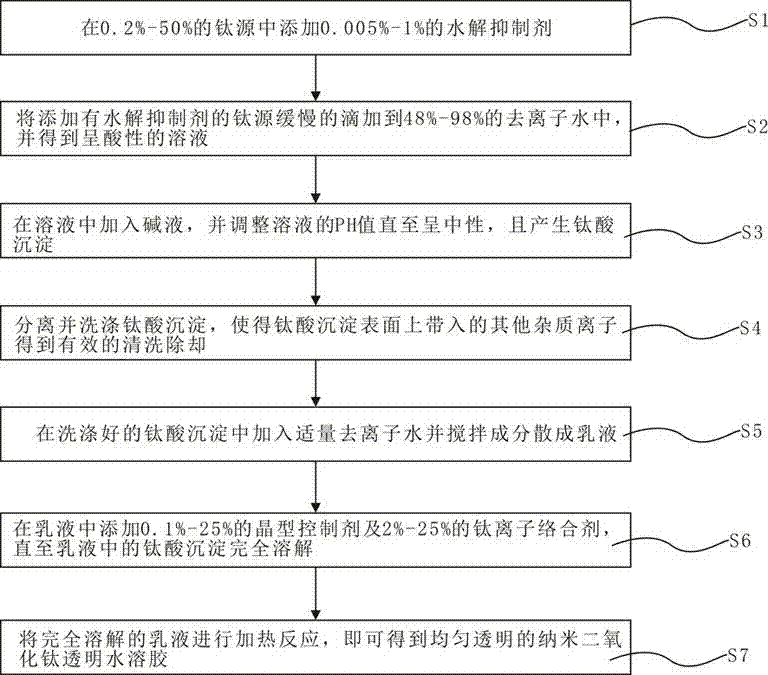

[0048] see figure 1 , the preparation method of the photocatalyst that is used for degrading formaldehyde based on the stable dispersion of complexation provided by the invention, comprises the following steps:

[0049] Step S1, adding 0.005%-1% hydrolysis inhibitor to 0.2%-50% titanium source; the titanium source in this step is butyl titanate, titanium tetrachloride, titanium trichloride or ethyl titanate Any one of them may also be tetraisopropanone titanate, etc.; the hydrolysis inhibitor is any one of glacial esters, acetylacetone, and concentrated hydrochloric acid.

[0050] Step S2, slowly drop the titanium source added with a hydrolysis inhibitor into 48%-98% deionized water to obtain an acidic solution; the conductivity of the deionized water is less than or equal to 1-1.5μS / cm .

[0051] Step S3, adding lye to the solution, and adjusting the pH value of the solution until it is neutral, and the neutralization reaction produces titanic acid precipitation; the lye is...

experiment example 1

[0063] 1. Experimental method:

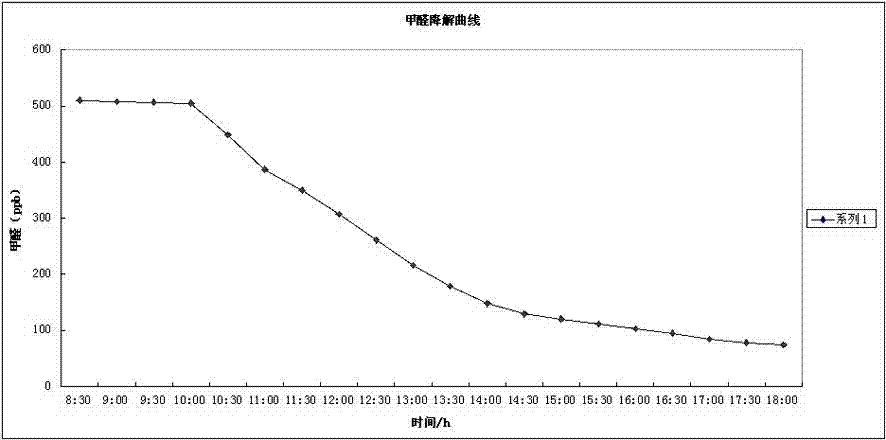

[0064] 1. Spray a certain amount of nano-titanium dioxide transparent hydrosol sample with a concentration of 0.5% on a glass plate of 1 square meter, place it in a glass experimental chamber of 1.5 cubic meters, and fill it with a certain amount of standard concentration of formaldehyde gas under darkroom conditions , and start the air circulation pump in the warehouse, and stop filling the formaldehyde standard gas when the formaldehyde concentration in the warehouse is stable at 510ppb. After the dark adsorption equilibrium (the process time is generally 0.5-1h, when the gas concentration in the warehouse changes less than 10ppb / h, it is regarded as the dark adsorption equilibrium), and the internal formaldehyde concentration is measured three times within the next 1.5h, and recorded. After the test, turn on the fluorescent lamp (wavelength range 400-800nm) in the warehouse to irradiate, and record the formaldehyde concentration in the chamb...

experiment example 2

[0072] 1. Experimental method:

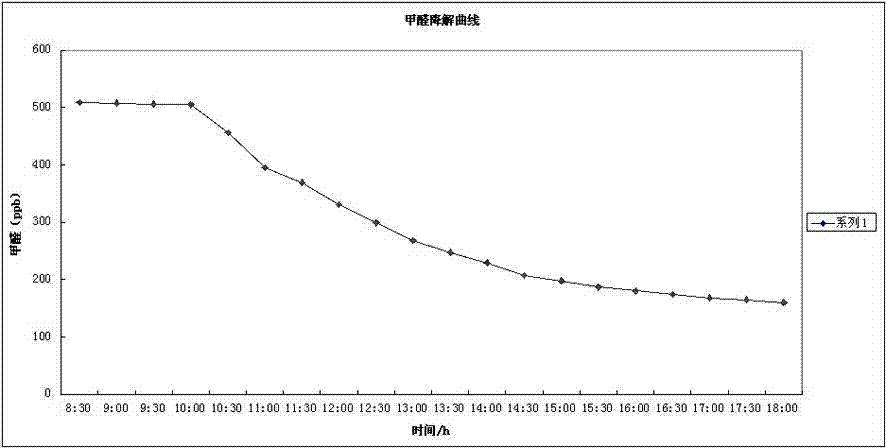

[0073] 1. Spray a certain amount of nano-titanium dioxide transparent hydrosol sample with a concentration of 0.2% on a glass plate of 1 square meter, place it in a glass experimental chamber of 1.5 cubic meters, and fill it with a certain amount of standard concentration of formaldehyde gas under darkroom conditions , and start the air circulation pump in the warehouse, and stop filling the formaldehyde standard gas when the formaldehyde concentration in the warehouse is stable at 510ppb. After the dark adsorption equilibrium (the process time is generally 0.5-1h, when the gas concentration in the warehouse changes less than 10ppb / h, it is regarded as the dark adsorption equilibrium), and the internal formaldehyde concentration is measured three times within the next 1.5h, and recorded. After the test, turn on the fluorescent lamp (wavelength range 400-800nm) in the warehouse for irradiation. Record the formaldehyde concentration in the box e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com