Poly-o-phenylenediamine nanometer metal composite particle and preparation method

A poly-o-phenylenediamine and nano-metal technology, applied in the direction of coating, etc., to achieve the effect of simple preparation method, high reproducibility, and short experimental cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

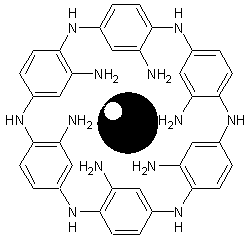

Image

Examples

preparation example Construction

[0031] 聚邻苯二胺-纳米金属复合颗粒的制备方法的步骤如下:

[0032] 1)在冰浴环境下,将0.002-0.006 mol金属硝酸盐溶解于20-80mL 质量百分比浓度为2%-8%的分散-稳定剂溶液中,使用机械搅拌使上述混合液发泡,发泡量为分散-稳定剂溶液体积的5倍,取0.001-0.005 mol还原剂溶解于冰水,待溶解完全后将还原剂溶液逐滴滴入金属硝酸盐-分散剂溶液中,使反应液中的金属离子完全转变为金属单质;

[0033] 2)上述反应完全后,将步骤1)中的反应液加入离心管,在2000 r / min转速下进行离心分离2-4 min,将所得胶体金属稀释100倍后作紫外分析,验证纳米金属颗粒 Synthesis;

[0034] 3)取0.0005-0.0015 mol邻苯二胺加入至1mol / L的盐酸溶液中,超声处理使其完全溶解,取等体积的邻苯二胺盐酸溶液与胶体金属混合,搅拌12小时使邻苯二胺上的氨基与纳米金属颗粒结合并分散均匀;

[0035] 4)将氧化剂溶于水,然后在冰浴条件下,将氧化剂溶液逐滴滴加至步骤3)所得到的溶液,搅拌使其反应18-24个小时;

[0036] 5)脱水后淋洗,得到聚邻苯二胺-纳米金属复合颗粒。

[0037] 所述的金属硝酸盐是硝酸铜、硝酸银或硝酸铋。所述的分散-稳定剂是聚乙烯醇,聚乙二醇或聚乙烯吡咯烷酮中的一种或数种。所述的还原剂是硼氢化钠,所述的氧化剂是过硫酸铵。所述的脱水是离心脱水、压滤脱水或抽滤脱水。所述的胶体金属的分散剂是质量百分比浓度为2-8%的分散剂水溶液20-80mL。

[0038] 本发明的纳米金属颗粒及其尺寸通过紫外-可见分光光度计(uv-vis)及透射电子显微镜(TEM)证实,本发明的聚邻苯二胺-纳米金属颗粒核壳结构通过透射电子显微镜(TEM)及能量色散X射线光谱仪(EDX)证实。

Embodiment 1

[0040] 1)在冰浴环境下,将0.002mol硝酸铜溶解于20mL 8%的聚乙烯醇溶液中。使用强机械搅拌使上述混合液发泡,发泡量为聚乙烯醇分散-稳定剂溶液体积的5倍。取0.001mol硼氢化钠溶解于冰水。待溶解完全后将硼氢化钠溶液逐滴滴入硝酸铜-聚乙烯醇溶液中,使反应液中的铜离子完全转变为铜单质。

[0041] 2)上述反应完全后,将步骤1)中的反应液加入至离心管,在2000 r / min转速下进行离心分离2 min,将所得胶体金属稀释100倍后作紫外分析,验证纳米铜颗粒的 synthesis;

[0042] 3)取0.0005 mol邻苯二胺加入至1mol / L的盐酸溶液中,超声处理使其完全溶解,取等体积的邻苯二胺盐酸溶液与胶体金属混合,搅拌12小时使邻苯二胺上的氨基与纳米铜颗粒结合并分散均匀;

[0043] 4)将过硫酸铵溶于水,然后在冰浴条件下,将过硫酸铵溶液逐滴滴加至3)所得到的溶液。搅拌使其反应18个小时;

[0044] 5)脱水后淋洗,得到聚邻苯二胺-纳米铜复合颗粒。

Embodiment 2

[0046]1) Dissolve 0.004 mol silver nitrate in 40mL 4% polyethylene glycol solution in an ice bath environment. Use strong mechanical stirring to make the above mixed solution foam, and the foaming amount is 5 times the volume of the polyethylene glycol dispersion-stabilizer solution. Take 0.001 mol sodium borohydride dissolved in ice water. After the dissolution is complete, the sodium borohydride solution is dropped dropwise into the silver nitrate-polyethylene glycol solution, so that the silver ions in the reaction solution are completely converted into simple silver.

[0047] 2) After the above reaction is complete, add the reaction solution in step 1) to the centrifuge tube, and perform centrifugation at 2000 r / min for 3 minutes, dilute the obtained colloidal metal 100 times, and then conduct ultraviolet analysis to verify the concentration of silver nanoparticles. synthesis;

[0048] 3) Take 0.001mol o-phenylenediamine and add it to 1mol / L hydrochloric acid solution, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com