Catalyst for oxidizing and eliminating formaldehyde at room temperature and preparation method thereof

A technology for eliminating formaldehyde and a catalyst, which is applied in the field of catalysts and preparations for eliminating formaldehyde by oxidation at room temperature. It can solve the problems of difficult wide-scale application, poor catalyst durability, and high precious metal content, and achieve easy promotion and use, high elimination rate, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1-impregnation method prepares catalyst

[0038] Take a certain amount of precious metal precursor chloroplatinic acid and soluble carrier precursor ferric nitrate in proportion to dissolve in water, disperse 500g of insoluble carrier precursor aluminum oxide powder in the above aqueous solution, and use the auxiliary agent precursor sodium carbonate to adjust the pH value to 8.0, placed in an 80-degree water bath and stirred for 2 hours, then dried in a 100-degree oven for 2 hours, and then roasted for 2 hours under a nitrogen atmosphere at 300 degrees to obtain the desired catalyst.

[0039] It has been determined that the loading of the platinum component is 0.03% based on the conversion of the mass of the metal element. In the finally formed catalyst, the carrier is a composite of ferrous oxide and aluminum sesquioxide, and the additive component is sodium oxide.

Embodiment 2-10

[0040] Embodiment 2-10-preparation of catalyst by impregnation method

[0041] Using the same preparation process as in Example 1, only changing the type of precious metal precursor, the type of soluble carrier precursor, the type of insoluble carrier precursor, the type of auxiliary agent precursor, pH value, water bath time and water bath temperature, drying temperature and drying temperature , calcination time and calcination temperature, the impregnation method is used to prepare the catalyst, and the references for each reaction are shown in Table 1 and Table 2, and the detection parameters of the prepared catalyst are also shown in Table 1 and Table 2.

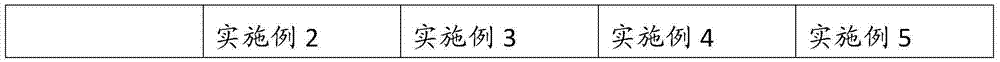

[0042] The reaction conditions and the result of table 1 embodiment 2-5

[0043]

[0044]

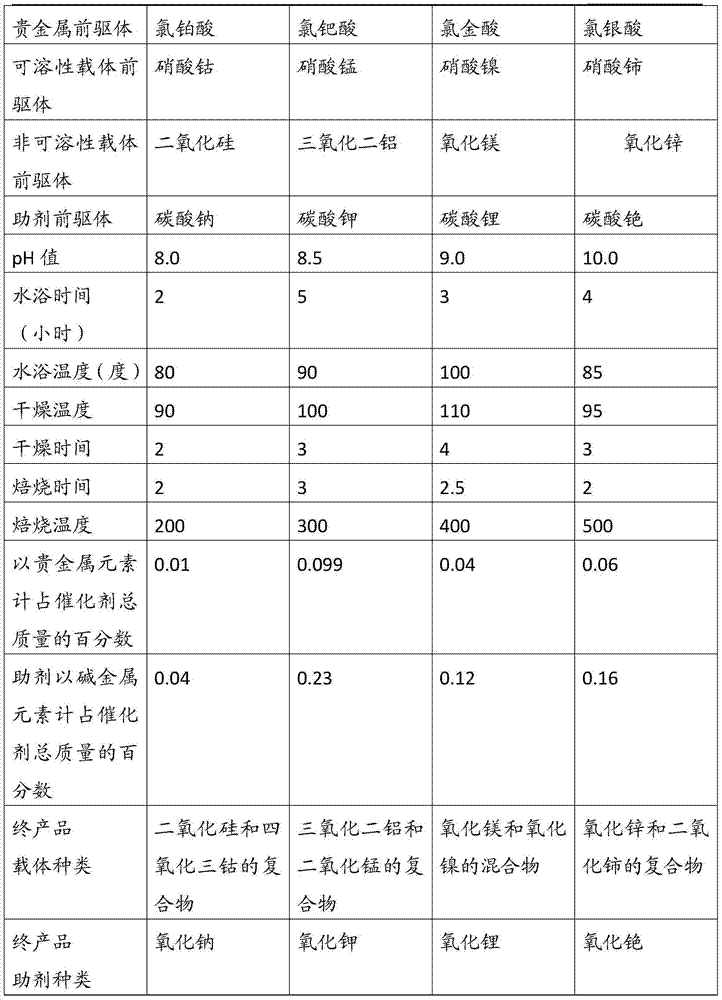

[0045] The reaction conditions and the result of table 2 embodiment 6-10

[0046]

[0047]

Embodiment 11-15

[0048] Embodiment 11-15---co-precipitation method prepares catalyst

[0049] Preparation Process:

[0050] S2.1, dissolving the selected noble metal active components, additive components and precursor soluble inorganic salts of carrier oxides in quantitative water according to a selected ratio to obtain a clear solution;

[0051] S2.2, adjust the pH of the solution obtained in S2.1, and adjust the pH to 8-12. After the precipitation is complete, filter and wash, take the filter cake and dry it in an oven at 100-150 degrees for 4-6 hours to obtain a semi-finished catalyst;

[0052] S2.3, put the catalyst semi-finished product obtained in S2.2 in a muffle furnace, and roast it in an air, nitrogen or argon atmosphere for 5-10 hours at a roasting temperature of 200-500 degrees to obtain a finished catalyst

[0053] In the above-mentioned preparation process, only the following relevant parameters are specifically limited for preparation. Refer to Table 3 for each reaction conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com