Preparation method of dutasteride

A technology of dutasteride and androsteride, applied in the field of medicine, can solve the problems such as difficult removal of impurities, unfavorable control, side reactions, etc., achieves guaranteed yield, avoids the generation of dutasteride by-products, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 The investigation of compound III refining and washing solvent

[0038] The inventors used different solvents to refine and wash the industrial-grade compound III, and the results are shown in Table 1. As can be seen from Table 1, the use of formic acid to wash compound III with acetone after beating at room temperature can effectively remove the residual alcohol reagent in the starting material, making the residual alcohol reagent ≤ 0.1%, and also avoiding the compound III. The addition reaction of ethylenic bonds produces new impurities, which can effectively control the product quality of dutasteride.

[0039] Table 1 Effect of different refining and washing solvents on dutasteride

[0040] Preface

[0041] No

[0042] Remarks: The detection of related impurities is carried out in the raw material drug dutasteride after positioning with the EP system applicability reference substance.

Embodiment 2

[0043] Example 2 The purification of industrial-grade compound III

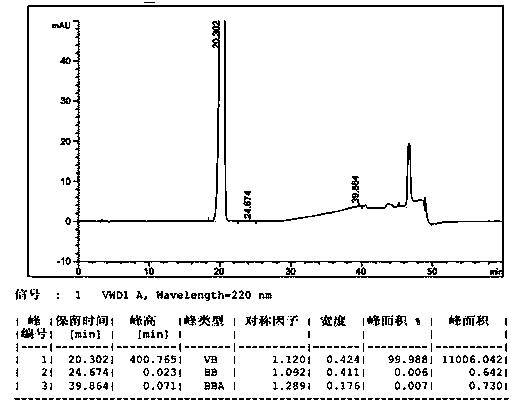

[0044] In a 3L reaction flask, add 500g of industrial grade compound III and 1.5L of anhydrous formic acid, stir and beat at 30-35°C for 5h, filter, and wash the filter cake with acetone, 0.5L each time, for a total of 2 washes, the solid is at 30-35 ℃ air-dried for 24 hours to obtain 375.0 g of the refined product of compound III, with a yield of 75.0% and a purity of 99.99%. The HPLC spectrum of its related substances is as follows: figure 1 shown.

Embodiment 3

[0045] Example 3 Refining of Industrial Grade Compound III

[0046] Into a 3L reaction flask, add 500g of industrial grade compound III and 1.2L of anhydrous formic acid, stir and beat at 30-35°C for 4 hours, filter, and wash the filter cake with acetone, 0.5L each time, for a total of 2 washes, the solid is at 30-35 ℃ blast drying for 20 h to obtain 373.6 g of compound III refined product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com