Layered silicate modified organosilicon grafted polyether polyurethane elastomer, preparation method and application

A polyurethane elastomer and layered silicate technology, applied in the field of polymer materials, can solve the problems of reduced tensile strength and toughness of silicone-modified polyurethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

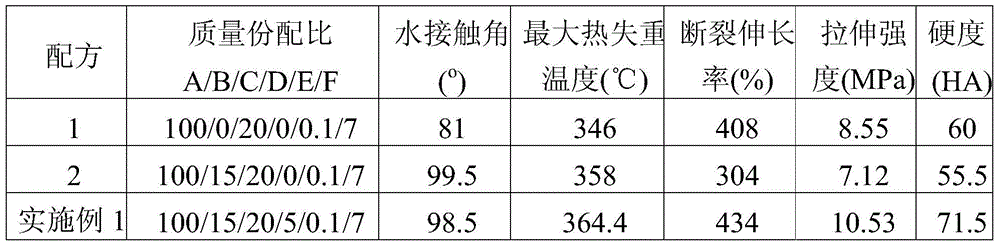

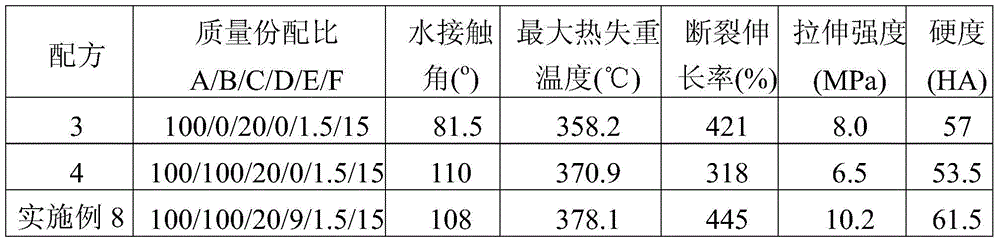

Examples

Embodiment 1

[0063] (1) Preparation of polyether polyurethane prepolymer: In a 500mL three-neck flask equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 17.4g of toluene diisocyanate (TDI) and 100g of polyoxypropylene ether glycol N220 , stirred and reacted at 75°C for 5 hours to obtain a polyether polyurethane prepolymer.

[0064] (2) Preparation of silicone-grafted polyether polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 100g of polyoxypropylene ether triol N330, 17.4g of toluene di Isocyanate (TDI), after stirring and reacting at 80°C for 4 hours, add 6g of single-end hydroxyl polydimethylsiloxane (silanol-terminated, average molecular weight is 15000), 0.1g of organometallic catalyst dibutyltin dilaurate , the temperature was raised to 90° C., and the graft modification reaction was carried out for 4 hours to obtain a silicone-grafted polyether polyureth...

Embodiment 2

[0068] (1) Preparation of polyether polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 17g of hexamethylene diisocyanate (HDI) and 100g of polyoxypropylene ether binary Alcohol N220, stirred and reacted at 85°C for 6 hours to obtain a polyether polyurethane prepolymer.

[0069] (2) Preparation of silicone-grafted polyether type polyurethane prepolymer: In a 500mL three-neck flask equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 100g of polyoxypropylene ether triol N330 and 16.8g of HDI, After stirring and reacting at 85°C for 4 hours, add 30g of single-ended hydroxyl polydimethylsiloxane (silanol-terminated, average molecular weight of 50,000), 0.1g of dibutyltin dilaurate, raise the temperature to 95°C, and carry out connection The branch modification reaction was carried out for 5 hours, and the organosilicon grafted polyether type polyurethane ...

Embodiment 3

[0073] (1) Preparation of polyether polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 150g isophorone diisocyanate (IPDI) and 100g polypropylene glycol PPG300, at 75 Stirring and reacting at ℃ for 10 hours to obtain a polyether type polyurethane prepolymer.

[0074] (2) Preparation of silicone grafted polyether type polyurethane prepolymer: in a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 100g of polyoxypropylene ether tetrahydric alcohol (average molecular weight 5000), 18g IPDI, after stirring and reacting at 75°C for 7 hours, add 15g single-end hydroxyl polydimethylsiloxane (silanol-terminated, average molecular weight is 30000), 0.4g dibutyltin dilaurate, heat up to 95°C , carry out the grafting modification reaction for 4 hours, and obtain the organosilicon grafted polyether type polyurethane prepolymer.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com