Transparent super-hydrophobic nano-coating and spraying and preparation method thereof

A nano-coating, super-hydrophobic technology, applied in coatings, devices for coating liquids on surfaces, pre-treatment of surfaces, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

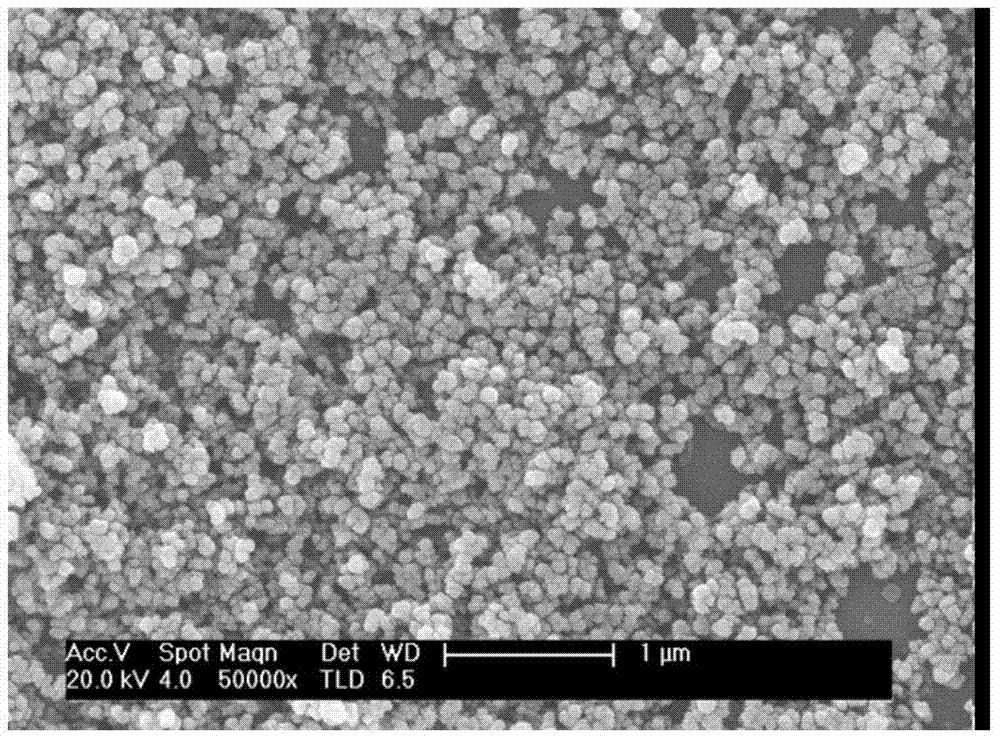

[0023] A preparation and spraying method of a transparent superhydrophobic nano-coating, the steps are:

[0024] (1) Preparation of spray suspension: ultrasonically disperse hydrophobized fumed silica nanoparticles with a diameter of 15-40 nm in acetone solvent at a concentration of 5-20 mg / mL, and sonicate for 10-40 min. Subsequently, the silicone rubber prepolymer is also ultrasonically dissolved in acetone, the concentration is 2-10 mg / mL, and the ultrasonic time is 10-40 min. The equal volumes of the two solutions are fully mixed, and then ultrasonicated for 5-15 minutes to obtain an organic-inorganic hybrid emulsion. After that, add deionized water, the ratio of the added amount to the volume of the emulsion is 1:1-1:9, and then ultrasonically disperse for 10-30 minutes to obtain a spray suspension. The silicone rubber prepolymer is polydimethylsiloxane Alkanes and their derivatives, when preparing polydimethylsiloxane acetone solution, it is necessary to add a curing ag...

Embodiment 1

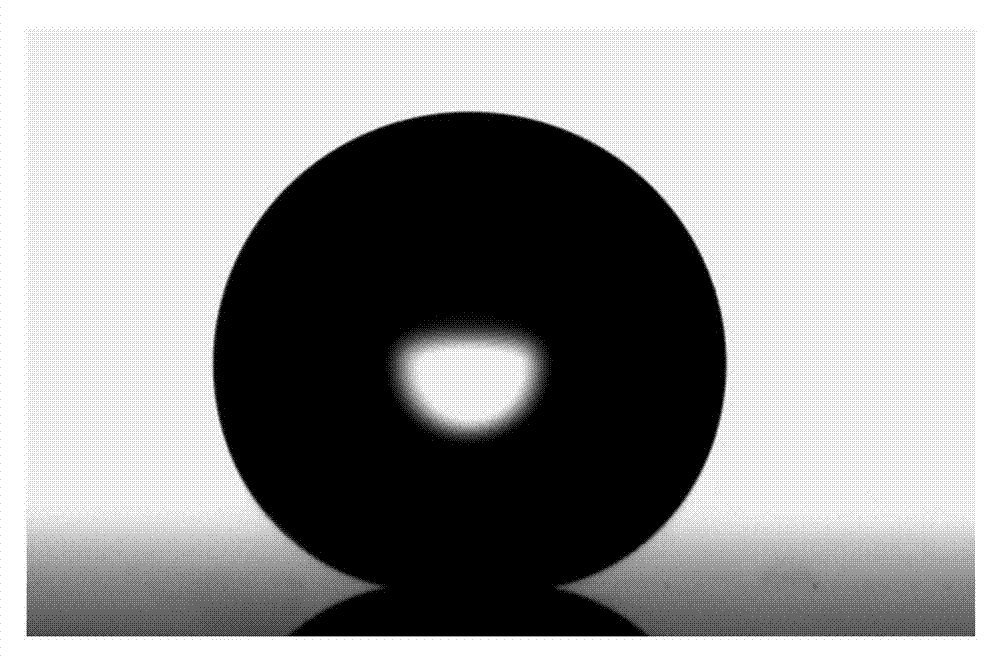

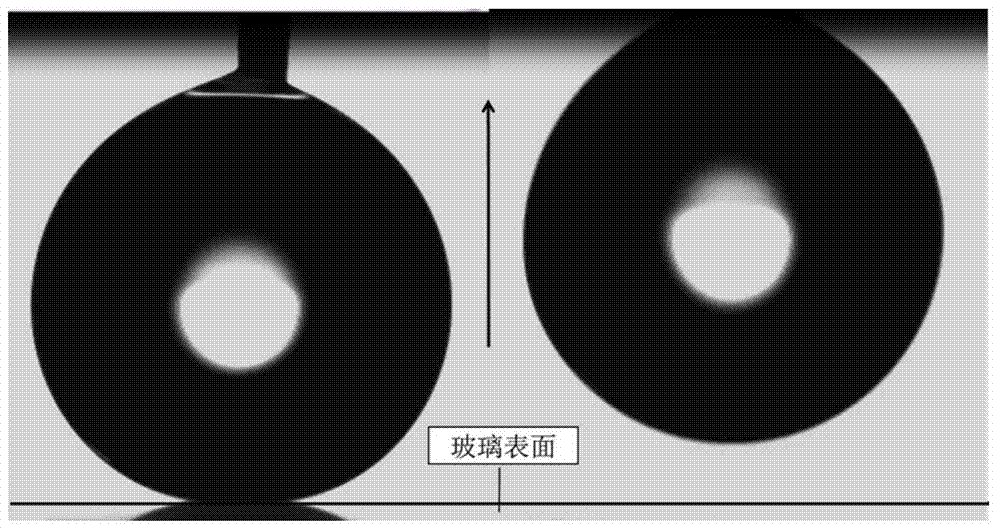

[0028] Hydrophobized fumed silica nanoparticles were ultrasonically dispersed in acetone solvent at a concentration of 5 mg / mL, and ultrasonicated for 10 min. Subsequently, polydimethylsiloxane (Sylgard184) was also dissolved in acetone at a concentration of 3 mg / mL, and a curing agent (Dow Corning, USA) was added at the same time in a weight ratio of 1 to polydimethylsiloxane :10, ultrasonic treatment for 10min on a power 150w ultrasonic dispersing device. The equal volumes of the two solutions were fully mixed, and then ultrasonicated for 5 minutes to obtain an organic-inorganic hybrid emulsion. After that, add deionized water, the ratio of the added amount to the volume of the emulsion is 1:9, and then ultrasonically disperse for 10 minutes to obtain a spray suspension.

[0029] Wipe the square glass with a side length of 50 cm with a cotton cloth. Ultrasonic the spray solution for 5 minutes before spraying, so that the silica nanoparticles and polydimethylsiloxane are unif...

Embodiment 2

[0032] Hydrophilic fumed silica nanoparticles were ultrasonically dispersed in acetone solvent at a concentration of 15 mg / mL, and ultrasonicated for 15 min. Subsequently, polydimethylsiloxane (Sylgard184) was ultrasonically dissolved in acetone at a concentration of 10 mg / mL, and a curing agent (Dow Corning, USA) was added at the same time, and the weight ratio of the added amount to polydimethylsiloxane was 1:10, ultrasonic time 20min. The equal volumes of the two solutions were fully mixed, and then ultrasonicated for 10 minutes to obtain an organic-inorganic hybrid emulsion. After that, add deionized water, the ratio of the added amount to the volume of the emulsion is 1:5, and then ultrasonically disperse for 15 minutes to obtain a spray suspension.

[0033] Clean the slide glass ultrasonically in ethanol for 5 minutes, take it out and dry it, blow it dry or dry it in the air for use. Ultrasonic the spray solution for 5 minutes before spraying, so that the silica nanopa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water droplet contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Water droplet contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com