Method and application of in-situ preparation of heavy metal adsorbent based on high iron and manganese acid mine wastewater

A technology of iron-manganese acidity and in-situ preparation, which is applied in mining wastewater treatment, chemical instruments and methods, water aeration, etc., can solve the problems of increased treatment cost, high cost, large demand for adsorbent use, etc., and achieves improved efficiency. , low cost, to achieve the effect of treatment and comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

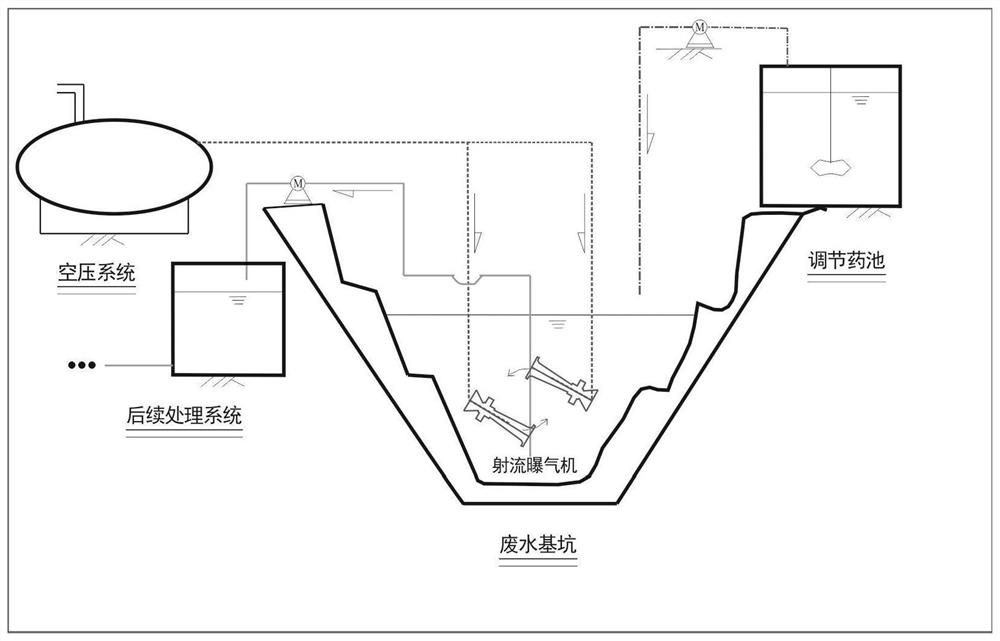

[0032] Such as figure 1 As shown, the method for preparing the heavy metal adsorbent in situ based on ferromanganese acid mine waste water of the present invention, the specific implementation steps include as follows:

[0033] 1. Grind quicklime to 200-mesh powder, and prepare 200-mesh powdered quicklime into a medicament with a concentration of 0.5g / mL. The preparation process of the medicament is completed in the adjustment medicine pool. Keep stirring during the preparation process, and the quicklime is fully dissolved. Form a clear calcium hydroxide solution, so that the calcium hydroxide in the drug will not form a precipitate, and can be fully utilized in the subsequent reaction process;

[0034] 2. Add the medicament prepared in step 1 to the waste water foundation pit of ferric manganese acid mine waste water. For 1 ton of mine water, the dosage rate of the medicament is 0.07L / min, and keep the pH value of the waste water in the waste water foundation pit at 4 left a...

Embodiment 2

[0038]The steps in this embodiment are basically the same as in Example 1, the difference is that in step 1, the quicklime is ground to 150 mesh, and the concentration of the agent configured is 0.6g / mL; in step 2, for 1 ton of mine wastewater, the concentration of the agent is The injection rate is 0.05L / min, the pH value of the wastewater in the wastewater foundation pit is kept at 5, the aeration points are arranged at intervals of 2m, and the aeration treatment time is 3d; in step 3, the standing time is 1.5d.

Embodiment 3

[0040] The steps in this embodiment are basically the same as in Example 1, the difference is that in step 1, the quicklime is ground to 250 mesh, and the concentration of the agent configured is 0.4g / mL; in step 2, for 1 ton of mine waste water, the concentration of the agent is The input rate is 0.1L / min, the pH value of the wastewater in the wastewater foundation pit is kept at 3, the aeration points are arranged at intervals of 1.8m, the aeration treatment time is 2d, and in step 3, the standing time is 2.0d.

[0041] The heavy metal adsorbent obtained in the embodiment of the present invention can be used for arsenic-containing wastewater treatment after simple drying, and the heavy metal adsorbent is added to the arsenic-containing wastewater, and the arsenic adsorption treatment rate can reach more than 60%.

[0042] The preparation principle of the present invention is as follows: ferrous ions are oxidized to ferric ions under aeration treatment, and some suspended matt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com