Preparation method and application of zirconium dioxide/porous polyaniline modified electrode

A technology of zirconium dioxide and modified electrodes, which is applied in the direction of material electrochemical variables, can solve the problems of poor chemical/physical stability of enzymes or antibodies, and achieve good catalytic performance, wide linear range, and low detection line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation method of zirconium dioxide / porous polyaniline modified electrode

[0032] Instruments and reagents used in this embodiment:

[0033] CHI832 electrochemical analyzer (Shanghai Chenhua Instrument Co., Ltd.) was used for square wave voltammetry experiment; Ag / AgCl reference electrode (Shanghai Ridao Scientific Instrument Co., Ltd.); electronic balance (Beijing Sartorius Instrument Co., Ltd.) was used for weighing Quantitative drugs; JSM-6701F cold field emission scanning electron microscope (Japan Electronics Co., Ltd.) was used for morphology characterization; aluminum oxide grinding powder (0.30 μm, 0.05 μm, Shanghai Chenhua Instrument Reagent Co., Ltd.) was used to process glassy carbon electrodes; Aniline (purity 99.78%), zirconium oxychloride, sulfuric acid, potassium perchlorate (Tianjin Kaixin Chemical Industry Co., Ltd.), high-purity nitrogen (purity 99.999%, O 2 ≤0.001%).

[0034] The specific operation steps are as follows:

[0035] a) Befor...

Embodiment 2

[0040] Zirconium dioxide / porous polyaniline modified electrodes (ZrO 2 -3D PANI / GCE) on the electrochemical performance of methyl parathion

[0041] Zirconium dioxide / porous polyaniline modified electrode in KClO dissolved with methyl parathion 4 The solution was plotted by square wave voltammetry.

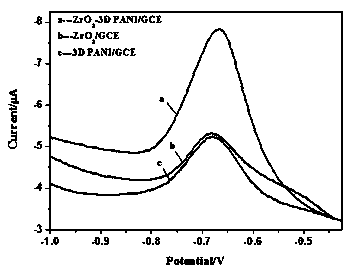

[0042] From figure 2It can be seen that compared with zirconium dioxide and porous polyaniline modified electrode, zirconium dioxide / porous polyaniline modified electrode has a good catalytic effect on the detection of methyl parathion, and in the process of reducing methyl parathion ZrO2 / Porous Polyaniline Synergy for Electrocatalysis of Methylparathion.

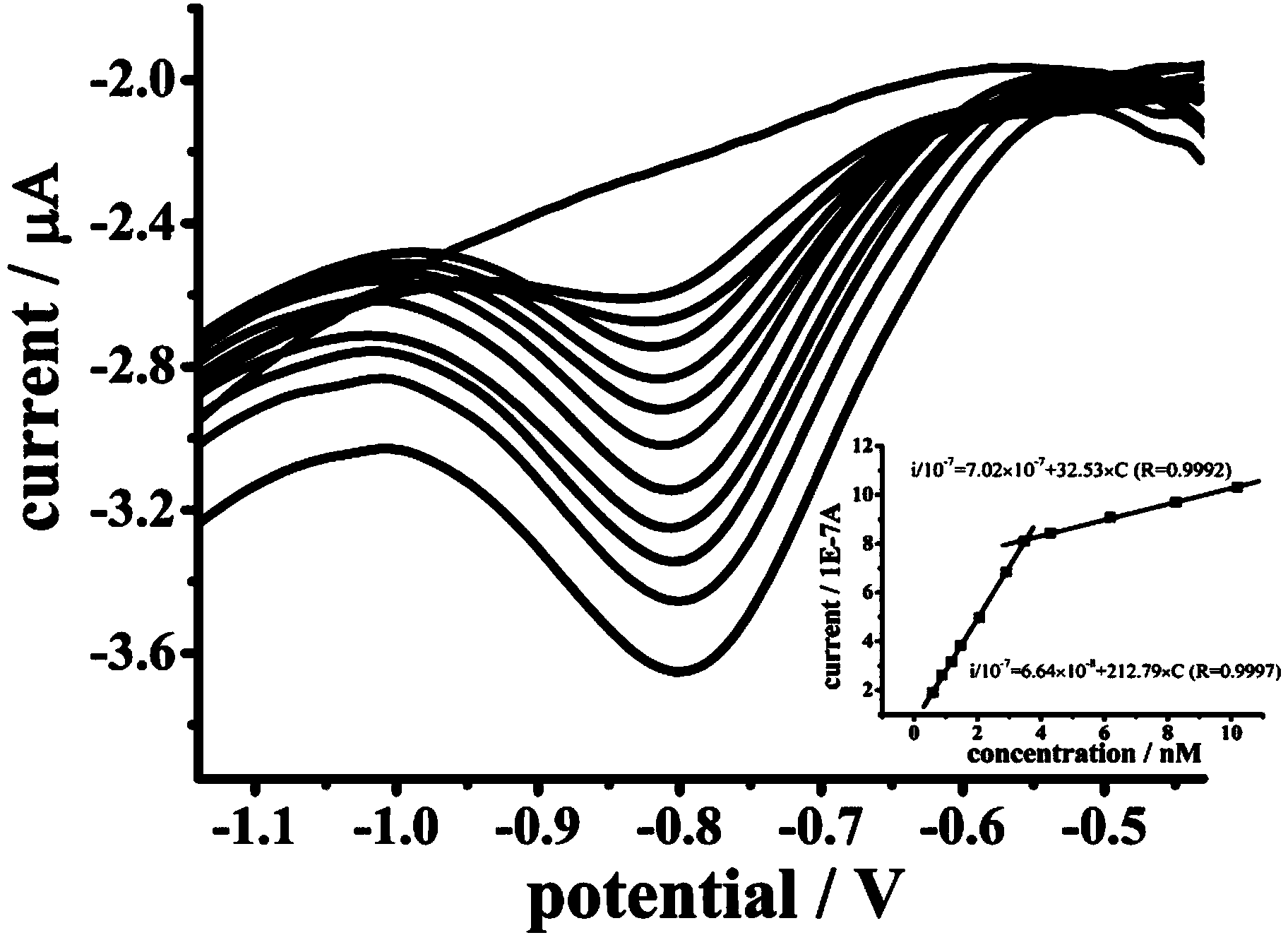

[0043] From image 3 It can be seen that the zirconia / porous polyaniline modified electrode has high sensitivity to the electrochemical reduction of methyl parathion, and the detection linear range is 5.964×10 -10 nM to 1.020×10 -8 nM, the detection limit is 2.991×10 -10 nM.

[0044] From Figure 4 It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com