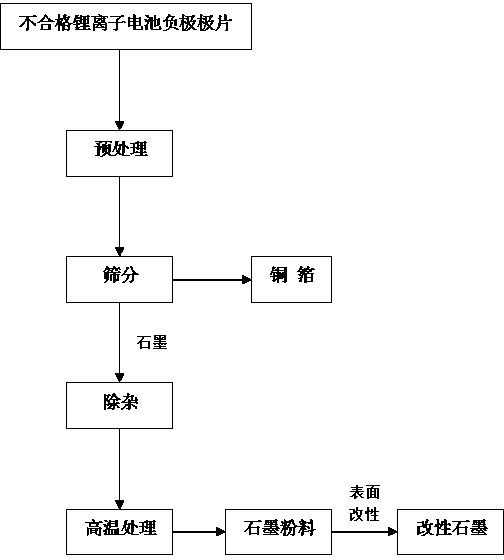

Recycling method for disqualified lithium ion battery negative electrode materials in graphite system

A lithium-ion battery and anode material technology, applied in the field of anode material recycling, can solve problems such as ignoring the importance of efficient recycling of graphite raw materials, achieve high added value of products, simple process flow, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Negative pole pieces refer to unqualified lithium ion negative pole pieces using graphite system.

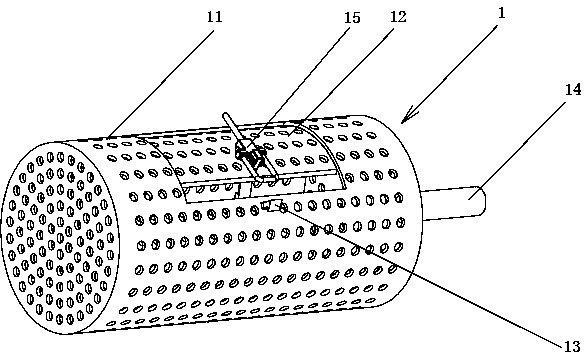

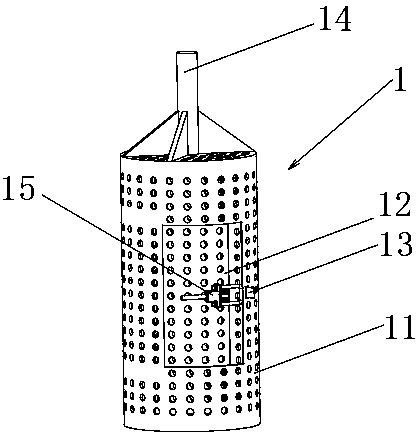

[0045] Put 3kg of unqualified lithium-ion battery negative electrodes into a sieve drum with a length of 70cm and a diameter of 30cm, and then soak it into a 100L drum container filled with 0.1mol / L sodium pyrophosphate solvent for 20 minutes. Take out the sieve cylinder and connect it to the output shaft of the motor on the operating table of the small hoist, then drive the lifting device to lower the sieve cylinder into the 100L container containing the aqueous solution, the motor drives the sieve cylinder to rotate, and the lifting device drives the sieve cylinder to operate Reciprocating motion in the vertical direction, the working time is 20 minutes, under the synergistic effect of mechanical motion and water flow shearing and scouring, the graphite is completely separated from the copper foil, flows out and settles to the bottom of the container through the sieve ho...

Embodiment 2

[0050] Put 3.5kg of unqualified negative pole pieces of lithium-ion batteries into a sieve cylinder with a length of 80cm and a diameter of 40cm, and then soak them in a 100L drum container filled with 0.15mol / L sodium pyrophosphate solvent for 15min . Take out the sieve cylinder and connect it to the output shaft of the motor on the operating table of the small hoist, then drive the lifting device to lower the sieve cylinder into the 100L container containing the aqueous solution, the motor drives the sieve cylinder to rotate, and the lifting device drives the sieve cylinder to operate Reciprocating motion in the vertical direction, the working time is 20 minutes, under the synergistic effect of mechanical motion and water flow shearing, the graphite flakes are completely separated from the copper foil, and settle down to the container through the sieve holes with a diameter of 2 cm on the surface of the sieve cylinder At the bottom, it is pumped to the centrifuge by the slur...

Embodiment 3

[0055]Put 4kg of unqualified lithium-ion battery negative electrodes into a sieve cylinder with a length of 90cm and a diameter of 50cm, and then soak it into a 100L drum container filled with 0.25mol / L sodium pyrophosphate solvent for 10 minutes. Take out the screen cylinder and connect it to the operating table of the small elevator machine, then lower the screen cylinder into the 100L container containing the aqueous solution for vertical reciprocating motion, the working time is 20min, under the synergistic effect of mechanical movement and water scouring Next, the graphite flakes are completely separated from the copper foil, settle down to the bottom of the container through the sieve holes with a diameter of Φ2cm on the surface of the sieve cylinder, and then are pumped by the slurry pump to the centrifuge for washing, filtering and drying, and finally get a water content of 20 -30% graphite slag; the current collector in the pole piece still remains in the sieve drum, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com