Hydrophilization modification method of polyolefin hollow fiber ultrafiltration membrane

A polyolefin and ultrafiltration membrane technology, which is applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problem of loss of hydrophilic modified coating or modified adsorbent, and difficulty in obtaining permanent hydrophilic modification. problems such as non-resistance, impossibility of hydrophilic modification of ultrafiltration membrane pores, etc., to achieve excellent chemical resistance, low cost of modification, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A polyolefin hollow fiber ultrafiltration membrane with a pore size of 30 to 50 nanometers prepared by polyvinyl chloride using a melt-spinning-stretching (MSCS) method is made into a standard external pressure hollow fiber membrane module with a diameter of 4 inches.

[0083] Add dopamine hydrochloride as a solute to a tris buffer solution (with water as a solvent), adjust its pH by adding hydrochloric acid dropwise, and prepare dopamine hydrochloride-tris modified with a concentration of 2g / L and a pH value of 8.5 solution.

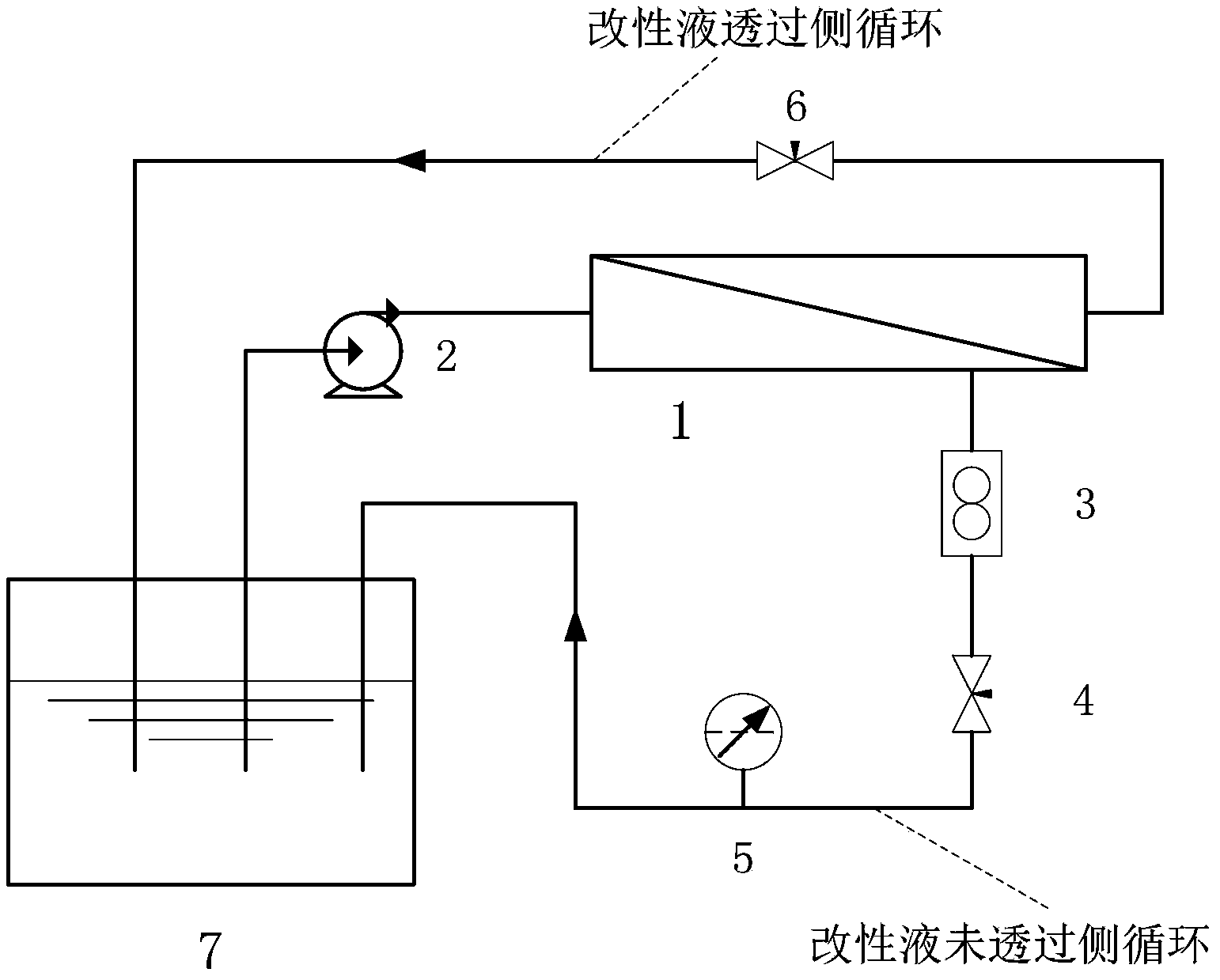

[0084] Such as figure 1 As shown, the prepared dopamine hydrochloride-tris modified solution stored in the raw material tank 7 is passed through the pump 2 into the external pressure hollow fiber membrane module, and the external pressure operation is adopted. By adjusting the speed of the pump 2 and the first pressure regulating valve 4, the transmembrane pressure is adjusted so that the dopamine hydrochloride-tris modified solution is infiltra...

Embodiment 2

[0089] Polyvinylidene fluoride (PVDF) polyolefin hollow fiber ultrafiltration membrane with a pore size of 30 to 50 nanometers prepared by thermally induced phase separation (TIPS) method is made into a standard external pressure hollow fiber membrane module with a diameter of 9 inches.

[0090] Add dopamine hydrochloride as a solute to a tris buffer solution (with water as a solvent), adjust its pH by adding hydrochloric acid dropwise, and prepare dopamine hydrochloride-tris modified with a concentration of 0.1g / L and a pH value of 8.5. neutral solution.

[0091] Such as figure 1 As shown, the prepared dopamine hydrochloride-tris modified solution stored in the raw material tank 7 is passed through the pump 2 into the external pressure hollow fiber membrane module, and the external pressure operation is adopted. By adjusting the rotational speed of the pump 2 and the first pressure regulating valve 4, the transmembrane pressure is adjusted, so that the dopamine hydrochloride...

Embodiment 3

[0096] The polyolefin hollow fiber ultrafiltration membrane with an average pore size of 150-200 nanometers prepared from polyethylene (PE) by the thermally induced phase separation (TIPS) method is made into a standard external pressure hollow fiber membrane module with a diameter of 9 inches.

[0097] Add dopamine hydrochloride as a solute to tris buffer solution (water and methanol as solvent, mass ratio is 1:1), adjust its pH by adding hydrochloric acid dropwise, and prepare the concentration to be 10g / L, the pH value 10 dopamine hydrochloride-tris modified solution.

[0098] Such as figure 1 As shown, the prepared dopamine hydrochloride-tris modified solution stored in the raw material tank 7 is passed through the pump 2 into the external pressure hollow fiber membrane module, and the external pressure operation is adopted. By adjusting the rotating speed of the pump 2 and the first pressure regulating valve 4, the transmembrane pressure is adjusted, so that the dopamine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com