Sulfur-tolerant shift catalyst and preparation method thereof

A sulfur-resistant conversion and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of increasing the preparation process and affecting the active components cobalt and molybdenum Uniform dispersion, unfavorable synergism and other problems, to achieve the effect of simplifying the operation steps, increasing the stability of the activity, and improving the distribution mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

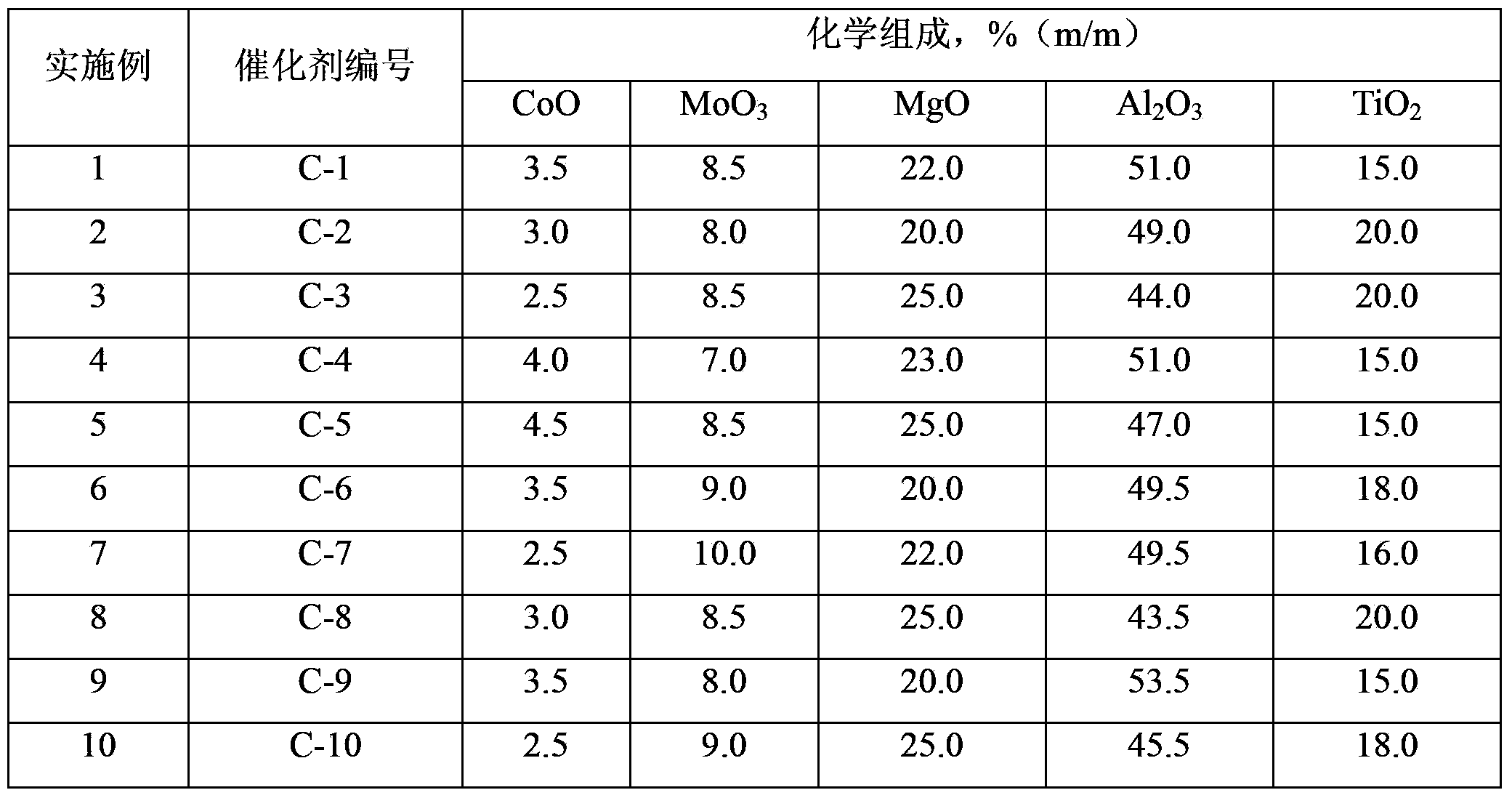

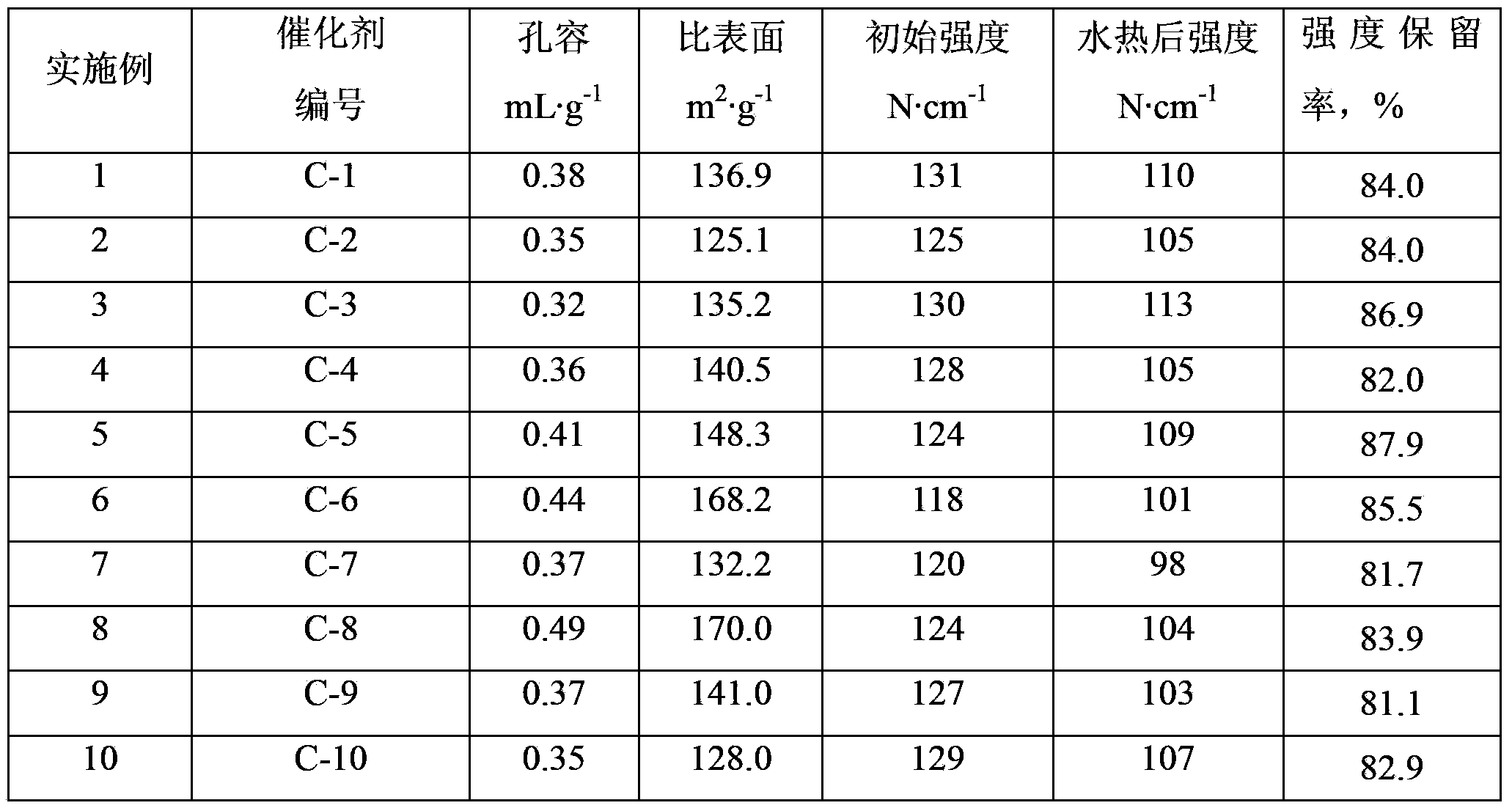

[0044] The chemical composition of the prepared catalyst of embodiment 1~10 is listed in table 1:

[0045] Table 1 Catalyst Composition

[0046]

[0047] The preparation method of each catalyst of the present invention is as follows:

[0048] Catalyst C-1:

[0049] Weigh 11.31g of cobalt oxalate, 10.46g of ammonium molybdate, and 22.50g of ammonium oxalate, add 40ml of deionized water, stir mechanically and heat to 70°C to prepare solution A containing both cobalt and molybdenum active components in one step.

[0050] Mix 22.10g of light magnesia, 57.14g of pseudoboehmite, 18.75g of metatitanic acid and 22.56g of aluminum glue as a powdery solid compound, add solution A, knead evenly; extrude into strips.

[0051] Leave at room temperature to dry naturally. By means of gradient heating, the temperature was raised from 20°C to 120°C over 1 hour, kept at 120°C for 2 hours, then raised to 550°C over 1 hour, and the catalyst was calcined at 550°C for 5 hours to obtain catalyst...

Embodiment 11

[0089] Catalyst Performance Evaluation:

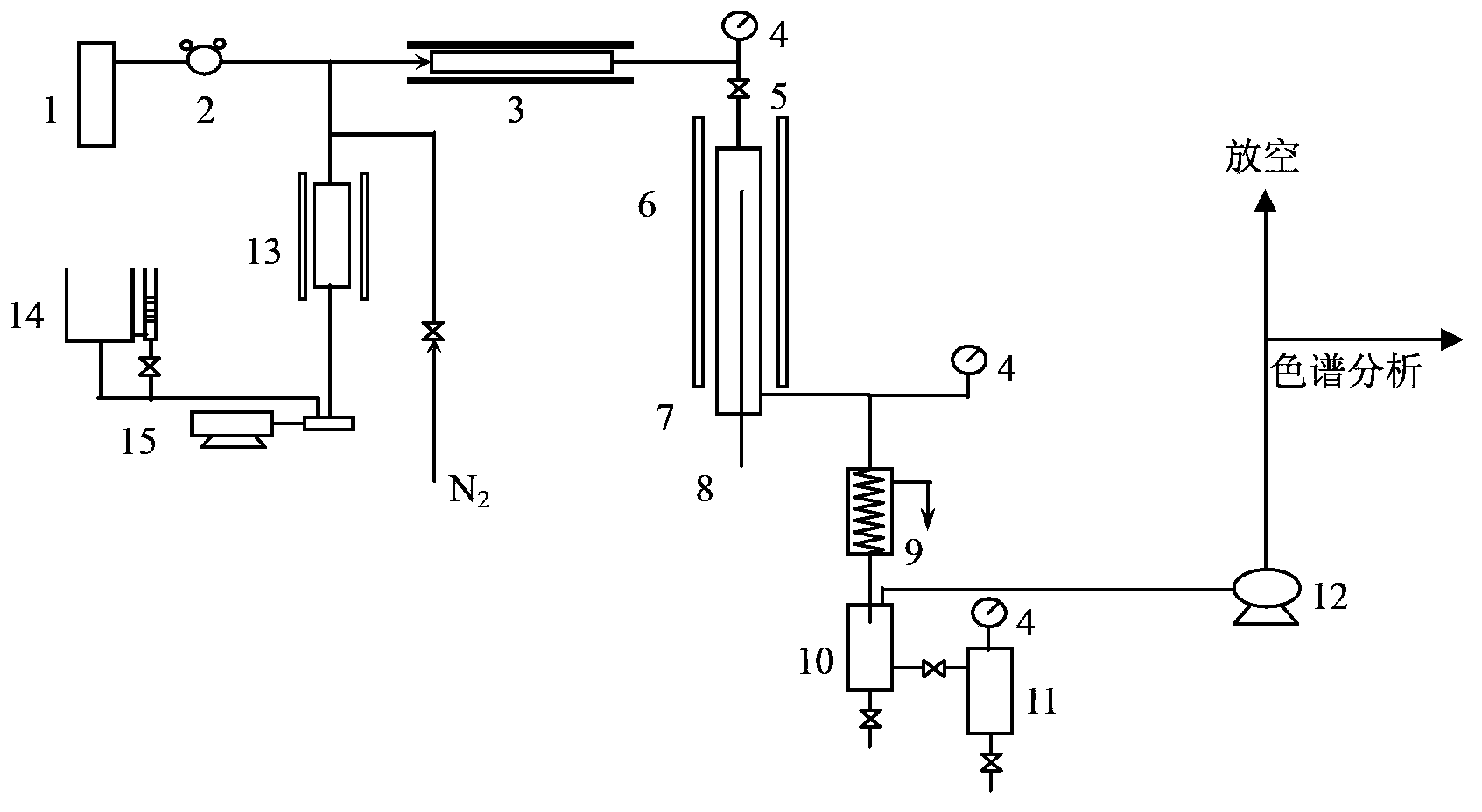

[0090] Catalyst activity evaluation is carried out on a pressurized original particle size evaluation device, such as figure 1 Shown is a conventional device. It is used to simulate industrial conditions, measure the CO concentration and its change of the original particle size catalyst under different conditions, and evaluate various performances such as catalyst activity and stability. A synthetic ammonia workshop is used to convert the previous process gas into the raw material gas, and add an appropriate amount of H 2 S gas, according to the requirements of different water-gas ratios, makes the high-temperature vaporized water vapor react with the raw material gas in the reaction tube, and the tail gas after the reaction is analyzed by chromatography.

[0091] The pressure evaluation conditions are:

[0092] Catalyst loading: 100mL (Φ4mmα-Al 2 o 3 Balls 1:1 diluted filling)

[0093] Catalyst particle size: Φ4mm×4mm

[0094] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com