Method and application of a photosensitizer for preparing a composite photocatalyst

A technology of compounding light and photosensitizer, applied in the field of material science, can solve the problems of limited application, low separation and transfer efficiency, etc., to achieve the effect of promoting coating and bonding, easy availability of raw materials, and reducing the probability of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

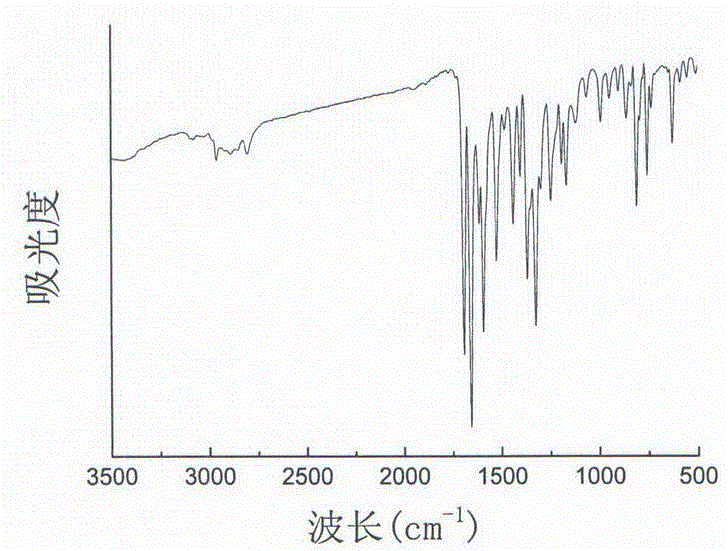

[0032] Photosensitizer N, the synthesis of N'-dimethylamino-p-benzyl-perylene diimide:

[0033] Weigh 784.6mg of 3,4,9,10-perylenetetracarboxylic anhydride, 901.4mg of N,N'-dimethylamino-p-benzylamine, 20g of imidazole and 18mg of zinc acetate into a 100mL three-neck round bottom flask , oil bath at 120°C, magnetically stirred for 5 hours, then cooled and poured into a 500mL single-necked round-bottomed flask containing 100mL of absolute ethanol. After magnetically stirred for half an hour, 300mL of 2M hydrochloric acid aqueous solution was added, magnetically stirred for 12 hours, and then pumped Filter, wash with water, wash with methanol, and finally dry at 80°C for 12 hours to obtain N,N'-dimethylamino-p-benzyl-perylenediimide powder;

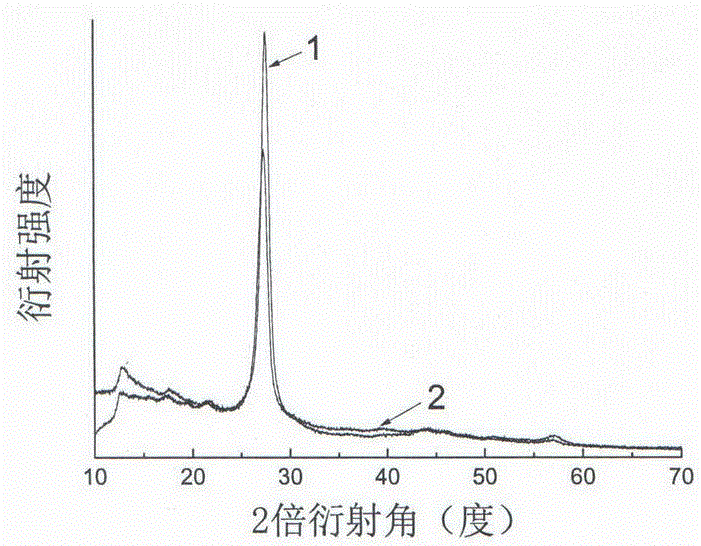

[0034] Preparation of composite photocatalyst substrate platinum / graphite-like carbon nitride:

[0035] Weigh 5 g of melamine, put it into a porcelain crucible after grinding, spread it evenly, put it into a muffle furnace for calcination ...

Embodiment 2

[0041] Photosensitizer N, the synthesis of N'-dimethylamino-p-benzyl-perylene diimide:

[0042] Weigh 784.6mg of 3,4,9,10-perylenetetracarboxylic anhydride, 901.4mg of N,N'-dimethylamino-p-benzylamine, 20g of imidazole and 18mg of zinc acetate into a 100mL three-neck round bottom flask , oil bath temperature 120 ℃, magnetic stirring reaction for 5 hours, after cooling and pouring into a 500mL single-necked round bottom flask containing 100mL absolute ethanol, after magnetic stirring for half an hour, add 300mL 2M hydrochloric acid aqueous solution, magnetic stirring for 12 hours, then Suction filtration, washing with water, washing with methanol, and finally drying at 80°C for 12 hours to obtain N,N'-dimethylamino-p-benzyl-perylenediimide powder;

[0043] Preparation of composite photocatalyst substrate platinum / graphite-like carbon nitride:

[0044] Weigh 5 g of melamine, put it into a porcelain crucible after grinding, spread it evenly, put it into a muffle furnace for calc...

Embodiment 3

[0050] Photosensitizer N, the synthesis of N'-dimethylamino-p-benzyl-perylene diimide:

[0051] Weigh 784.6mg of 3,4,9,10-perylenetetracarboxylic anhydride, 901.4mg of N,N'-dimethylamino-p-benzylamine, 20g of imidazole and 18mg of zinc acetate into a 100mL three-neck round bottom flask , oil bath temperature 120 ℃, magnetic stirring reaction for 5 hours, after cooling and pouring into a 500mL single-necked round bottom flask containing 100mL absolute ethanol, after magnetic stirring for half an hour, add 300mL 2M hydrochloric acid aqueous solution, magnetic stirring for 12 hours, then Suction filtration, washing with water, washing with methanol, and finally drying at 80°C for 12 hours to obtain N,N'-dimethylamino-p-benzyl-perylenediimide powder;

[0052] Preparation of composite photocatalyst substrate platinum / graphite-like carbon nitride:

[0053] Weigh 5 g of melamine, put it into a porcelain crucible after grinding, spread it evenly, put it into a muffle furnace for calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com