A resistance brazing method and device using graphite electrodes

A technology of resistance brazing and graphite electrodes, which is applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problem of the decline in the quality of hard alloy products, the decline in the yield and service life of hard alloy brazing workpieces, etc. problems, to achieve the effect of strong combination reliability, low brazing cost, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

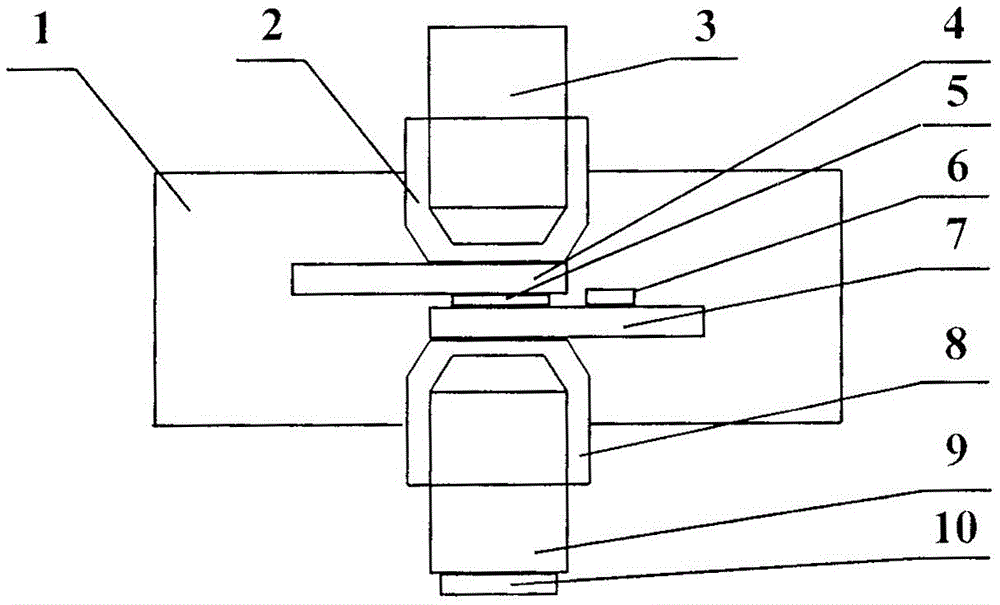

[0029] In the first step, the YG15 hard alloy brazing parts 4, 45 to be brazed # The surface of the carbon steel brazing part 7 is cleaned with dilute hydrochloric acid or sodium hydroxide aqueous solution, the surface oxide film is removed, and cleaned by wiping with acetone;

[0030] In the second step, the B-Mn50NiCuCrCo solder 5 used for brazing with a thickness of 0.3mm is first polished with sandpaper to remove the surface oxide film, and then wiped clean with acetone;

[0031] The third step is to first place the 45 that needs to be brazed # Put the carbon steel brazing piece 7 into the brazing chamber 1, then place the manganese-based B-Mn50NiCuCrCo brazing material 5 on the corresponding position of the carbon steel brazing connection, and spread a small amount of 102 flux on the brazing material, and then put the YG15 Carbide brazing parts 4 are placed on the solder;

[0032] The fourth step is to operate the resistance brazing device, set the welding current to 12...

Embodiment 2

[0035] In the first step, the surfaces of the YG3 hard alloy brazing parts 4 and 40Cr alloy steel brazing parts 7 to be brazed are cleaned with dilute hydrochloric acid or sodium hydroxide aqueous solution, the surface oxide film is removed, and cleaned by wiping with acetone;

[0036] In the second step, the B-Mn65NiCoFeB solder 5 used for brazing with a thickness of 0.1mm is first polished with sandpaper to remove the surface oxide film, and then wiped clean with acetone;

[0037]In the third step, the 40Cr alloy steel brazing piece 7 that needs to be brazed is put into the brazing chamber 1, then the manganese-based B-Mn65NiCoFeB brazing filler metal 5 is placed on the corresponding position of the carbon steel brazing connection, and the brazing Sprinkle a small amount of 102 flux on the material, and then put the YG3 cemented carbide brazing piece 4 on the solder;

[0038] The fourth step is to operate the resistance brazing device, set the welding current to 10000A, set ...

Embodiment 3

[0041] The first step, the YT5 cemented carbide brazing parts 4, 40 to be brazed # The surface of the carbon steel brazing part 7 is cleaned with dilute hydrochloric acid or sodium hydroxide aqueous solution, the surface oxide film is removed, and cleaned by wiping with acetone;

[0042] In the second step, the B-Mn50NiCuCrCo solder 5 used for brazing with a thickness of 0.05mm is first polished with sandpaper to remove the surface oxide film, and then wiped clean with acetone;

[0043] The third step is to first place the 40 that needs to be brazed # Put the carbon steel brazing piece 7 into the brazing chamber 1, then place the nickel-based B-Ni75CrSiB solder 5 on the corresponding position of the carbon steel brazing connection, and spread a small amount of 102 flux on the solder, and then put the YT5 Carbide brazing parts 4 are placed on the solder;

[0044] The fourth step is to operate the resistance brazing device, set the welding current to 7000A, set the welding tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com