Egg white-based wood adhesive

A wood adhesive, egg white-based technology, applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of lack of glue, insufficient viscosity and high fluidity on the surface of the wood board, and improve the bonding strength, The effect of low cost and low liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

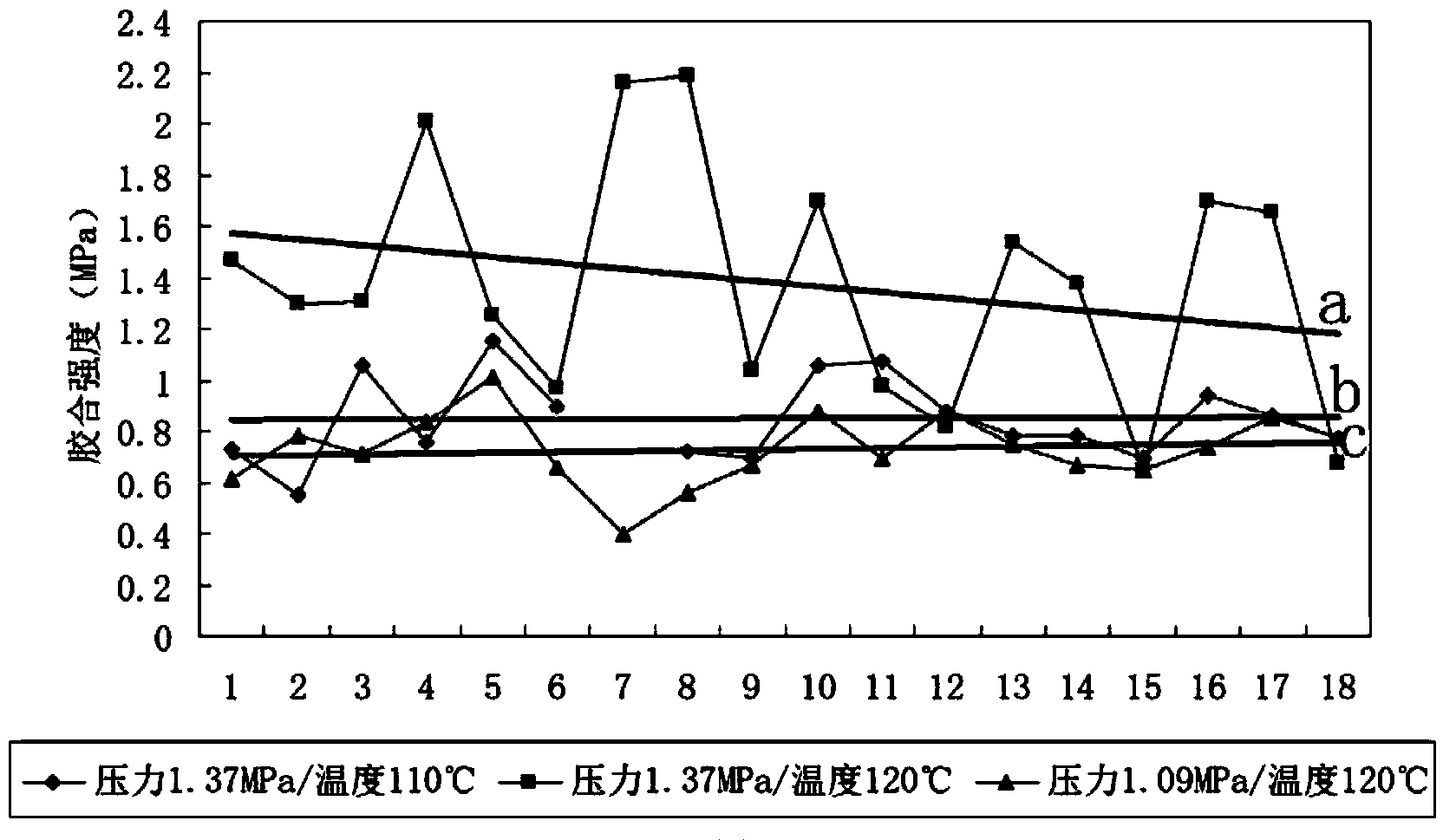

Image

Examples

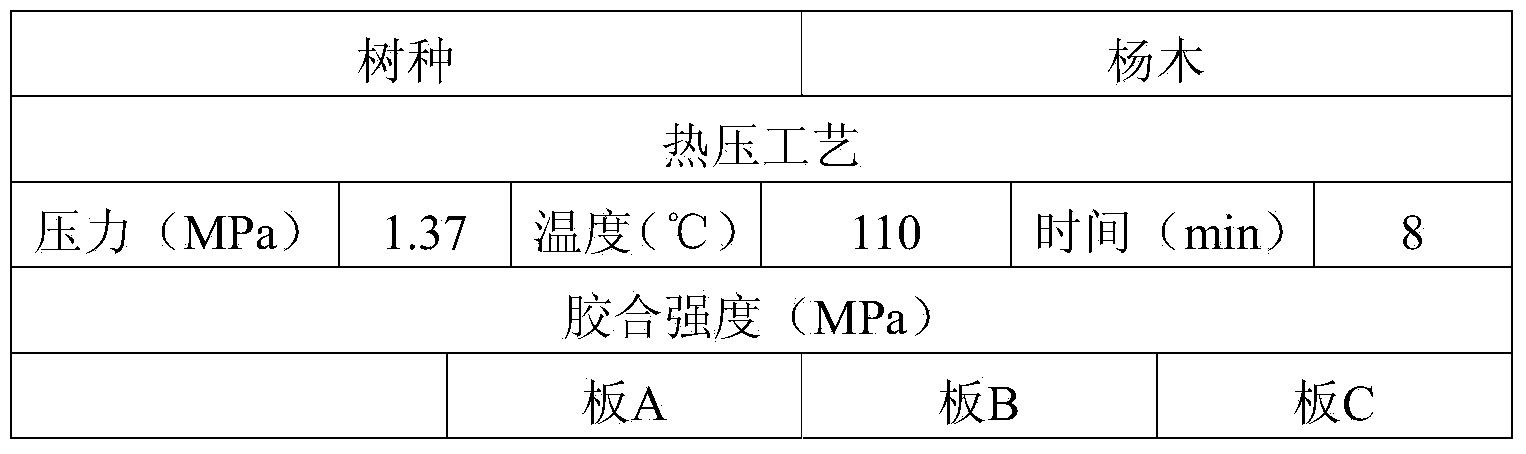

Embodiment 1

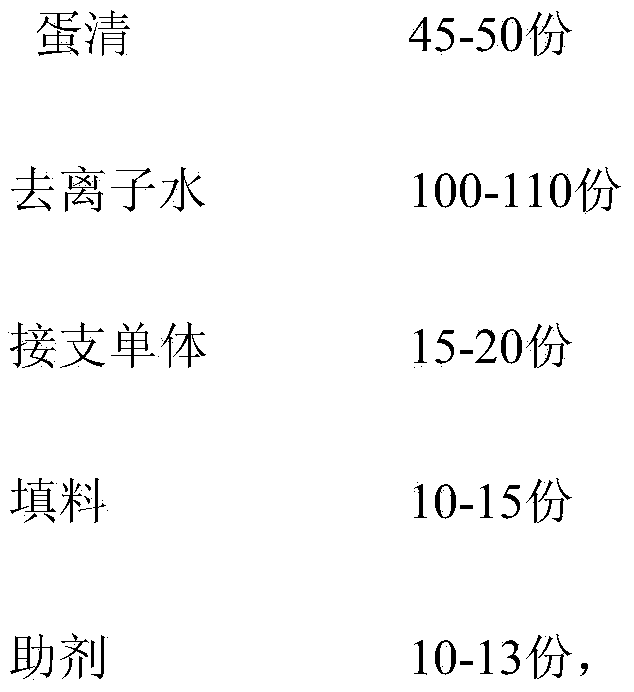

[0034] This embodiment provides an egg white-based wood adhesive, which comprises the following components in parts by mass: egg white: 45 parts, deionized water: 110 parts, glycidyl methacrylate: 4 parts, aqueous Epoxy resin emulsion: 12 parts, kaolin: 10 parts, additives: 13 parts,

[0035] Among them, the auxiliary agent is composed of the following components in terms of mass percentage, urea: 36%, sodium bisulfite: 9%, ammonium persulfate: 6%, formic acid: 3%, octanol: 6%, dodecylsulfonate Sodium phosphate: 8%, polyvinyl alcohol: 20%, diethylenetriamine: 13%.

[0036] In this embodiment, the water-based epoxy resin emulsion is composed of the following components by mass percentage: E-44 epoxy resin: 16%, polyethylene glycol PEG-4000: 62%, potassium persulfate: 8%, deionized Water: 14%;

[0037] The preparation method of aqueous epoxy resin emulsion is specifically carried out in the following steps:

[0038] (1) First put E-44 epoxy resin into an oven and preheat at 4...

Embodiment 2

[0043]This embodiment provides an egg white-based wood adhesive, which comprises the following components in parts by mass: egg white: 50 parts, deionized water: 105 parts, glycidyl methacrylate: 5 parts, aqueous Epoxy resin emulsion: 15 parts, kaolin clay: 15 parts, additives: 10 parts,

[0044] Among them, the auxiliary agent is composed of the following components in terms of mass percentage, hexamethylenetetramine: 40%, sodium bisulfite: 7%, ammonium persulfate: 7%, formic acid: 2%, tributyl phosphate: 7%, Sodium Lauryl Sulfonate: 5%, Phthalates: 22%, Diaminodiphenylmethylsulfone DDS: 10%.

[0045] In this embodiment, the water-based epoxy resin emulsion is composed of the following components by mass percentage: E-44 epoxy resin: 15%, polyethylene glycol PEG-4000: 65%, potassium persulfate: 7%, deionized Water: 13%;

[0046] The preparation method of aqueous epoxy resin emulsion is specifically carried out in the following steps:

[0047] (1) First put the E-44 epoxy r...

Embodiment 3

[0052] This embodiment provides an egg white-based wood adhesive, which comprises the following components in parts by mass: egg white: 48 parts, deionized water: 100 parts, glycidyl methacrylate: 4 parts, aqueous Epoxy resin emulsion: 12 parts, kaolin: 12 parts, additives: 11 parts,

[0053] Wherein, the auxiliary agent is composed of the following components by mass percentage, sodium hydroxide: 27%, sodium bisulfite: 6%, ammonium persulfate: 5%, sodium benzoate: 4%, octanol: 8%, dodecyl alcohol: Sodium alkylbenzene sulfonate: 10%, styrene-butadiene latex: 25%, m-phenylenediamine: 15%.

[0054] In this embodiment, the water-based epoxy resin emulsion is composed of the following components by mass percentage: E-44 epoxy resin: 14%, polyethylene glycol PEG-4000: 64%, potassium persulfate: 8%, deionized Water: 14%;

[0055] The preparation method of aqueous epoxy resin emulsion is specifically carried out in the following steps:

[0056] (1) First put E-44 epoxy resin into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com