High heat-resistant low-fluidity adhesive for rigid-flexible printed circuit board, adhesive film and preparation method of high heat-resistant low-fluidity adhesive

A printed circuit board, rigid-flex combination technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of high fluidity of the adhesive film, thick adhesive film, unfavorable environmental protection, etc., and achieve good flexibility , Improve cross-linking density, high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

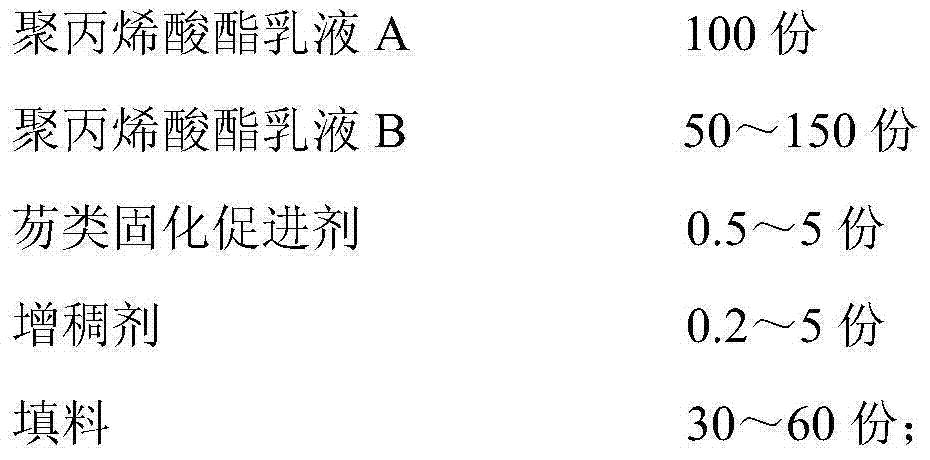

Method used

Image

Examples

Synthetic example A1

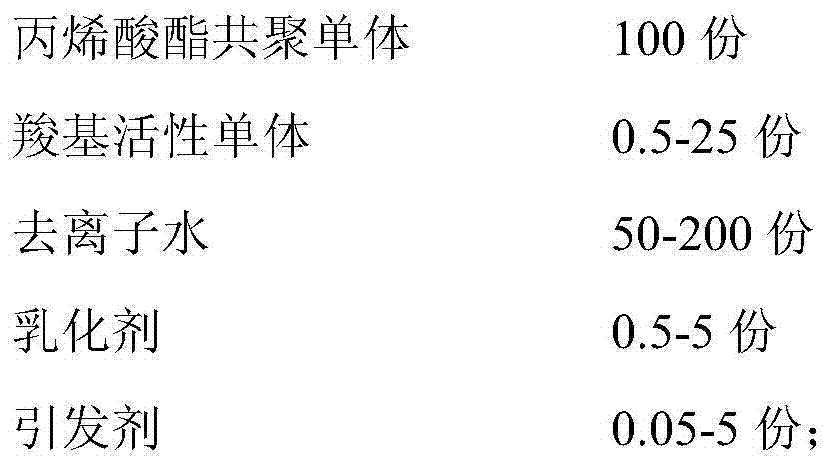

[0039]In the reactor, add emulsifying agent 2kg sodium lauryl sulfate, 1kg op-10, deionized water 150kg, initiator potassium persulfate 0.25kg, acrylate comonomer methyl methacrylate 10kg, styrene 15kg, 10kg of butyl acrylate, 15kg of isooctyl acrylate, and 2.5kg of carboxyl monomer acrylic acid, under the protection of nitrogen, slowly stir and raise the temperature to initiate the reaction. Seed emulsion; then at 75°C to 80°C, slowly drop the remaining acrylate comonomer methyl methacrylate 10kg, styrene 15kg, butyl acrylate 10kg, acrylate isooctyl 15kg, carboxyl monomer acrylic acid 2.5 kg of the mixture was dripped in about 2-4 hours, and then 0.25 kg of the remaining initiator potassium persulfate was added, kept at 80°C for 1-3 hours, cooled and discharged to obtain the polyacrylate emulsion A1.

Synthetic example A2~A5

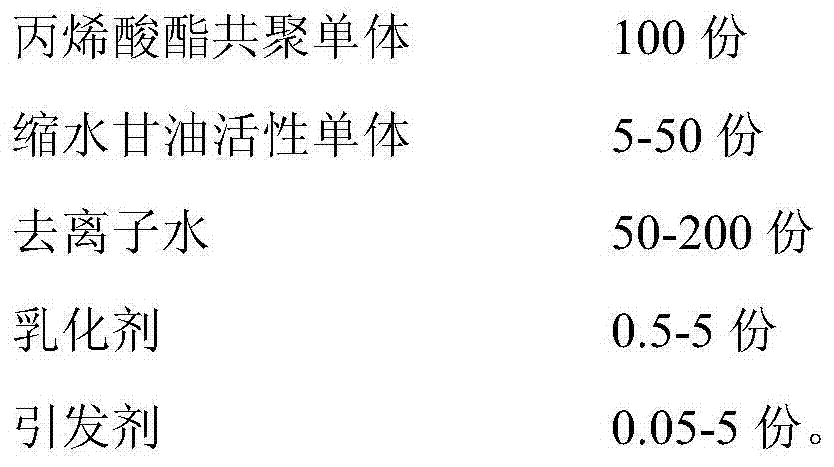

[0040] Synthesis example A2~A5, B1~B5

[0041] The synthesis methods and conditions of Synthesis Examples A2~A5, B1~B5 are the same as those of Synthesis Example A1, except that the type and quality of each raw material are different. In the synthesis of B1~B5, the carboxyl-active monomers are replaced with corresponding shrinkage resins in the following table. Glycerin active monomer.

[0042] Table 1 shows the raw materials of Synthesis Examples A2 to B5.

[0043] The raw material list of table 1 synthesis example A1~B5

[0044]

[0045]

[0046] Preparation of adhesive and preparation of high heat-resistant low-fluidity adhesive film for rigid-flexible printed circuit boards:

Embodiment 1

[0049] Add 100kg of polyacrylate emulsion A1, 60kg of polyacrylate emulsion B1, and 35kg of ultrafine aluminum silicate in the ball mill barrel, and grind and disperse in the ball mill for 12 to 72 hours; dissolve 0.5kg of BPEF in 50kg of absolute ethanol, and add to Stir evenly into the above latex solution; finally add 0.6kg HEC to adjust the viscosity to 1500-2000cps, filter through a 300-mesh filter and set aside for use.

[0050] Coat the above prepared glue solution on the polyester release film through a coating machine, control the thickness of the dry glue after drying to 10-25 μm, and then compound the polyester release film to prepare rigid-flexible printing High heat resistance and low fluidity adhesive film for circuit boards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com