Tobacco pyrolysis combustion reactor, analysis system and method

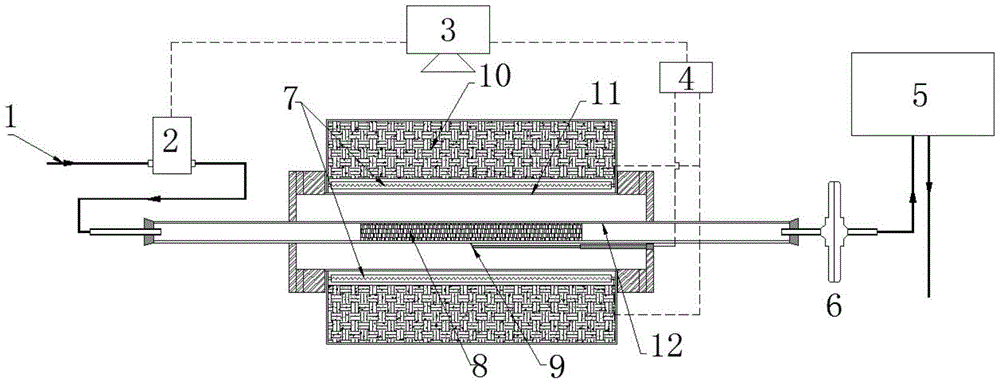

A combustion analysis and reactor technology, which is applied in the tobacco industry, can solve the problems of low cut tobacco volume and poor repeatability of experimental data, and achieve the effects of high heating rate, controllable reaction atmosphere, and controllable flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

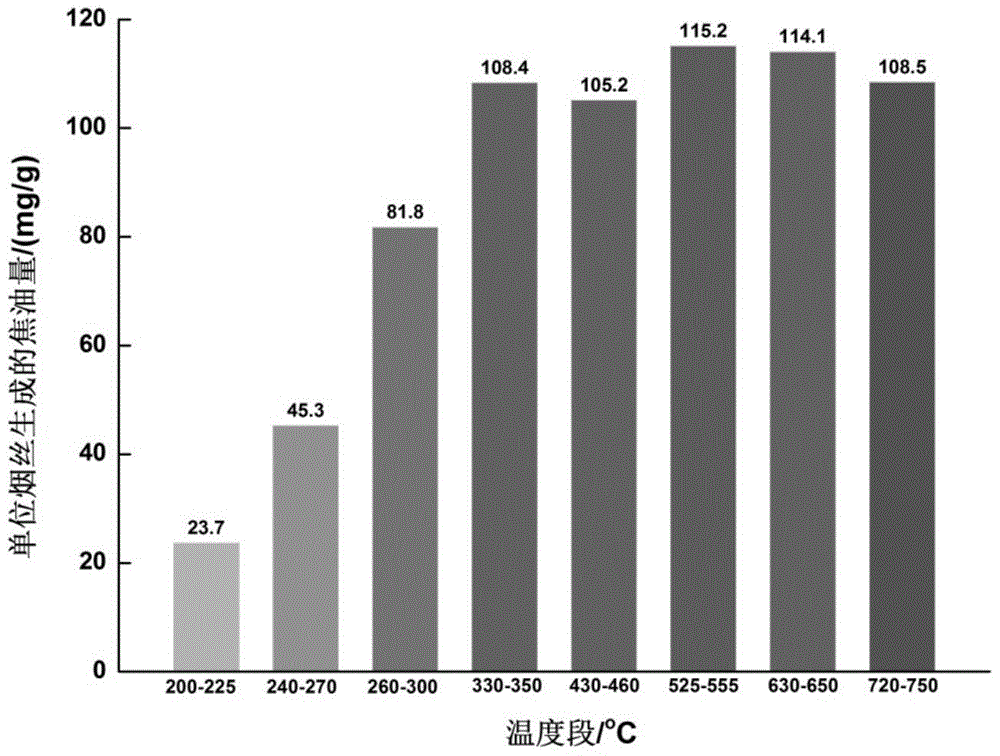

[0079] Embodiment 1: Tar release experiment

[0080] Put 4 pieces of flue-cured tobacco shreds with a weight of 1g into the quartz glass tube of the tobacco pyrolysis combustion reactor respectively, pass air in, the flow rate is 2000mL / min, and the temperature is raised to 330°C-350°C at a rate of 20°C / s , 430°C-460°C, 525°C-555°C and 630°C-650°C, all burned for 10 minutes, and measured according to the national standard GB / T 19609-2004 "Determination of total particulate matter and tar by smoking machine for routine analysis of cigarettes" Obtain the tar release amount of flue-cured tobacco shredded tobacco burned at the above-mentioned temperature in the air.

Embodiment 2

[0085] Embodiment 2: fragrance component release experiment

[0086] Put 2 parts of flue-cured tobacco shreds with a weight of 1g into the quartz glass tube of the tobacco pyrolysis combustion reactor respectively, pass air in, the flow rate is 2000mL / min, and the temperature is raised from room temperature to 430°C at a rate of 20°C / s. -460°C and 525°C-555°C, burn for 10 minutes to end the reaction. Fold the Cambridge filter and put it into a flat-bottomed flask, then add 50mL of dichloromethane and 100μL of 50mg / mL internal standard solution of phenylethyl acetate to soak for 15min, seal it and ultrasonicate for 30min at room temperature, let it stand for 5min, and filter through a micropore After membrane filtration, it was concentrated to 1 mL, analyzed by gas chromatography-mass spectrometry, and calculated by internal standard method to obtain the aroma components of flue-cured tobacco shredded tobacco burning in air: acetic acid, oleic acid, linoleic acid, palmitic ac...

Embodiment 3

[0090] Embodiment 3: CO release experiment

[0091] Put 1g of flue-cured tobacco shreds, expanded shredded tobacco, shredded stems and thin slices into the quartz glass tube of the tobacco pyrolysis combustion reactor respectively, and feed 2% (volume percentage) O 2 -98% (volume percent) of N 2 , the flow rate is 2000mL / min, and the temperature is raised to 250°C at a rate of 20°C / s for combustion. After burning for 10 minutes, the IR infrared sensor (detection range 0-20000ppm) of the flue gas analysis device is used to detect flue-cured tobacco shreds, expanded shredded tobacco, and shredded stems. and flakes at 2% (volume percent) O 2 -98% (volume percent) of N 2 The amount of CO released by combustion at 250°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com