Resin composition, prepreg, resin sheet, and metal foil-clad laminate

A resin composition and compound technology, applied in the fields of resin sheets, metal foil-clad laminates, prepregs, and resin compositions, can solve the problem of lowering the glass transition temperature of resin compositions, harmful nitrogen oxides, and deteriorating heat resistance. and other problems, to achieve the effects of excellent electrical properties, high industrial practicability, and excellent moisture absorption and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

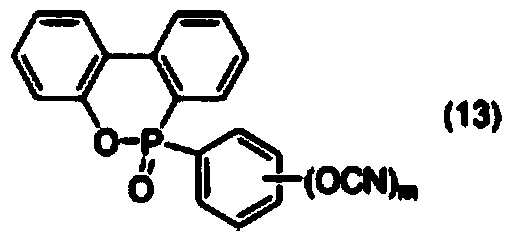

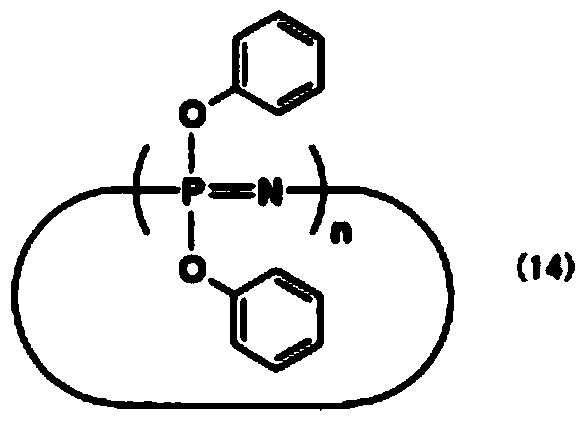

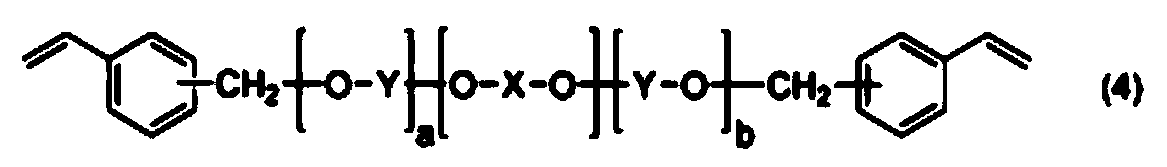

[0146] Vinylbenzyl-modified polyphenylene ether (OPE-2St1200, polyphenylene oligomers with vinyl groups at both ends (2,2',3,3',5,5'-hexamethylbiphenyl- Reaction product of 4,4'-diol-2,6-dimethylphenol polycondensate and chloromethylstyrene), manufactured by Mitsubishi Gas Chemical Co., Ltd., number average molecular weight: 1187, vinyl equivalent: 590g / eq.) 55 parts by mass, 2.0 parts by mass of a phosphorous cyanate compound (FR-300, produced by Ronza Japan Co., Ltd., cyanate equivalent: 187g / eq.) in which m is 2 in the above formula (13), the above formula (14 ) in which n is a mixture of 3 to 6, 18.8 parts by mass of a cyclic phosphazene compound (FP-100, manufactured by Fushimi Pharmaceutical Co., Ltd.), cresol novolak type epoxy resin (N680, manufactured by DIC CORPORATION, epoxy equivalent: 215g / eq.) 8.9 parts by mass, bisphenol A type cyanate compound (CA210, manufactured by Mitsubishi Gas Chemical Co., Ltd., cyanate equivalent: 139g / eq.) 12.8 parts by mass, styrene ol...

Embodiment 2

[0155] The compounding quantity of the phosphorus cyanate compound (FR-300) was changed to 5.0 mass parts, the compounding quantity of the cyclic phosphazene compound (FP-100) was changed to 17.0 mass parts, and the cresol novolak type epoxy The compounding quantity of the resin (N680) was changed to 9.3 parts by mass, the compounding quantity of the cyanate compound (CA210) was changed to 11.2 parts by mass, and the compounding quantity of manganese octoate was changed to 0.043 parts by mass. Example 1 was carried out in the same manner. Table 1 shows various physical property values of the obtained double-sided copper-clad laminate.

Embodiment 3

[0157] The compounding quantity of vinylbenzyl-modified polyphenylene ether (OPE-2St1200) was changed to 53 mass parts, the compounding quantity of phosphorus cyanate compound (FR-300) was changed to 3.0 mass parts, and the cyclic phosphine The compounding quantity of the nitrile compound (FP-100) was changed to 18.0 mass parts, the compounding quantity of the cresol novolak type epoxy resin (N680) was changed to 7.0 mass parts, and the compounding quantity of the cyanate compound (CA210) was changed to The amount was changed to 12.4 parts by mass, and 4.6 parts by mass of bisphenol A epoxy resin (E-1051, manufactured by DIC CORPORATION, epoxy equivalent: 475g / eq.) was blended, and an imidazole compound (2P4MZ, Shikoku Chemicals Co., Ltd. system) 0.10 parts by mass instead of manganese octoate, and carried out in the same manner as in Example 1 except that. Table 1 shows various physical property values of the obtained double-sided copper-clad laminate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com