Nemadectin purification method

A technology of nimoctin and purification method, applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., can solve the problems of difficulty in using nimoctin, low purity of nimoctin, high energy consumption, etc. , to achieve the effect of simple and easy method, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

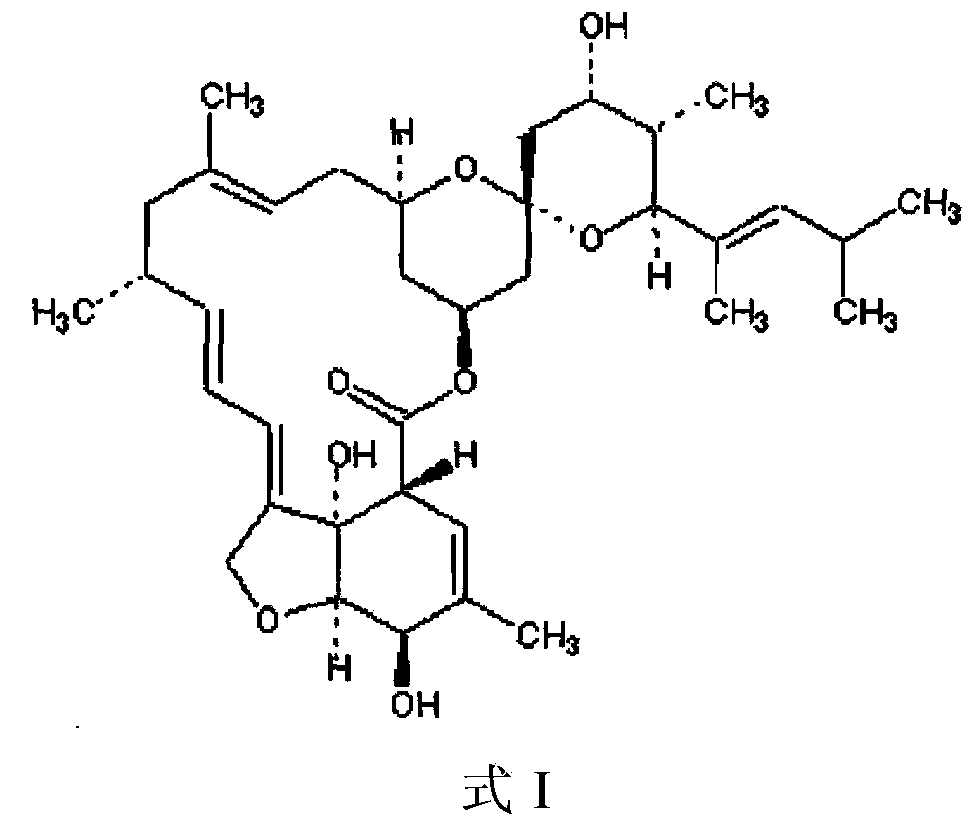

Image

Examples

Embodiment 1

[0077] Preparation of diethylamine acetate: add 100ml of acetic acid into 180ml of diethylamine under stirring, set aside.

[0078] Adjust the pH of 10 L of nimoctine fermentation broth to 3.1 with dilute sulfuric acid, and filter to obtain 451.2 g of filter cake; add 1.5 L of isopropanol for extraction, filter to obtain a filtrate; concentrate and recover isopropanol. Add 0.6L of dichloromethane to the solid mixture, add 0.4L of 5% sodium bicarbonate solution, stir and wash for 1h, let stand to separate layers; take the upper layer, concentrate and recover the solvent to obtain 50.2g of crude product of nimoctine, the HPLC purity is 35.67% .

[0079] Add 200ml of diethylamine acetate to the obtained crude nemoctin, stir to dissolve, and filter; add 60ml of heptane to the filtrate for extraction, remove the lower layer, cool to -2~0°C, add 250ml of water dropwise under stirring, crystallize, filter, and use 15 % (v / v) isopropanol aqueous solution, and dried under reduced pres...

Embodiment 2

[0081] Preparation of triethylamine acetate: add 100ml of acetic acid into 243ml of triethylamine under stirring, set aside.

[0082] Adjust the pH of 10 L of nimoctine fermentation broth to 3.2 with dilute hydrochloric acid, and filter to obtain 463.5 g of filter cake; add 1.2 L of isopropanol for extraction, and filter to obtain a filtrate; concentrate to recover isopropanol. Add 0.5 L of dichloromethane to the solid mixture, add 0.35 L of 5% sodium bicarbonate solution, stir and wash for 1 h, let stand to separate layers; take the upper layer, concentrate and recover the solvent to obtain 52.4 g of crude product of nimoctine, the HPLC purity is 33.59% .

[0083]Add 220 ml of triethylamine acetate to the obtained crude nemoctin, stir to dissolve, and filter; add 70 ml of hexane to the filtrate for extraction, remove the lower layer, cool to -5-4°C, add 250 ml of water dropwise under stirring, crystallize, filter, and use 15 % (v / v) isopropanol aqueous solution, dried under ...

Embodiment 3

[0085] Preparation of diethylamine acetate: add 100ml of acetic acid into 180ml of diethylamine under stirring, set aside.

[0086] Adjust the pH of 10 L of nimoctine fermentation broth to 5.0 with phosphoric acid, and filter to obtain 475.6 g of filter cake; add 1.5 L of ethanol to extract, filter to obtain a filtrate; concentrate to recover ethanol. Add 0.6L of dichloromethane to the solid mixture, add 0.4L of 5% sodium bicarbonate solution, stir and wash for 1h, let it stand for stratification; take the upper layer, concentrate and recover the solvent to obtain 55.4g of crude product of nimoctine, the HPLC purity is 30.71% .

[0087] Add 200ml of diethylamine acetate to the obtained crude nemoctin, stir to dissolve, and filter; add 60ml of methylcyclohexane to the filtrate for extraction, remove the lower layer, cool to -1~0°C, add 250ml of water dropwise under stirring, crystallize, and filter , washed with 20% (v / v) aqueous ethanol, and dried under reduced pressure to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com