Modified graphene for efficiently adsorbing methyl orange dye and preparation method of modified graphene

A technology of graphene and methyl orange, which is applied in the field of modified graphene and its preparation, can solve the problems that chitosan quaternary ammonium salt and graphene composite materials have not yet appeared, hinder the application of graphene, and poor dispersion, and achieve good Water solubility and biological activity, easy handling, effect of reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

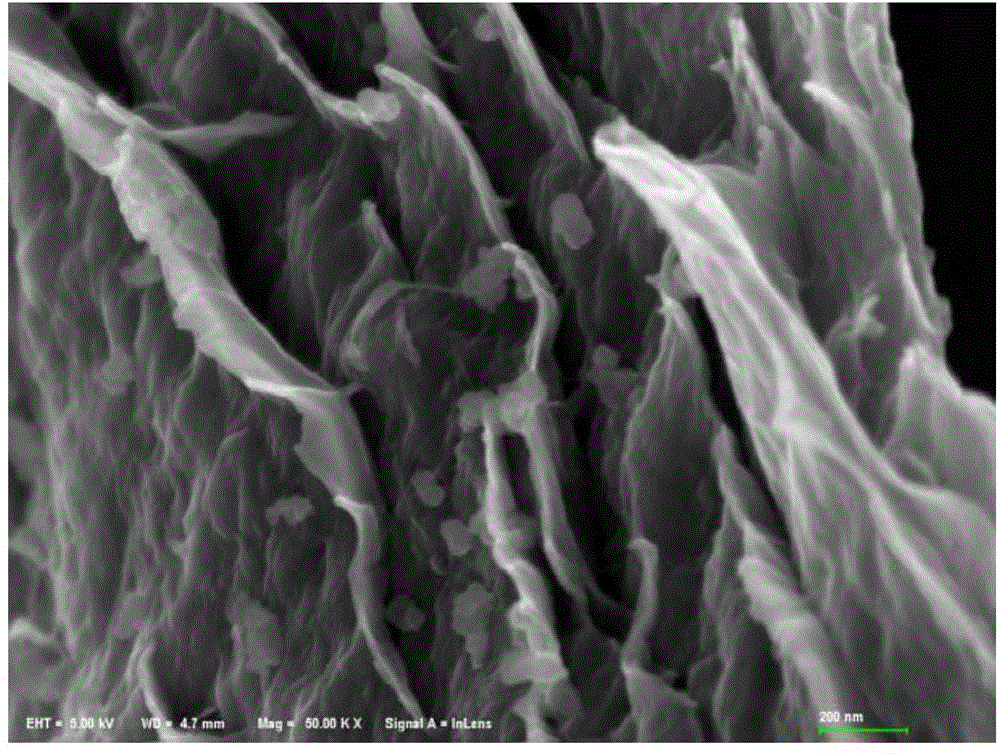

Image

Examples

Embodiment 1

[0026] (1) Adopt modified Hummers method to synthesize graphite oxide, concrete steps are as follows:

[0027] Place the flask filled with 46ml of concentrated sulfuric acid (98%) in an ice-water bath and cool it to 0°C, take 2.0g of natural flake graphite and slowly add it to the concentrated H 2 S0 4 and stir rapidly until uniformly dispersed. 6.0gKMnO 4 and 1.0g NaNO 3 Slowly add it into the above flask, try to control the temperature at 10°C to 15°C, and continue stirring for 2h. Then the resulting mixture was transferred to a constant temperature (35° C.) water bath and stirred for 2 h. Add 130ml of distilled water in batches, keep the temperature under 90°C and continue the reaction for 30min, then add 150ml of distilled water to dilute. Finally, add a certain amount of hydrogen peroxide with a volume fraction of 30% until the mixture turns bright yellow, filter, and fully wash the filter product with 5% HCl solution until the sulfate ion SO in the filter cake produ...

Embodiment 2

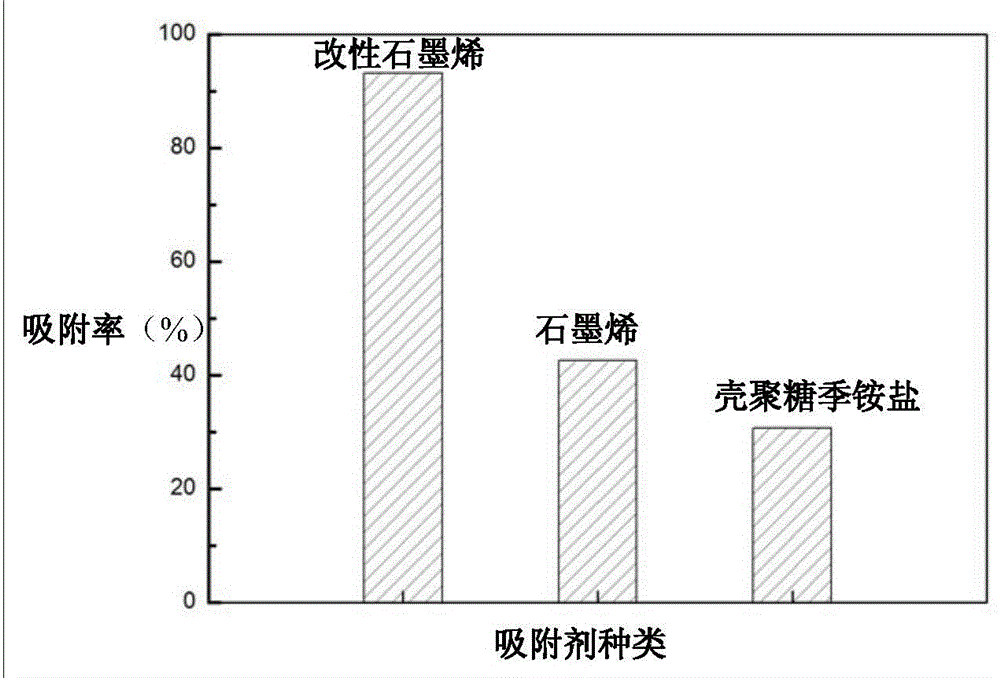

[0031] The amount of graphite oxide was changed to 0.06g and 0.15g, the high temperature reaction temperature was 60°C, and other conditions remained unchanged, and two kinds of modified graphenes implemented in this case were prepared according to step (2) of Example 1. Add the prepared modified graphene to the methyl orange solution with an initial concentration of 34mg / L, the amount of adsorbent is 0.2g / L, the pH value of the solution is 7, the rotational speed of the oscillation reaction is 100rpm, and the time of the oscillation reaction 8h, the adsorption temperature is 30 ℃, when the amount of graphite oxide is 0.06g and 0.15g, the adsorption rate of methyl orange is 81.13% and 85.67%, respectively.

Embodiment 3

[0033]Change the concentration of 2-hydroxypropyltrimethylammonium chloride chitosan aqueous solution to 7mg / mL and 3mg / mL, the normal temperature reaction time is 2h, and other conditions remain unchanged, prepare this case according to the step (2) of Example 1 Implemented two modified graphene. Add the prepared modified graphene to the methyl orange solution with an initial concentration of 34mg / L, the amount of adsorbent is 0.2g / L, the pH value of the solution is 7, the rotational speed of the oscillation reaction is 100rpm, and the time of the oscillation reaction 8h, the adsorption temperature is 30 ℃, when the concentration of chitosan quaternary ammonium salt solution is 7mg / mL and 3mg / mL, the adsorption rate of methyl orange is 96.10% and 81.93%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com