Catalyst for producing caprolactam as well as preparation method and application thereof

A technology of caprolactam and catalyst, which is applied to the catalyst for producing caprolactam and the field of preparation and application thereof, can solve the problems of low catalyst activity, poor stability, and excessive ammonium sulfate, and achieves improved reaction activity, improved stability, and increased hydrophobicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

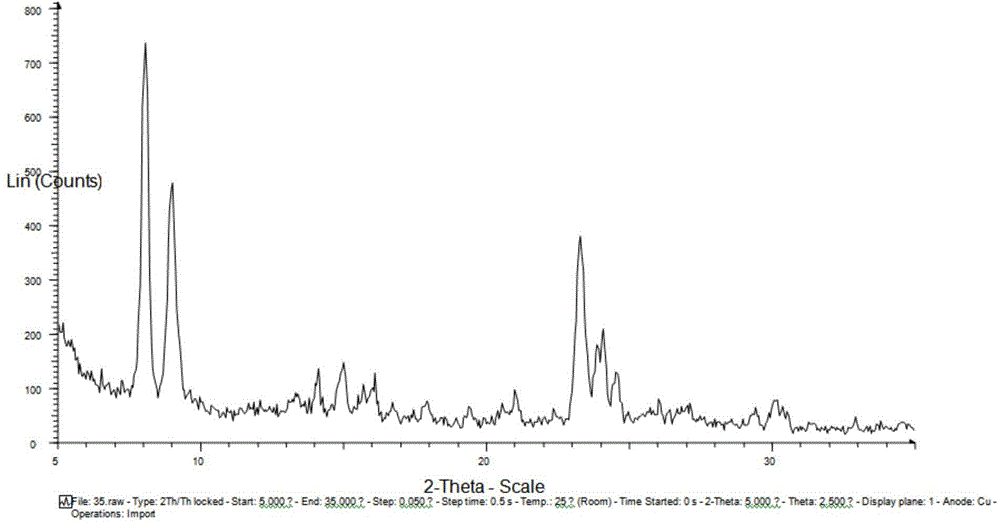

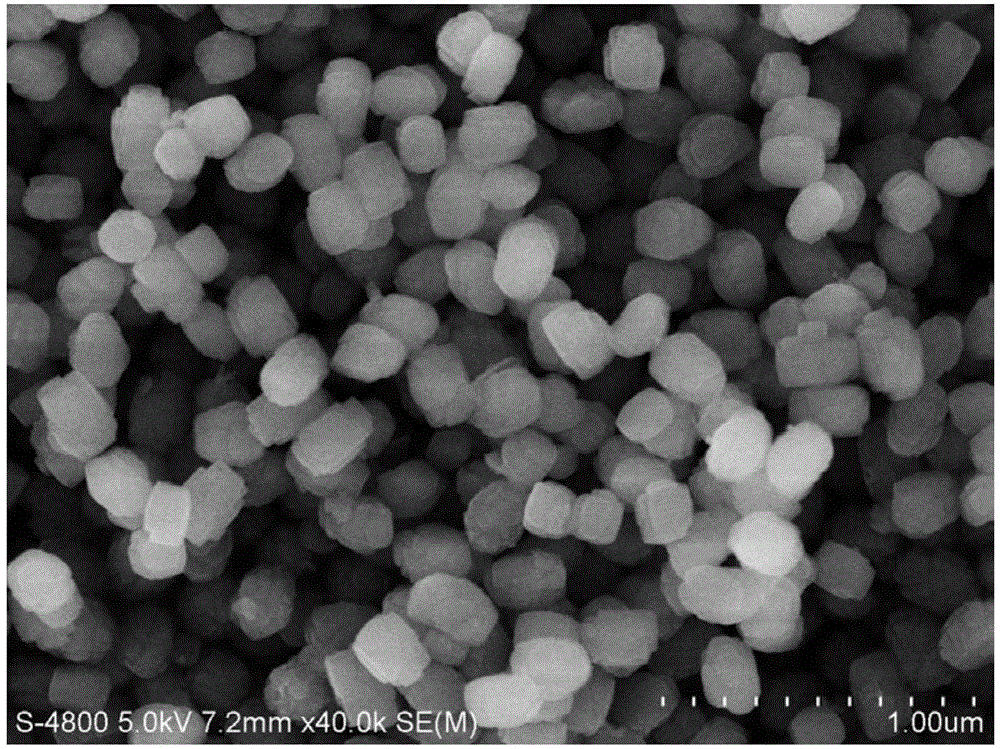

[0038] Take 650 grams of ethyl orthosilicate, hydrolyze it with 530 grams of water and 700 grams of 25% tetrapropylammonium hydroxide aqueous solution for one hour, then heat it up to 70°C and remove the alcohol for 2 hours, then transfer the colloid to the autoclave Raise the temperature to 170°C to crystallize for 60 hours, filter, wash and dry, and calcinate at 550°C for 5 hours to obtain the all-silica ZSM-5 zeolite molecular sieve. The XRD spectrum and the scanning electron microscope SEM image are as follows: figure 1 , 2 , It is proved that it is a typical MFI zeolite molecular sieve with a crystal grain size of about 300nm. 50 grams of 25% tetrapropylammonium hydroxide aqueous solution, 30 grams of diethylamine and 30 grams of dimethyldiethoxysilane are dissolved in 500 grams of water to obtain a mixed aqueous solution. Take the above-synthesized all-silicon ZSM-5 150 grams of zeolite molecular sieve was placed in the mixed aqueous solution, modified at 190°C for 48 hour...

Embodiment 2

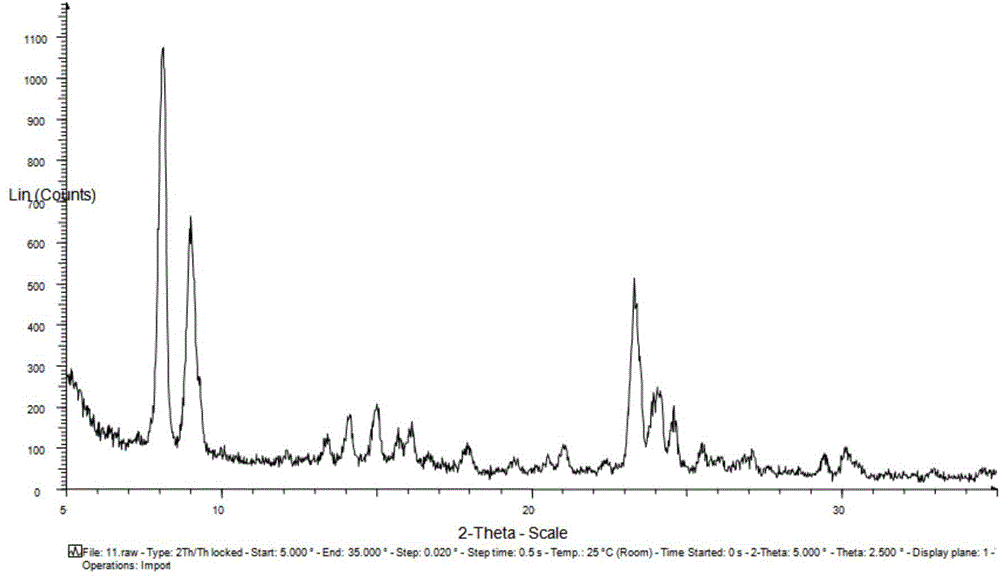

[0040] 650 grams of 30% silica sol, add 550 grams of deionized water, 450 grams of 25% tetrapropylammonium hydroxide aqueous solution, 120 grams of 25% ammonia, 200 grams of tetrapropylammonium bromide, stir vigorously 2 After hours, it was transferred to an autoclave and heated to 170°C for crystallization for 72 hours, filtered, washed and dried, and calcined at 550°C for 5 hours to obtain the all-silica ZSM-5 zeolite molecular sieve. The XRD spectrum and the scanning electron microscope SEM image are as follows: image 3 , 4 , It is proved that it is a typical MFI zeolite molecular sieve with a crystal grain size of about 300nm. 50 grams of 25% tetrapropylammonium hydroxide aqueous solution, 30 grams of diethylamine and 30 grams of dimethyldiethoxysilane are dissolved in 500 grams of water to obtain a mixed aqueous solution. Take the above-synthesized all-silicon ZSM-5 150 grams of zeolite molecular sieve was placed in the mixed aqueous solution at 155°C for 72 hours for modi...

Embodiment 3

[0042] Take 650 grams of ethyl orthosilicate, hydrolyze it with 530 grams of water and 700 grams of 25% tetrapropylammonium hydroxide aqueous solution for one hour, then heat it up to 70°C and remove the alcohol for 2 hours, then transfer the colloid to the autoclave The temperature was raised to 170°C for crystallization for 60 hours, filtered, washed and dried, and calcined at 550°C for 5 hours to obtain a full-silica ZSM-5 zeolite molecular sieve. 80 grams of 25% tetrapropylammonium hydroxide aqueous solution, 15 grams of diethylamine and 30 grams of dimethyldiethoxysilane are dissolved in 500 grams of water to obtain a mixed aqueous solution. Take the above-synthesized all-silicon ZSM-5 150 grams of zeolite molecular sieve was placed in the mixed aqueous solution at 170°C for 48 hours for modification treatment, filtered, washed and dried. Mix the modified zeolite molecular sieve with 105 grams of silica gel, add 150 milliliters of 1N nitric acid, knead and extrude into a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com