Modified teflon preparation method and obtained product thereof

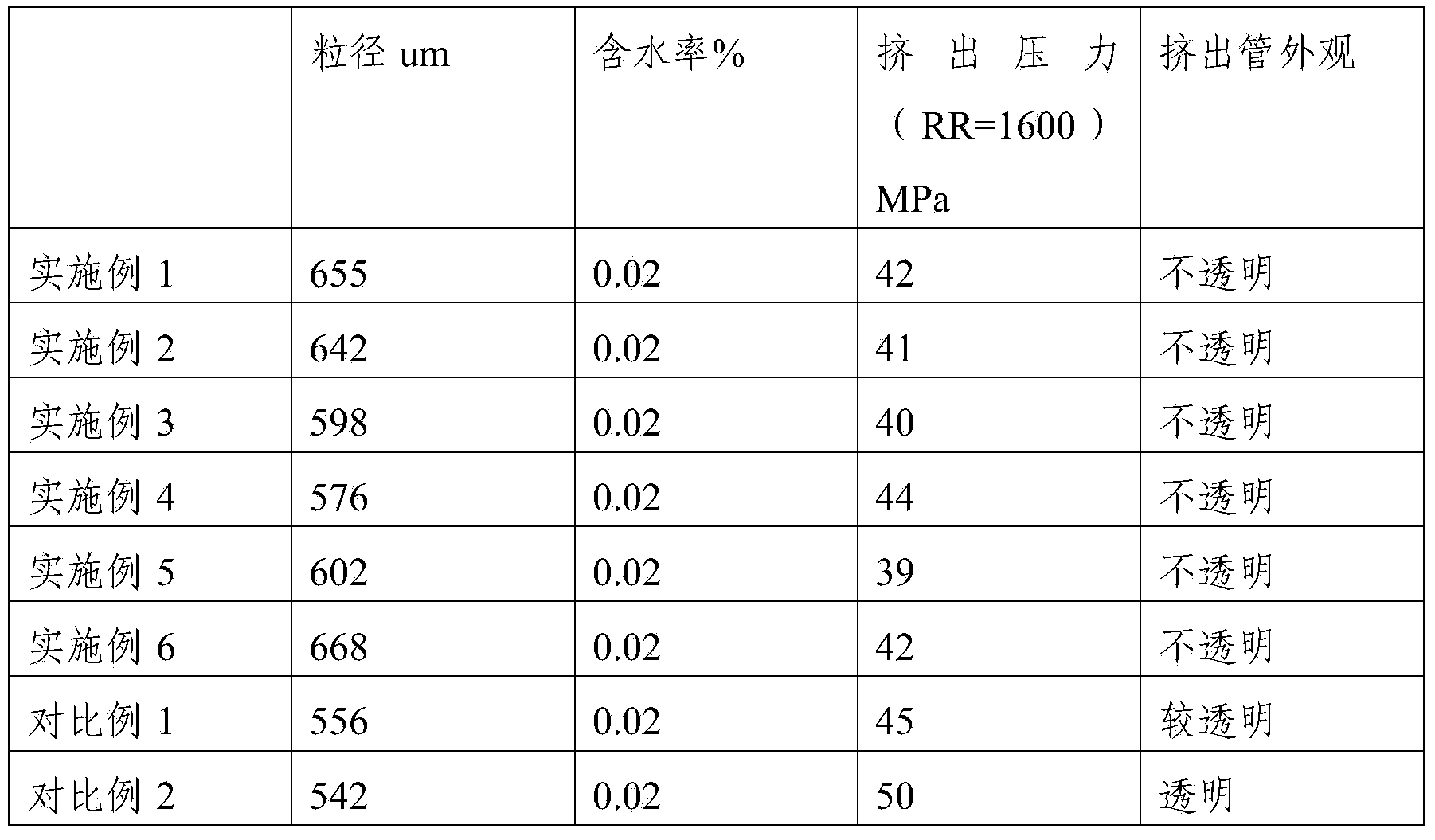

The technology of polytetrafluoroethylene and tetrafluoroethylene is applied in the field of preparation of fluorine-containing polymers, which can solve the problems of relatively transparency and poor whiteness of extruded tubes, and achieve the effects of excellent performance, good whiteness and stable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Process A: In a 5L stainless steel autoclave equipped with a jacket and stirring, after cleaning the autoclave, add 2.8L deionized water, 84g solid paraffin (melting point: 56-58°C), 0.84g succinic acid, 80g Ammonium perfluorooctanoate dispersant, cover the lid of the kettle, start stirring, vacuumize, and replace with nitrogen. Until the oxygen content in the kettle is less than 30ppm, control the temperature in the kettle to 70°C, feed tetrafluoroethylene monomer, add 0.01g ammonium persulfate initiator, control the reaction pressure to 2.5MPa, start the reaction, and control the temperature in the kettle during the reaction. The highest temperature was 90°C. After 0.5 hours of reaction, the reaction was stopped to obtain a homopolymer emulsion with a solid content of 8%.

[0031] Process B: In the same reaction kettle as above, add 2.8 L of the homopolymer emulsion obtained in the process A, cover the kettle, vacuumize, and replace with nitrogen. Until the oxygen co...

Embodiment 2

[0034] Process A: the same as process A in Example 1, except that 2.4L of deionized water, 0.28g of succinic acid, and 0.0084g of ammonium persulfate were added in the reactor, and the solid content of the obtained homopolymer emulsion was 2%.

[0035] B process: with the B process in embodiment 1, difference is to add the homopolymer latex obtained in 2.4LA process, 2g hexafluoropropylene, 0.012g ammonium persulfate initiator, reaction times 3.5 hours, the dispersion liquid solid content that makes is 31 %.

[0036] The copolymerized dispersion is diluted, coagulated and dried after post-treatment (the drying temperature is controlled at 180° C.), and the water content in the resin is controlled below 0.03%. The modified polytetrafluoroethylene dispersion resin is obtained, which is used for paste extrusion processing capillary, and the obtained product has neatness, smoothness, good whiteness, and opacity.

Embodiment 3

[0038] A process: with the A process in Example 1, the difference is that the addition of ammonium perfluorooctanoate is 1.6g, the initiator ammonium persulfate is 0.014g, solid paraffin 28g, the reaction time is 0.4 hours, and the solid content of the gained homopolymer emulsion is 5%.

[0039] Process B: Same as process B in Example 1, except that 2 g of hexafluoropropylene was added, and the solid content of the resulting dispersion was 25%.

[0040] The copolymerized dispersion is diluted, coagulated and dried after post-treatment (the drying temperature is controlled at 180° C.), and the water content in the resin is controlled below 0.03%. The modified polytetrafluoroethylene dispersion resin is obtained, which is used for paste extrusion processing capillary, and the obtained product has the advantages of neatness, smoothness, good whiteness, and opacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com