Flue gas low temperature denitration cobalt manganese oxide catalyst and preparation method thereof

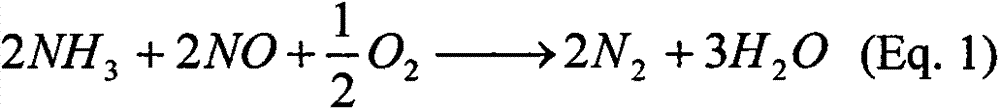

A technology of cobalt manganese oxide and catalyst, which is applied in the field of flue gas low-temperature denitrification catalyst and its preparation, can solve the problems of pollution, high preparation cost, and unsuitability for industrial application, and achieve high denitrification efficiency, low cost, and simple composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

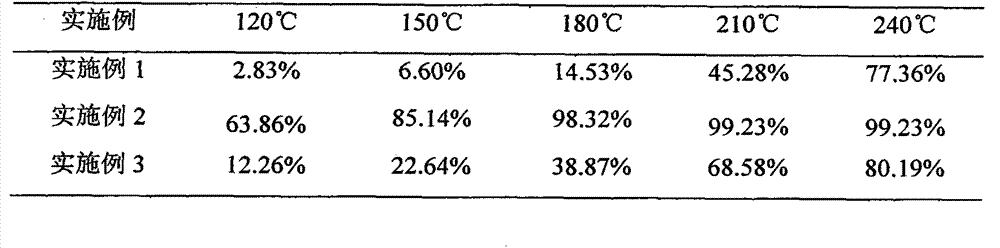

Embodiment 1

[0024] The specific steps of a preparation method of a flue gas low-temperature denitrification cobalt manganese oxide catalyst are as follows:

[0025] (1) prepare the mixed aqueous solution of cobalt salt and manganese salt

[0026] With cobalt nitrate hexahydrate and manganese acetate tetrahydrate as raw materials, according to the volume (L) of deionized water: manganese ions (Mn 2+ ) in moles (mol): cobalt ions (Co in cobalt salts 2+ ) moles (mol) ratio of 1:0.3:0.7 ratio, the manganese salt and cobalt salt were added to deionized water, stirred until dissolved, a mixed solution of cobalt salt and manganese salt was prepared.

[0027] (2) Preparation of precipitant solution

[0028]After the (1) step is completed, take anhydrous sodium carbonate as precipitant, according to the volume (L) of deionized water: the ratio of the mass (g) of anhydrous sodium carbonate precipitant is the ratio of 1: 106, anhydrous The sodium carbonate precipitating agent is added into deioni...

Embodiment 2

[0032] A preparation method of a flue gas low-temperature denitrification cobalt manganese oxide catalyst. The specific steps are the same as in Example 1, wherein:

[0033] Volume (L) of deionized water in step (1): manganese ions in manganese salt (Mn 2+ ) in moles (mol): cobalt ions (Co in cobalt salts 2+ ) to moles (mol) ratio of 1:0.5:0.5.

Embodiment 3

[0035] A preparation method of a flue gas low-temperature denitrification cobalt manganese oxide catalyst. The specific steps are the same as in Example 1, wherein:

[0036] Volume (L) of deionized water in step (1): manganese ions in manganese salt (Mn 2+ ) in moles (mol): cobalt ions (Co in cobalt salts 2+ ) The ratio of the number of moles (mol) is 1:0.7:0.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com