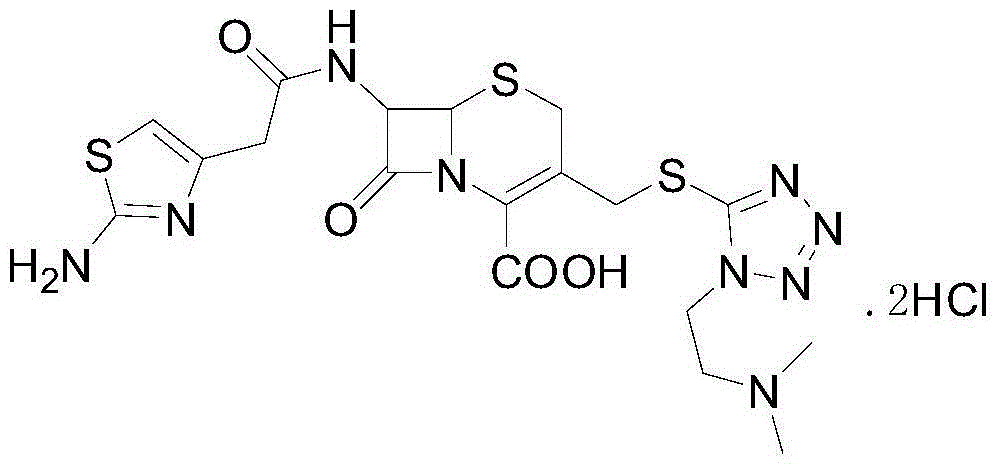

Method for preparing cefotiam hydrochloride

A technology of cefotiam hydrochloride and 7-ACA, which is applied in the field of pharmaceutical antibiotics, can solve the problems of insufficient product recovery, long processing cycle, and high labor intensity, so as to improve equipment use efficiency, labor efficiency, and stable yield Controllable and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

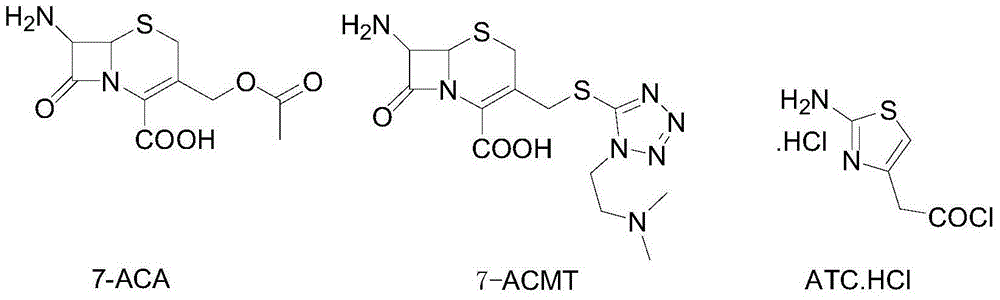

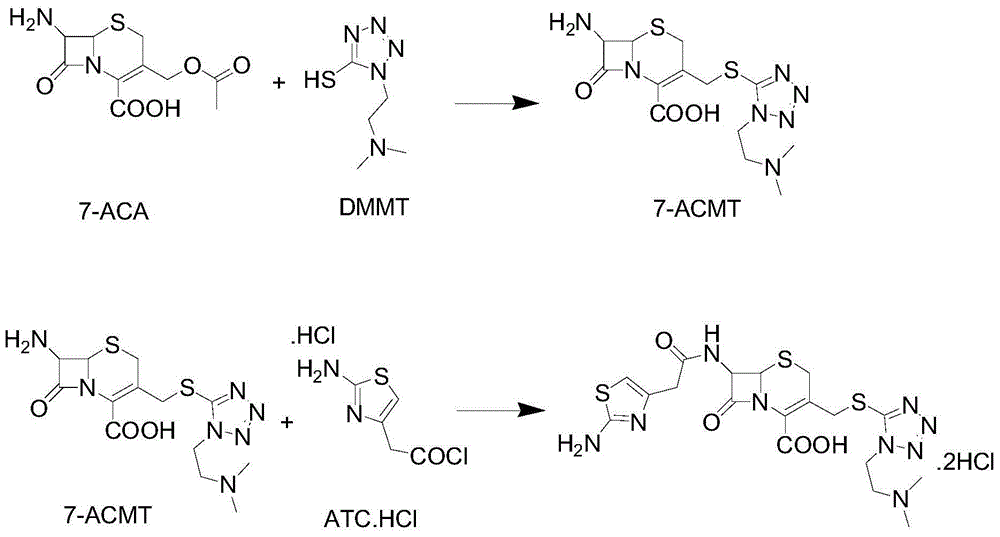

Method used

Image

Examples

Embodiment 1

[0034] In a 500 ml clean and dry four-necked reaction flask, add 100 ml of acetonitrile, 25 g (0.092 mol) of 7-ACA, and 17.5 g (0.101 mol) of DMMT, stir and suspend, cool down to 0-5 °C in a cold bath, and drop in trifluoride 120 g of boronacetonitrile complex (mass concentration 19%, 0.209 mol) was dropped, and the temperature of the water bath was raised to 25-30° C. to react for 2 hours. After the reaction, 50 ml of purified water was added dropwise, and the pH of triethylamine was adjusted to 7.5 to obtain clarification. Transparent reaction solution, continue to cool down to -15°C, add 23.5 grams (0.110mol) of ATC.HCl in batches, keep the temperature for 1 hour, add 60 ml of dichloromethane and 40 grams of refined hydrochloric acid after the reaction, stir for 10 minutes and then let it stand Layering, the temperature of the layered water layer was raised to 15-20°C, 600 milliliters of acetone was added, stirred at 15-25°C for 2.5 hours, filtered, washed with acetone, and ...

Embodiment 2

[0036]In a 500 ml clean and dry four-necked reaction flask, add 120 ml of acetonitrile, 25 g (0.092 mol) of 7-ACA, and 18.5 g (0.107 mol) of DMMT, stir and suspend, cool down to 0-5 °C in a cold bath, and drop in trifluoride 130 grams of boroacetonitrile complex (mass concentration 19%, 0.226mol) was dropped, and the water bath was heated to 25-30°C for 2 hours of reaction. After the reaction, 50 ml of purified water was added dropwise, and 10% sodium carbonate aqueous solution was adjusted to pH=8.2. To obtain a clear and transparent reaction solution, continue to cool down to -20°C, add 24.5 grams (0.115 mol) of ATC.HCl in batches, keep the temperature for 1 hour, add 60 ml of dichloromethane and 45 grams of refined hydrochloric acid after the reaction, and stir for 10 minutes Leave to stand for stratification, heat up the layered water layer to 15-20°C, add 650 milliliters of acetone, stir at 15-25°C for 2 hours, filter, wash with acetone, and dry in vacuo to obtain 47.5 gra...

Embodiment 3

[0038] Into a 500 ml clean and dry four-necked reaction flask, add 120 ml of acetonitrile, 25 g (0.092 mol) of 7-ACA, 18.0 g (0.104 mol) of DMMT, stir and suspend, cool down to 0-5 °C in a cold bath, and drop in trifluoride 110 g of boronacetonitrile complex (mass concentration 19%, 0.191 mol) is dropped, and the temperature of the water bath is raised to 25-30° C. for 2 hours. After the reaction is completed, 50 ml of purified water is added dropwise, and the pH of 10% potassium bicarbonate aqueous solution is adjusted to 8.5 , to obtain a clear and transparent reaction solution, continue to cool down to -23 ° C, add ATC.HCl 24.5 grams (0.115mol) in batches, keep the temperature for 1 hour, add 60 ml of dichloromethane and 45 grams of refined hydrochloric acid after the reaction, and stir for 10 minutes After standing still for stratification, the layered water layer was heated to 15-20°C, 630 ml of ethanol was added, stirred at 15-25°C for 3 hours, filtered, washed with ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com