Tacrolimus suspending eye drop liquid and preparation method thereof

A technology for tacrolimus and eye drops, which is used in liquid delivery, pharmaceutical formulations, emulsion delivery, etc., can solve the problems of rising impurity content, high equipment requirements, thermal instability, etc., to achieve stable product quality and preparation. The process is simple and the effect of avoiding toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

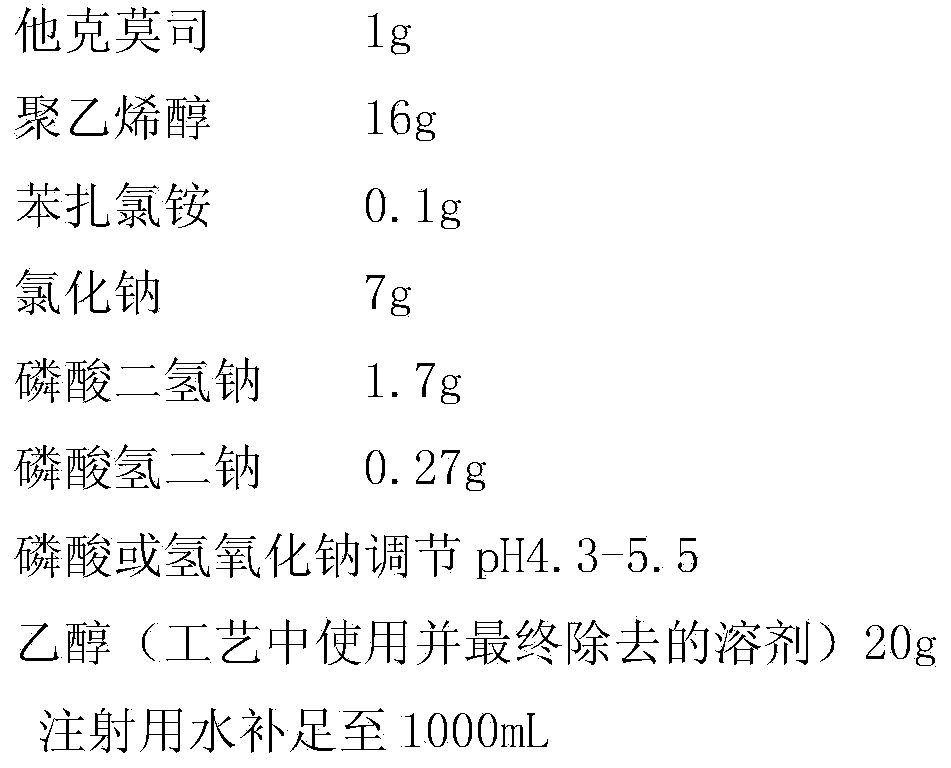

[0063] Embodiment 1, the preparation of 0.1% tacrolimus suspension eye drops (0.1% refers to 0.1g / 100mL, i.e. 1mg / mL; the same below) prescription:

[0064]

[0065] Preparation Process:

[0066] (1) Weigh the prescribed amount of tacrolimus, add it to ethanol and stir to dissolve, filter and sterilize through a 0.2μm filter membrane to obtain a sterile filtrate; in a sterile environment, add the filtrate to 200mL water for injection to precipitate tacrolimus Moss particles (particle size D 90 1.0 μm), the ethanol solvent was removed by diafiltration through a tangential flow ultrafiltration device, and 4-6 times the volume was diafiltered to obtain a sterile suspension of tacrolimus particles;

[0067] (2) Weigh the polyvinyl alcohol of the prescribed amount, add it to 700mL water for injection, heat and stir to dissolve, add benzalkonium chloride, sodium chloride, sodium dihydrogen phosphate, and disodium hydrogen phosphate, and stir to dissolve, add phosphoric acid or ...

Embodiment 2、01

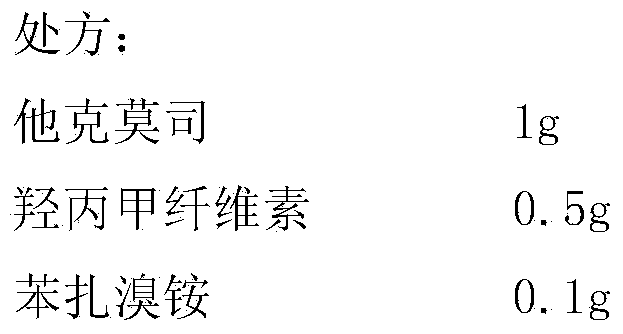

[0070] Example 2, Preparation of 0.1% Tacrolimus Suspension Eye Drops

[0071]

[0072]

[0073] Preparation Process:

[0074] (1) Weigh the prescribed amount of tacrolimus and add it to ethyl acetate, stir and dissolve, filter and sterilize through a 0.2 μm filter membrane to obtain a sterile filtrate, add the filtrate to 300ml of water for injection in a sterile environment, and separate out tacrolimus Crolimus microparticles (average particle size D 90 1.3 μm), the ethyl acetate solvent was removed by washing and filtering through a tangential flow ultrafiltration device, and 4-6 times the volume was washed and filtered to obtain a sterile suspension of tacrolimus particles;

[0075] (2) Weigh 0.5 g of hypromellose in the prescribed amount, add it to 300 ml of water for injection, stir to dissolve, and sterilize by moist heat at 121 ° C for 30 min,

[0076] (3) Weigh 0.1 g of benzalkonium bromide, 3.5 g of sodium dihydrogen phosphate, and 0.85 g of disodium hydrogen...

Embodiment 3、01

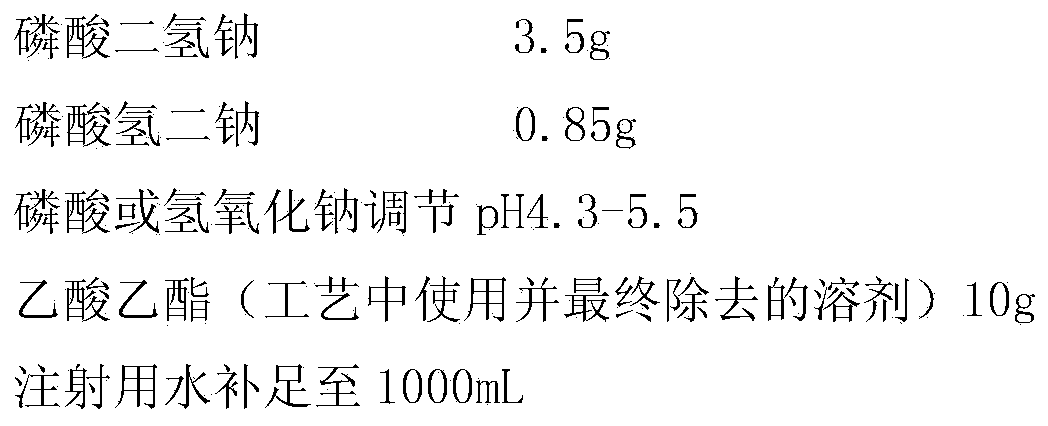

[0101] Example 3, Preparation of 0.1% Tacrolimus Suspension Eye Drops

[0102] prescription:

[0103]

[0104] Preparation Process:

[0105] (1) Weigh the prescribed amount of tacrolimus, add it to ethanol and stir to dissolve, filter and sterilize through a 0.2μm filter membrane to obtain a sterile filtrate; in a sterile environment, add the filtrate to 400mL water for injection to precipitate tacrolimus Moss particles (particle size D 90 0.5 μm), remove the ethanol solvent by washing and filtering through a tangential flow ultrafiltration device, wash and filter 4-6 times the volume, and concentrate the feed solution to 200-300ml to obtain a sterile suspension of tacrolimus particles;

[0106] (2) Weigh the polyvinyl alcohol of the prescribed amount, add it to 700mL water for injection, heat and stir to dissolve, add benzalkonium chloride, sodium chloride, sodium dihydrogen phosphate, and disodium hydrogen phosphate, and stir to dissolve, add phosphoric acid or Sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com