Lincomycin hydrochloride breast injectant for dairy cow and preparation method thereof

A technology of lincomycin hydrochloride and udder injection, which is applied in the field of lincomycin hydrochloride udder injection for dairy cows and its preparation, and can solve the problem of stability, biocompatibility, low release of active ingredients, and content of active ingredients Low, unsatisfactory therapeutic effect, etc., to achieve the effect of increased release of active ingredients and bioavailability, long action time, and suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

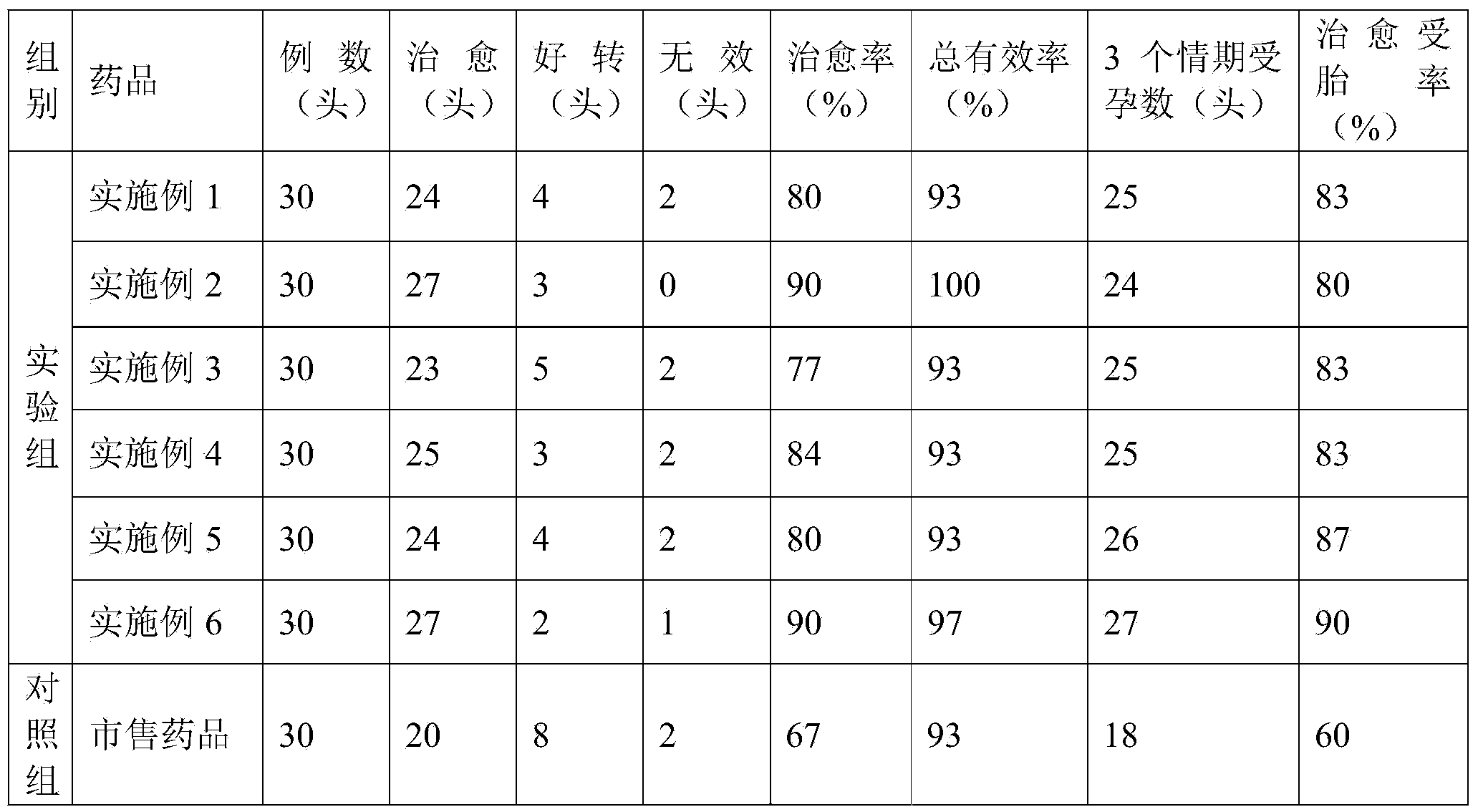

Examples

Embodiment 1

[0034] In this embodiment, the lincomycin hydrochloride udder injection for cows contains the following components in every 100mL injection: lincomycin hydrochloride 6.0g, aluminum stearate 2.0g, Span-80 1.0g, a- Tocopherol 0.05g, soybean lecithin 0.5g, benzyl alcohol 1.0ml, and the balance is soybean oil for injection.

[0035] The preparation method of lincomycin hydrochloride udder injection for dairy cows in this embodiment is as follows:

[0036] 1) Take 20% of the prescription amount of sterilized soybean oil for injection, raise the temperature to 120°C, heat and stir, and add carboxymethylcellulose sodium at the same time, until a transparent gel system is formed, stop stirring, and keep it for 30 minutes Stop heating to form oil glue A;

[0037] 2) Take 10% of the prescription amount of sterilized soybean oil for injection, raise the temperature to 125°C, heat and stir, add lincomycin hydrochloride, α-tocopherol, soybean lecithin, Span-80, and wait for soybean egg T...

Embodiment 2

[0041] In this example, the lincomycin hydrochloride breast injection for dairy cows contains the following components per 100 mL: lincomycin hydrochloride 6.0 g, PEG-4000 1.0 g, Span-80 0.5 g, a-tocopherol 0.1 g, Soybean lecithin 1.2g, benzyl alcohol 3.0ml, and the balance is soybean oil for injection.

[0042] The preparation method of lincomycin hydrochloride udder injection for dairy cows in this embodiment is as follows:

[0043] 1) Take 20% of the prescription amount of sterilized soybean oil for injection, raise the temperature to 115°C, heat and stir, and add PEG-4000 at the same time, until a transparent gel system is formed, that is, oil gel, stop stirring and keep for 40 minutes Then stop heating to form oil glue A;

[0044] 2) Take 10% of the prescription amount of sterilized soybean oil for injection, raise the temperature to 120°C, heat and stir, add lincomycin hydrochloride, α-tocopherol, soybean lecithin, Span-80, and wait for the soybean egg The phospholipid...

Embodiment 3

[0048]Lincomycin hydrochloride udder injection for cows in this example contains the following components per 100 mL: 6.0 g lincomycin hydrochloride, 2.0 g aluminum stearate, 1.0 g PEG-4000, 3.0 g RC-A591NF , lecithin 0.2g, ascorbyl palmitate 0.001g, benzyl alcohol 5ml, and the balance is soybean oil for injection.

[0049] The preparation method of lincomycin hydrochloride udder injection for dairy cows in this embodiment is as follows:

[0050] 1) Take 20% of the prescription amount of sterilized soybean oil for injection, raise the temperature to 125°C, heat and stir, and add PEG-4000 at the same time, until a transparent gel system is formed, that is, oil gel, stop stirring and keep for 20 minutes Then stop heating to form oil glue A;

[0051] 2) Take 10% of the prescription amount of sterilized soybean oil for injection, raise the temperature to 115°C, heat and stir, add lincomycin hydrochloride, α-tocopherol, soybean lecithin, Span-80, and wait for the soybean egg The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com