Preparation method of ultralow platinum-loading capacity Pt-CoP/C anode electrocatalyst for high-activity high-stability direct methanol fuel cell

A methanol fuel cell, high-stability technology, used in fuel cells, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low methanol oxidation activity and high price of precious metal platinum , to achieve the effect of excellent electrochemical performance, simple operation and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Add 0.60g of cobalt chloride hexahydrate and 1.6889g of Vulcan XC-72 produced by American Cabot Company into a beaker containing 50mL of secondary water, ultrasonicate for 30min, stir for 60min, then put it in a muffle furnace and evaporate to dryness at 120°C Moisture content to obtain a black mixture, then 2.016g of the black mixture and 1.32g of sodium hypophosphite hydrate were added to a quartz boat, placed in a tube furnace, and calcined at 800°C for 60min in a nitrogen atmosphere, wherein the oxygen flow rate was 80cc min -1 , tube furnace from room temperature to 5 ℃ min -1 The heating rate was increased to 800° C., and the prepared composite carrier was marked as CoP / C-10% (wherein 10% represents the mass percentage of CoP in the composite carrier).

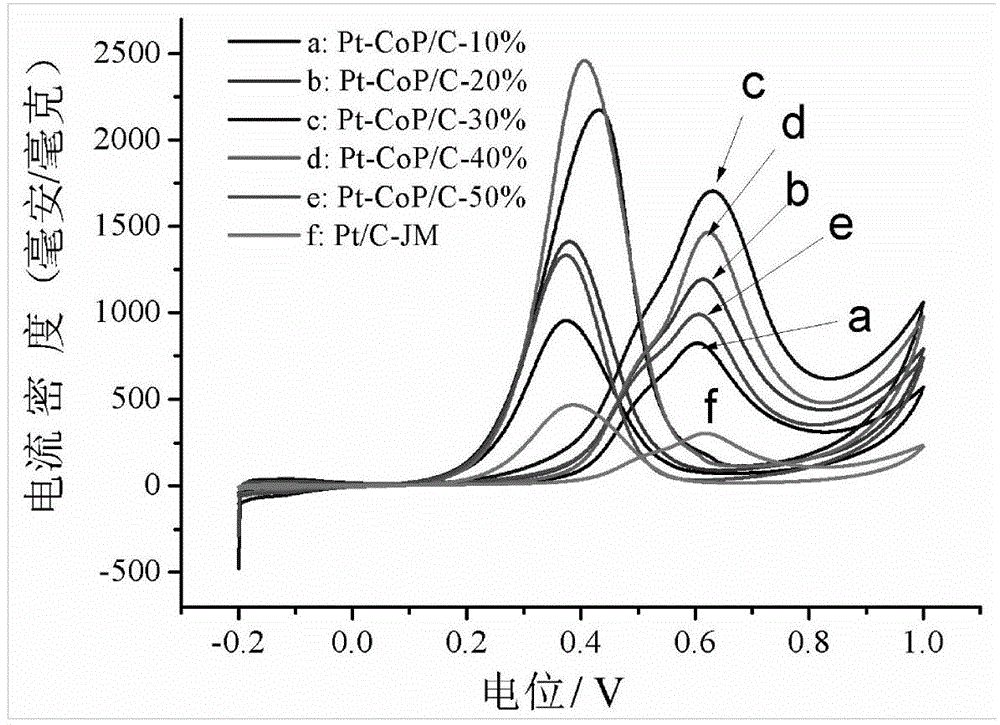

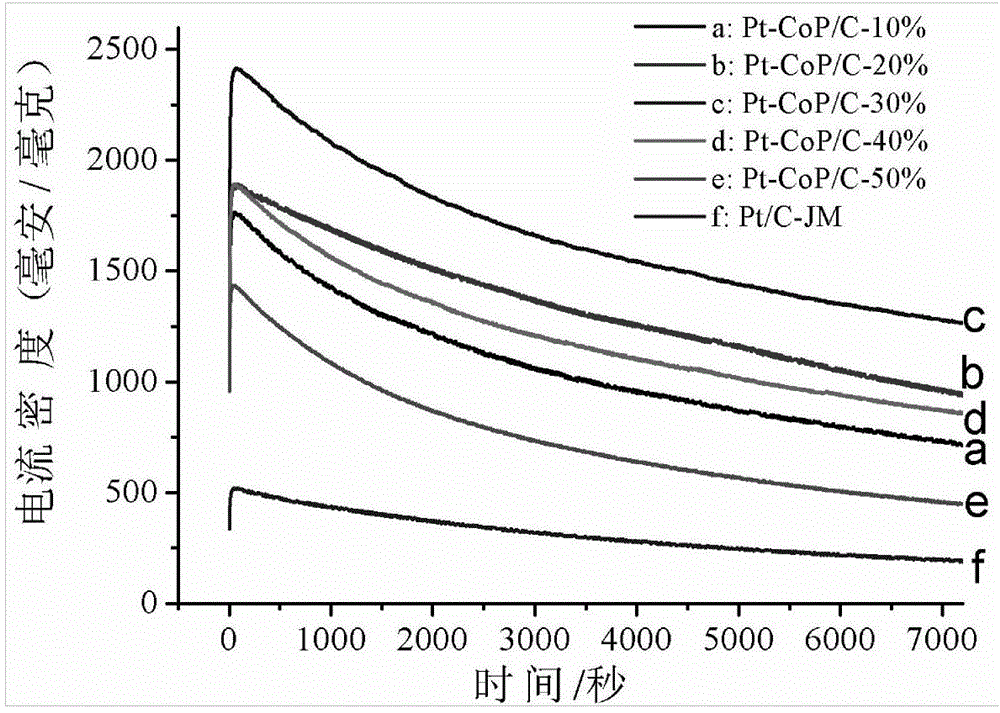

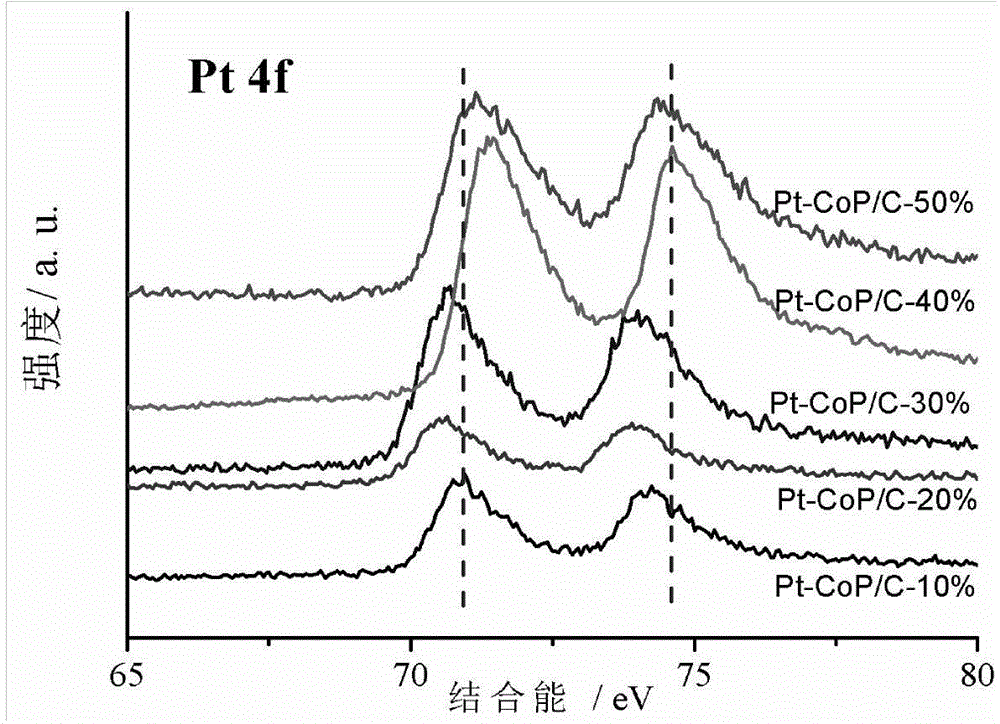

[0048] (2) Weigh 190 mg of CoP / C-10% prepared in step (1), add it into a beaker containing 100 mL of ethylene glycol, and add chloroplatinic acid containing 10 mg of platinum at the same time, stir for 5 h aft...

Embodiment 2

[0064] (1) Add 1.20g of cobalt chloride hexahydrate and 1.5016g of Vulcan XC-72 produced by American Cabot Company into a beaker containing 50mL of secondary water, ultrasonicate for 30min and stir for 60min, then put it in a muffle furnace and evaporate to dryness at 120°C The black mixture was obtained by the water content, and then 2.157g of the black mixture and 2.64g of sodium hypophosphite hydrate were added to a quartz boat, placed in a tube furnace, and calcined at 800°C for 60min in a nitrogen atmosphere, where the oxygen flow rate was 80cc min -1 , tube furnace from room temperature to 5 ℃ min -1 The heating rate was increased to 800° C., and the prepared composite carrier was marked as CoP / C-20% (where 20% represents the mass percentage of CoP in the composite carrier).

[0065] (2) Weigh 190 mg of CoP / C-20% prepared in step (1), add it into a beaker containing 100 mL of ethylene glycol, and add chloroplatinic acid containing 10 mg of platinum at the same time, stir...

Embodiment 3

[0071] (1) Add 1.20g of cobalt chloride hexahydrate and 0.876g of Vulcan XC-72 produced by American Cabot Company into a beaker containing 50mL of secondary water, ultrasonicate for 30min and stir for 60min, then put it into a muffle furnace and evaporate to dryness at 120°C The water content gives a black mixture, and then 1.5313g of the black mixture and 2.64g of sodium hypophosphite hydrate are added to a quartz boat, placed in a tube furnace, and calcined at 800°C for 60min in a nitrogen atmosphere, wherein the oxygen flow rate is 80cc min -1 , tube furnace from room temperature to 5 ℃ min -1 The heating rate was increased to 800° C., and the prepared composite carrier was marked as CoP / C-30% (wherein 30% represents the mass percentage of CoP in the composite carrier).

[0072] (2) Weigh 190 mg of CoP / C-30% prepared in step (1), add it into a beaker containing 100 mL of ethylene glycol, and add chloroplatinic acid containing 10 mg of platinum at the same time, stir for 5 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com