Synthetic paper preparation method based on emulsion polymerization

An emulsion polymerization method and a technology for synthetic paper, applied in the field of synthetic paper preparation, can solve the problem of low mechanical strength of synthetic paper and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

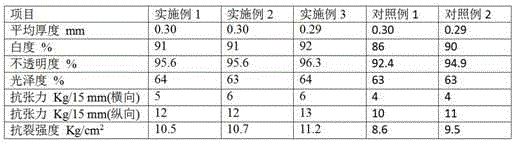

Examples

Embodiment 1

[0029] A method for preparing synthetic paper based on emulsion polymerization, comprising the steps of:

[0030] Step 1. Preparation of prepolymer: Add 80Kg of water and 1Kg of emulsifier into the reactor, stir well, then add 2Kg of divinylbenzene, 1Kg of vinylidene chloride, and 3Kg of acrylocyanide, stir well, then add initiator 0.1Kg, heat for polymerization, then add 1Kg of iron trioxide and 20Kg of powder, stir evenly, obtain polymer after suction filtration, wash the filter cake with ethanol, dry the filter cake to obtain prepolymer, and polymerize The temperature is 70°C, and the polymerization reaction time is 1 hour; the powder is calcium carbonate; the initiator is hydrogen peroxide; the emulsifier is sodium dodecylbenzenesulfonate;

[0031] Step 2, prepolymer, polyethylene 30Kg, polypropylene 10Kg, plant fiber 40Kg, starch 4Kg, surfactant 2Kg, dicumyl peroxide 2Kg, calcium stearate 1Kg, zinc stearate 1Kg, anti Oxygen agent 1Kg, mix well, mixing temperature is 80 ℃...

Embodiment 2

[0035] A method for preparing synthetic paper based on emulsion polymerization, comprising the steps of:

[0036] Step 1. Preparation of prepolymer: Add 100Kg of water and 3Kg of emulsifier into the reactor, stir well, then add 4Kg of divinylbenzene, 3Kg of vinylidene chloride, and 5Kg of acrylocyanide, stir well, then add initiator 0.4Kg, heat for polymerization, then add 2Kg of iron trioxide and 30Kg of powder, stir evenly, obtain polymer after suction filtration, then wash the filter cake with ethanol, dry the filter cake to obtain prepolymer, and polymerize The temperature is 80°C, and the polymerization reaction time is 2 hours; the powder is calcium carbonate; the initiator is hydrogen peroxide; the emulsifier is sodium dodecylbenzenesulfonate;

[0037] Step 2, prepolymer, polyethylene 40Kg, polypropylene 20Kg, plant fiber 60Kg, starch 7Kg, surfactant 3Kg, dicumyl peroxide 4Kg, calcium stearate 2Kg, zinc stearate 2Kg, anti Oxygen agent 2Kg, mix well, mixing temperature ...

Embodiment 3

[0041] A method for preparing synthetic paper based on emulsion polymerization, comprising the steps of:

[0042]Step 1. Preparation of prepolymer: Add 90Kg of water and 2Kg of emulsifier into the reactor, stir well, then add 3Kg of divinylbenzene, 2Kg of vinylidene chloride, and 4Kg of acrylocyanide, stir well, then add initiator 0.3Kg, heat for polymerization, then add 1Kg of iron trioxide and 25Kg of powder, stir evenly, obtain polymer after suction filtration, then wash the filter cake with ethanol, dry the filter cake to obtain prepolymer, and polymerize The temperature is 75°C, and the polymerization reaction time is 2 hours; the powder is calcium carbonate; the initiator is hydrogen peroxide; the emulsifier is sodium dodecylbenzenesulfonate;

[0043] Step 2, prepolymer, polyethylene 35Kg, polypropylene 15Kg, plant fiber 50Kg, starch 6Kg, surfactant 3Kg, dicumyl peroxide 3Kg, calcium stearate 2Kg, zinc stearate 2Kg, anti- Oxygen agent 1Kg, mix well, mixing temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com