High-density zinc oxide based target and preparation method thereof

A zinc oxide-based, high-density technology, which is applied in the field of semiconductor materials, can solve the problems of difficulty in obtaining high-quality and high-density zinc oxide-based targets, difficulty in achieving large size, and increased carbon content in the target, so as to achieve fine grain size and shape Short time, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

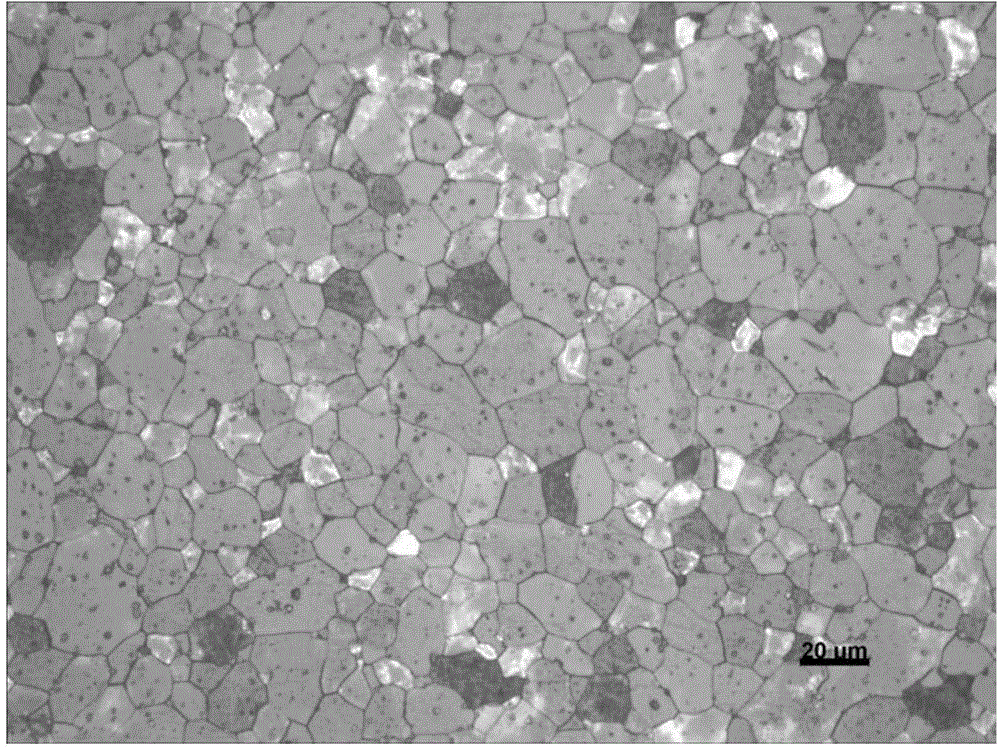

[0036] Embodiment 1 Preparation of pure zinc oxide target material

[0037] Mixing: Weigh 15Kg of zinc oxide powder with a purity of 99.99% and a particle size of 50nm, add 1500g of WR-14 polyvinyl alcohol binder (produced by Nippon Synthetic Chemical Industry Co., Ltd.), and add 20Kg of deionized water to it, and use magnetic Stirring means are mixed with each other evenly; the mixed slurry is dried and pulverized by a spray pulverizing process, so as to obtain a dry mixed powder with uniform particle size distribution, and its average particle size is 15 μm;

[0038] Binder removal and degassing: The dry mixed powder is put into a stainless steel sheath for a flat target, and placed in a degassing furnace for vacuum degassing. The degassing temperature is 400°C, the holding time is 20h, and the vacuum degree is 10 -2 Pa;

[0039] Hot isostatic pressing: Put the degassed package into a hot isostatic pressing furnace for hot isostatic pressing. The hot isostatic pressing temp...

Embodiment 2

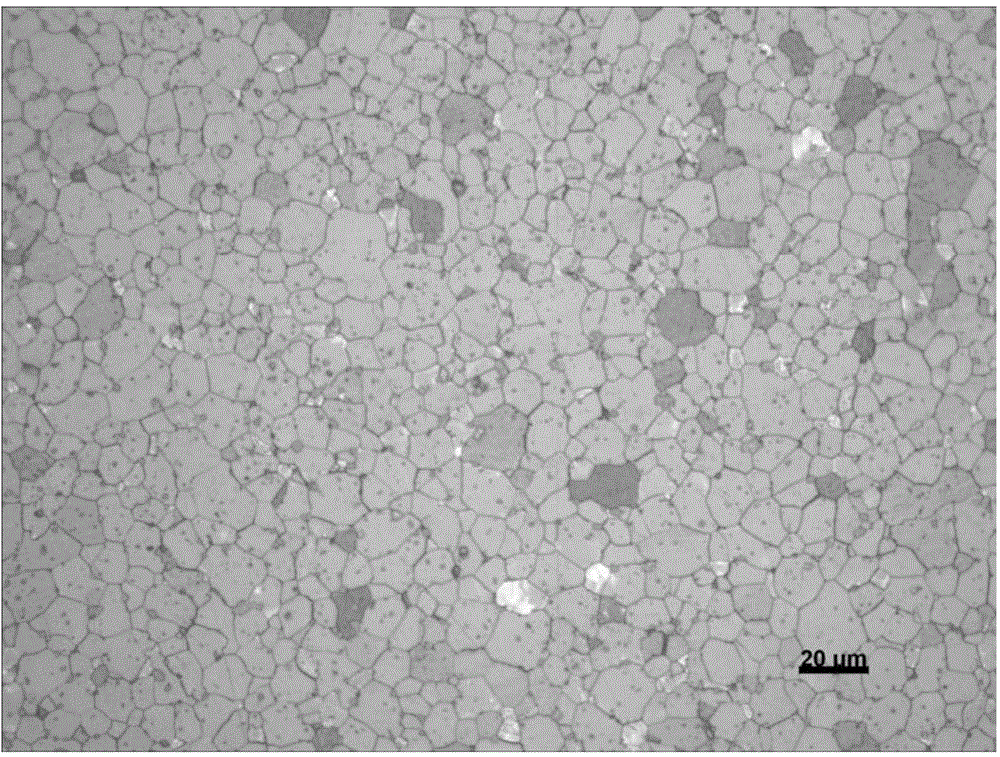

[0043] Example 2 Preparation of indium gallium doped zinc oxide target

[0044] Mixing: Weigh 40Kg of zinc acetate powder with a purity of 99.99% and 8kg of analytically pure urea, and weigh 200g each of indium oxide and gallium oxide powder with a purity of 99.99% and a particle size of 50nm, and add 2.42Kg WR-14 to the above raw materials Polyvinyl alcohol binder (produced by Nippon Synthetic Chemical Industry Co., Ltd.), and 85Kg deionized water was added, and the magnetic stirring means was used to mix each other evenly; the mixed slurry was dried and powdered by spraying powder making process, thereby obtaining Dry mixed powder with uniform particle size distribution, the particle size is 45μm;

[0045] Binder removal and degassing: the dry mixed powder is put into a stainless steel sheath for a flat target, and placed in a degassing furnace for vacuum degassing. The degassing temperature is 650°C, the holding time is 30h, and the vacuum degree is 10 -2 Pa;

[0046] Hot...

Embodiment 3

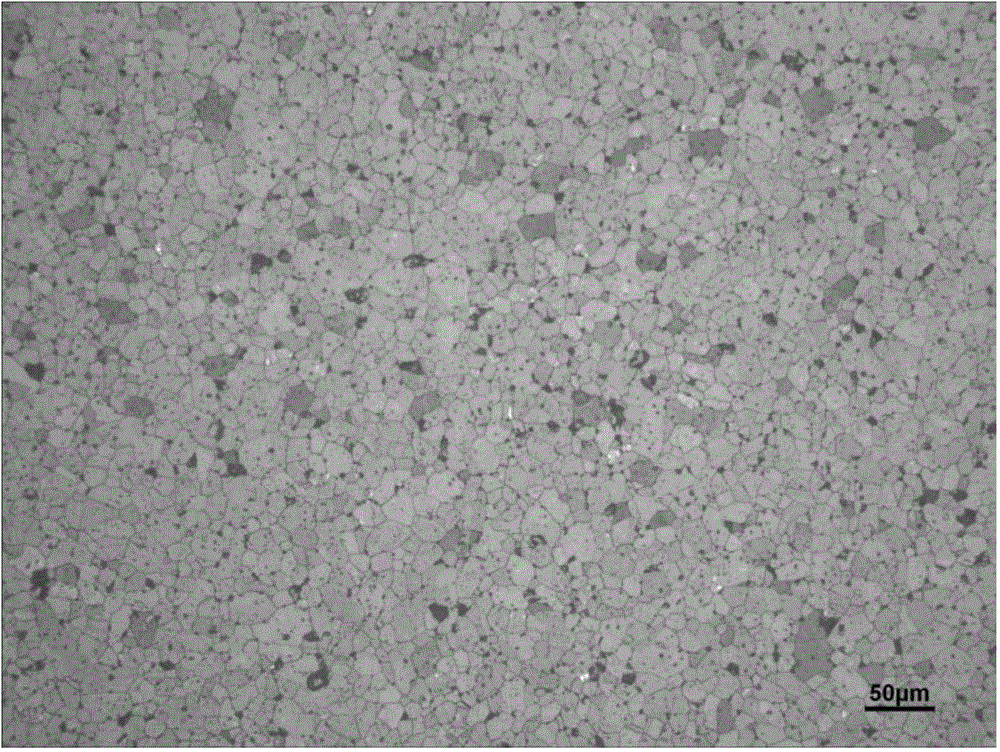

[0050] Example 3 Preparation of boron-doped zinc oxide target

[0051] Mixing: Weigh 48Kg of zinc nitrate with a purity of 99.99% and 9.7kg of analytically pure thiourea, and weigh 120g of boron powder with a purity of 99.9% and a particle size of 1 μm, and add 2.89Kg of WR-14 polyvinyl alcohol viscose to the above raw materials Binder (produced by Nippon Synthetic Chemical Industry Co., Ltd.), and 86.7Kg of deionized water was added, and mixed with each other evenly by means of wet ball milling; the mixed slurry was dried and powdered by spray milling process, so as to obtain the particle size distribution Uniform dry mixed powder with a particle size of 5 μm;

[0052] Binder removal and degassing: the dry mixed powder is put into a stainless steel sheath for a flat target, and placed in a degassing furnace for vacuum degassing. The degassing temperature is 700 ° C, the holding time is 10 hours, and the vacuum degree is 10 -3 Pa;

[0053] Hot isostatic pressing: Put the deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com