Zinc oxide nanowire array structure and preparation method thereof

A zinc oxide nanowire and array structure technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve problems such as unfavorable photoelectric performance, lattice mismatch, structural defects, etc., to avoid structural defects, The effect of reducing production cost and improving photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a zinc oxide nanowire array structure, the method comprising the following steps:

[0029] (1) Put the mixture of zinc oxide, graphite powder and the first dopant into the quartz tube in the tube furnace after grinding, and pass the mixed gas of inert gas and oxygen into the quartz tube to carry out the first Secondary chemical vapor deposition, doped zinc oxide microribbons grown in quartz tubes;

[0030] (2) transferring the doped zinc oxide microribbon in the quartz tube to a silicon wafer, and placing the mixture of zinc powder and the second dopant upstream of the doped zinc oxide microribbon after grinding, and then Put them together into the quartz tube of the tube furnace, and pass the mixed gas of inert gas and oxygen into the quartz tube to carry out the second chemical vapor deposition.

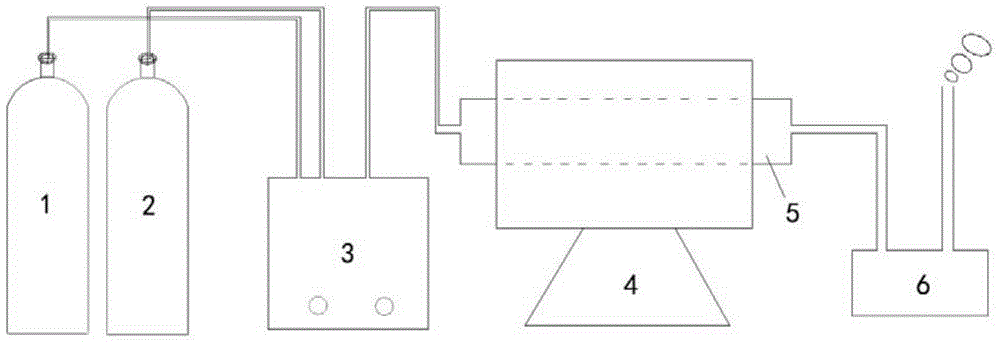

[0031] According to the present invention, the schematic diagram of the chemical vapor deposition apparatus used in the presen...

Embodiment 1

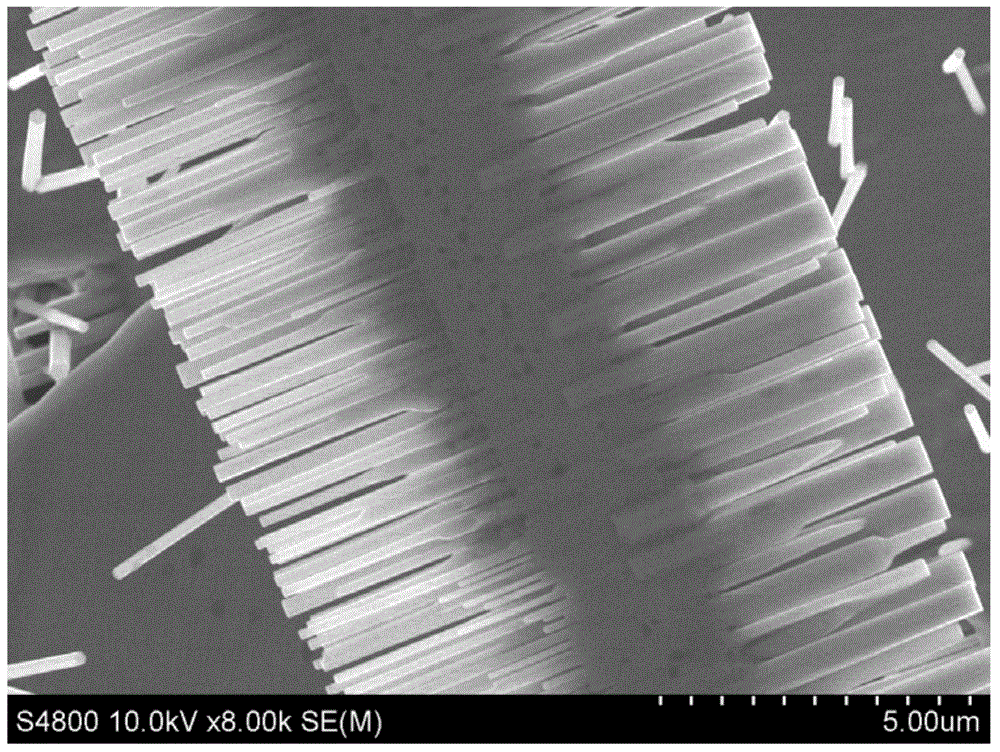

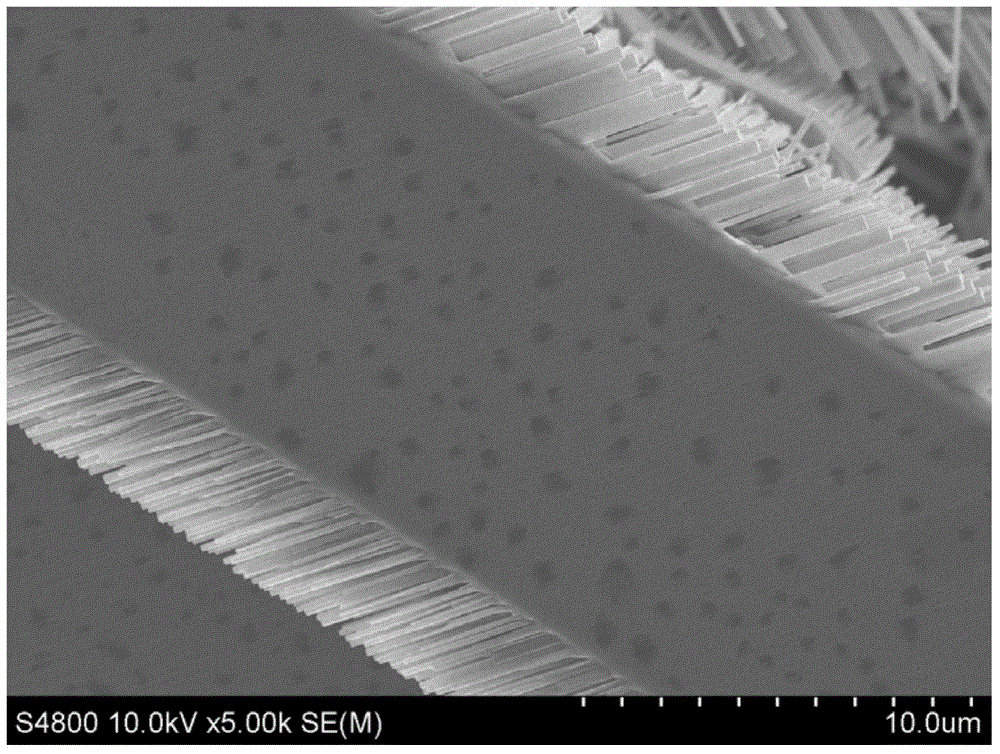

[0045] This embodiment is used to illustrate the zinc oxide nanowire array structure prepared by the method of the present invention

[0046] (1) Preparation of zinc oxide microribbons

[0047] Zinc oxide, graphite powder and lithium chloride are mixed and ground according to the mass ratio of 3:1.5:0.4, and the particle size of the mixture of zinc oxide, graphite powder and lithium chloride after grinding is 1-100 microns, and then the The mixture is placed in a quartz tube, and the quartz tube is placed in the center of the tube furnace; then a mixed gas of argon and oxygen is introduced to carry out the first chemical vapor deposition, wherein the flow rates of argon and oxygen are respectively 100sccm and 0.5sccm; start to heat up from room temperature at a rate of 30 degrees Celsius / minute, rise to the reaction temperature of 900 degrees Celsius, and then keep warm at this temperature for 4 hours, then close the heat preservation program, and the furnace will naturally co...

Embodiment 2

[0052] This embodiment is used to illustrate the zinc oxide nanowire array structure prepared by the method of the present invention

[0053] (1) Preparation of zinc oxide microribbons

[0054] Mix and grind zinc oxide, graphite powder and lithium chloride according to the mass ratio of 2:1:0.3, and the particle size of the mixture of zinc oxide, graphite powder and lithium chloride after grinding is 1-100 microns; then the mixture Put it in a quartz tube, and then place the quartz tube in the center of the tube furnace; then pass a mixed gas of argon and oxygen to carry out the first chemical vapor deposition, wherein the flow rates of argon and oxygen are 150sccm and 1 sccm; start to heat up from room temperature, the heating rate is 35 degrees Celsius / minute, rise to the reaction temperature, that is, 1000 degrees Celsius, and then keep warm at this temperature for 3.5 hours, then close the heat preservation program, and the furnace naturally cools down to room temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com