Glucose oxidase-mediated free radical initiating system and method for preparing hydrogel

A technology of glucose oxidase and triggering system, applied in the field of polymer compounds, can solve the problems affecting the subsequent application of hydrogel, incomplete polymerization of monomers, poor storage stability, etc., achieve excellent mechanical properties and biocompatibility, and formulate Simple and effective in a wide pH range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

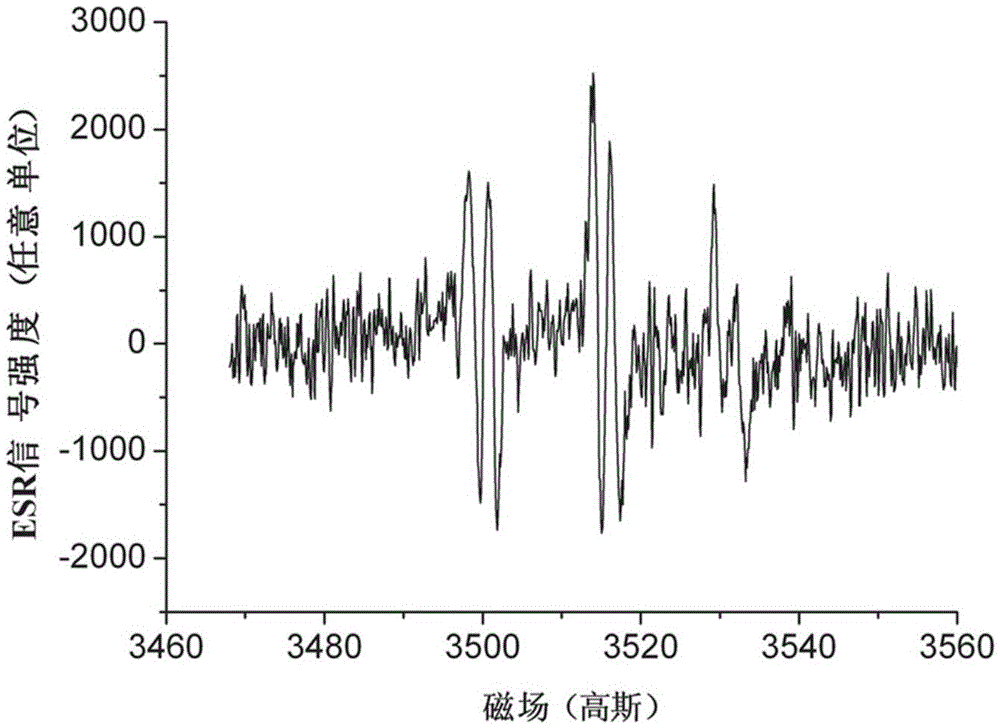

Image

Examples

Embodiment 1

[0029] 1) Preparation of precursor solution: take 0.10-0.13 g of N,N-dimethylacrylamide, 0.07-0.09 g of cross-linking agent polyethylene glycol diacrylate (average molecular weight 250), and 1.3-1.5 g of deionized water into the sample In the bottle, mix evenly with a vortex mixer, and the measured pH value is 7-8.

[0030] 2) Preparation of hydrogel: 100 μL of N-hydroxysuccinimide aqueous solution, 100 μL of glucose oxidase concentrated solution, and 200 μL of glucose aqueous solution were sequentially added to the above precursor solution (N-hydroxysuccinimide and glucose in the reaction system). The molar concentration ratio of glucose and glucose oxidase is 1.74, and the molar concentration ratio of glucose and glucose oxidase is 25000).

Embodiment 2

[0032] 1) Preparation of precursor solution: take N,N-dimethylacrylamide 0.10~0.13g, crosslinking agent polyethylene glycol diacrylate (average molecular weight 250) 0.07~0.09g, deionized water 1.3~1.5g, 1M Add 50 μL of acetic acid aqueous solution into the sample bottle, mix well with a vortex mixer, and the measured pH value is 3.5 to 4.5.

[0033] 2) Preparation of hydrogel: the steps are the same as in Example 1, and the gel formation time is 3min.

Embodiment 3

[0035] 1) Preparation of precursor solution: take N,N-dimethylacrylamide 0.10~0.13g, crosslinking agent polyethylene glycol diacrylate (average molecular weight 250) 0.07~0.09g, deionized water 1.3~1.5g, 1M 125 μL of aqueous ammonia solution was added to the sample bottle, and mixed evenly with a vortex mixer. The measured pH value was 9.5 to 10.5.

[0036] 2) Preparation of hydrogel: the steps are the same as in Example 1, and the gel formation time is 19min30s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com