A kind of production method of preparing denatured starch slurry by biological enzyme

A modified starch and manufacturing method technology, applied in fiber treatment, textile and papermaking, fermentation, etc., can solve the problems of difficult separation of grafted starch products, expensive initiators, low grafting efficiency of products, etc., and shorten the processing time of sizing , product separation is easy, and the effect of avoiding drastic changes in system viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

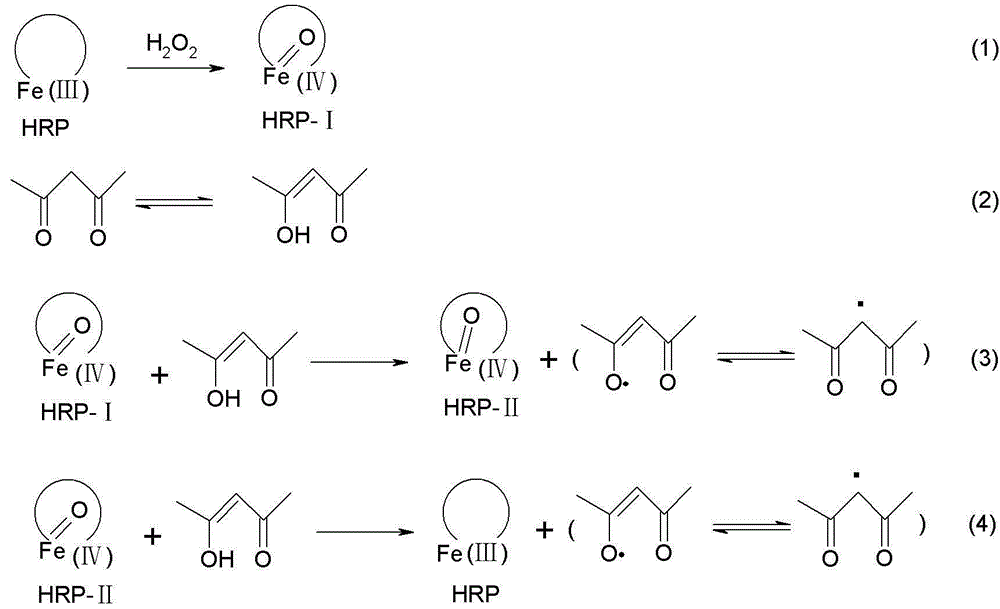

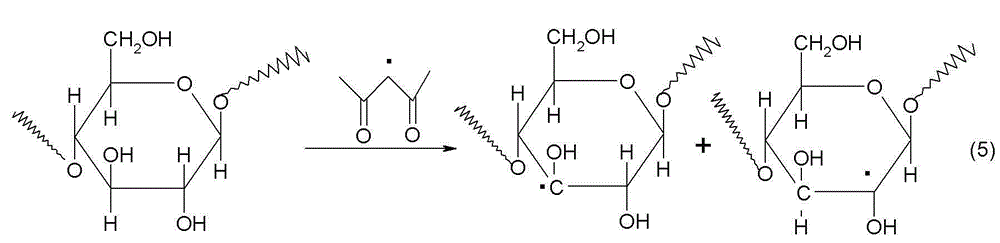

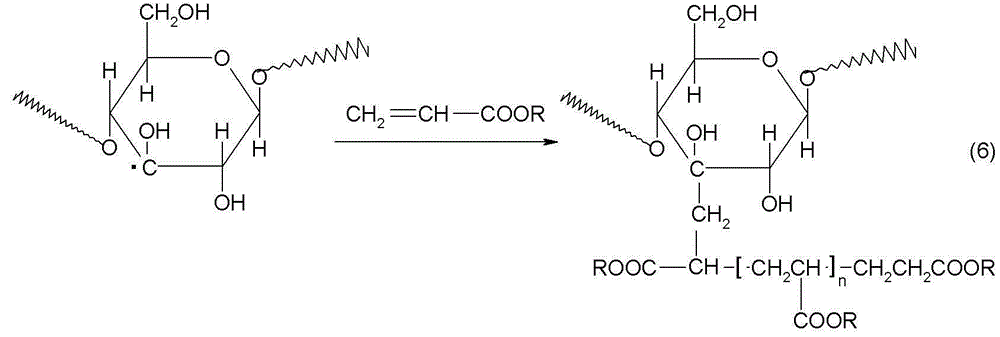

Method used

Image

Examples

Embodiment 1

[0030] Weigh 8.5 g of acrylic acid, add 20% NaOH solution to neutralize the pH of the solution to 5-7, and prepare sodium acrylate solution. The prepared sodium acrylate solution was mixed with 160 g of a solution of 40% acrylic acid as a grafted monomer mixture. Add 500g of ordinary potato starch into deionized water to make starch milk containing 30% starch, put it in an ultrasonic processor at room temperature, raise the temperature to 40°C, turn on the ultrasonic treatment for 20 minutes, adjust the pH value to 4-6 with acetic acid, add deionized 1g of branching enzyme, stirred evenly, incubated at 40°C for 5 hours, then raised the temperature to 80°C for 30 minutes to inactivate the debranching enzyme. Add aqueous sodium bicarbonate solution to the prepared starch milk, adjust the pH value of the reaction system to 8-9, and pass nitrogen gas for 20 minutes to remove dissolved oxygen in the solution. Weigh 25g of acetylacetone and 250mL of HRP with a concentration of 1mg / ...

Embodiment 2

[0033] Weigh 62g of acrylic acid and 13g of butyl acrylate and mix uniformly as graft comonomer. Add 500g of ordinary corn starch into deionized water to make starch milk containing 30% starch, put it into an ultrasonic processor at room temperature, raise the temperature to 40°C, turn on the ultrasonic treatment for 20 minutes, adjust the pH value to 4-6 with acetic acid, add deionized 1g of branching enzyme, stirred evenly, incubated at 40°C for 5 hours, then raised the temperature to 80°C for 30 minutes to inactivate the debranching enzyme. Add aqueous sodium bicarbonate solution to the prepared starch milk, adjust the pH value of the reaction system to 8-9, and pass nitrogen gas for 20 minutes to remove dissolved oxygen in the solution. Weigh 25g of acetylacetone and 250mL of HRP with a concentration of 1mg / L and mix them, add them to the starch milk that has been prepared, and add HRP with a mass concentration of 30% to the system at the same time. 2 o 2 Mix the solutio...

Embodiment 3

[0036] Weigh 18g of acrylic acid and 12g of ethyl acrylate and mix uniformly as graft comonomer. Add 200g of ordinary corn starch into deionized water to make starch milk containing 30% starch, put it in an ultrasonic processor at room temperature, raise the temperature to 40°C, turn on the ultrasonic treatment for 15 minutes, adjust the pH value to 4-6 with acetic acid, add deionized 0.4 g of branched enzyme, stirred evenly, and incubated at 40°C for 3 hours, then raised to 80°C and reacted for 20 minutes to inactivate the debranching enzyme. Add aqueous sodium bicarbonate solution to the prepared starch milk, adjust the pH value of the reaction system to 8-9, and pass nitrogen gas for 15 minutes to remove dissolved oxygen in the solution. Weigh 1g of acetylacetone and 100mL of HRP with a concentration of 1mg / L and mix them, add them to the prepared starch milk, and add HRP with a mass concentration of 30% to the system at the same time. 2 o 2 Mix the solution with the acry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com